Understanding Square Pipe Roll Forming Machines

Square pipe roll forming machines are specialized equipment designed for the efficient production of square and rectangular tubes from various materials, particularly steel. These machines utilize a series of rollers and bending processes to create uniform, high-quality pipes, making them essential in industries ranging from construction to automotive manufacturing.

Working Principle

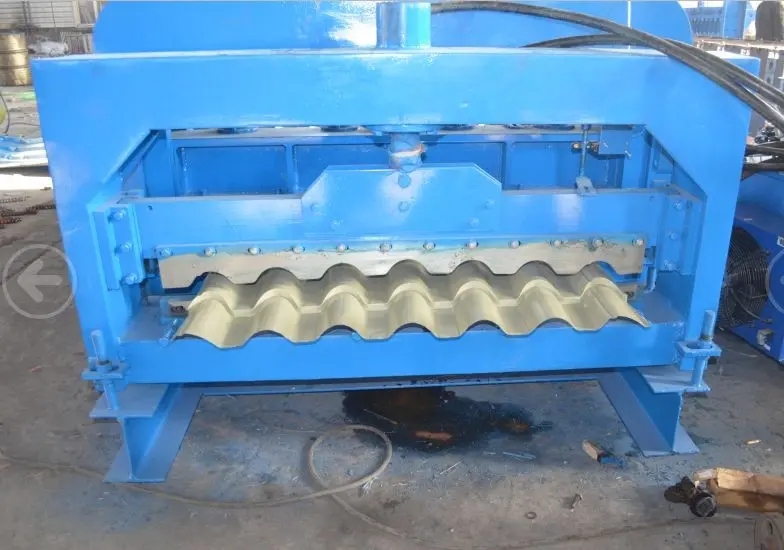

The operation of a square pipe roll forming machine begins with a flat sheet of metal, typically steel or aluminum, being fed into the machine. The material then passes through a series of rollers, each meticulously designed to shape the metal incrementally. As the strip moves through the roller stations, it undergoes bending, forming a square or rectangular profile. The precision of these rollers is critical, as they dictate the final dimensions and wall thickness of the pipe.

After the initial forming process, the pipes are often subjected to further treatments, such as welding, to secure the edges and enhance their structural integrity. The welding techniques employed can vary; some machines use high-frequency welded methods, while others may utilize MIG or TIG welding for more specialized applications. Finally, the formed pipes are cut to the desired lengths, completing the manufacturing process.

Key Advantages

One of the most significant advantages of using square pipe roll forming machines is their efficiency. These machines can produce large quantities of square pipes in a shorter time compared to traditional manufacturing methods. This high throughput ensures that manufacturers can meet market demands without sacrificing quality.

Additionally, roll forming is known for producing products with consistent dimensions and minimal waste. The precision of the rollers means that the formed pipes have uniform thickness and straight edges, which are crucial for their application in load-bearing structures. Moreover, the process is favorable in terms of material usage; since the pipes are formed from flat sheets, there is significantly less scrap material produced.

Applications

Square pipes produced by roll forming machines are used in various applications. In the construction industry, they serve as structural components for frames, supports, and even signage. Their robustness and durability make them ideal for both residential and commercial constructions. Additionally, these pipes can be found in furniture production, where they are used to create sleek, modern designs.

In the automotive sector, square pipes are utilized in the manufacturing of various parts, including chassis and support beams. Their strength-to-weight ratio makes them particularly valuable, as they provide necessary support while minimizing overall vehicle weight.

Conclusion

In conclusion, square pipe roll forming machines are an essential innovation in modern manufacturing. Their ability to produce high-quality, consistent square and rectangular pipes efficiently serves a multitude of industries. As technology advances, we can expect further enhancements in the speed, accuracy, and versatility of these machines, solidifying their role in the ever-evolving landscape of metal fabrication. Investing in such technology not only improves production rates but also enhances product quality, making it a worthy consideration for manufacturers looking to optimize their operations.