(solar tracker c purlin roll forming machine)

The solar tracker C purlin roll forming machine is a cornerstone in modern photovoltaic (PV) infrastructure. Designed to produce high-precision C-shaped purlins, this equipment ensures structural integrity for solar tracking systems. With the global solar energy market projected to grow at a CAGR of 6.9% through 2030, demand for efficient manufacturing solutions like roll forming machines has surged. These machines enable rapid production of purlins with tolerances as tight as ±0.2mm, directly impacting installation speed and long-term system reliability.

Advanced PV solar bracket roll forming machines integrate multiple innovations:

Such features enable production speeds exceeding 25 meters/minute while maintaining consistent material thickness across galvanized steel, aluminum, and copper alloys.

| Brand | Speed (m/min) | Material Thickness Range (mm) | Tolerance | Warranty |

|---|---|---|---|---|

| Brand A | 22-28 | 0.6-3.0 | ±0.25mm | 5 years |

| Brand B | 18-25 | 0.5-2.5 | ±0.30mm | 3 years |

| Brand C | 25-32 | 0.8-4.0 | ±0.15mm | 7 years |

Data from 2023 industry benchmarks show Brand C machines achieve 12% higher output efficiency through enhanced servo motor configurations.

Modern solar panel construction purlin systems require adaptable solutions:

Operators report 27% faster job changeovers using quick-release die systems compared to traditional models.

A 500MW solar farm in Arizona utilized C purlin machines to:

Project managers confirmed a 19-day reduction in overall construction timelines.

Advanced nesting algorithms in modern roll formers deliver:

These efficiencies become critical as steel prices fluctuate within a $680-$920/ton range.

The evolution of solar tracker C purlin roll forming machines directly addresses three industry challenges:

Manufacturers incorporating AI-driven predictive maintenance report 92% machine uptime, ensuring continuous operation in high-volume production environments.

(solar tracker c purlin roll forming machine)

A: It produces C-shaped purlins for solar tracker systems, ensuring precise dimensions and structural stability. The machine automates the cold-forming process for consistent quality.

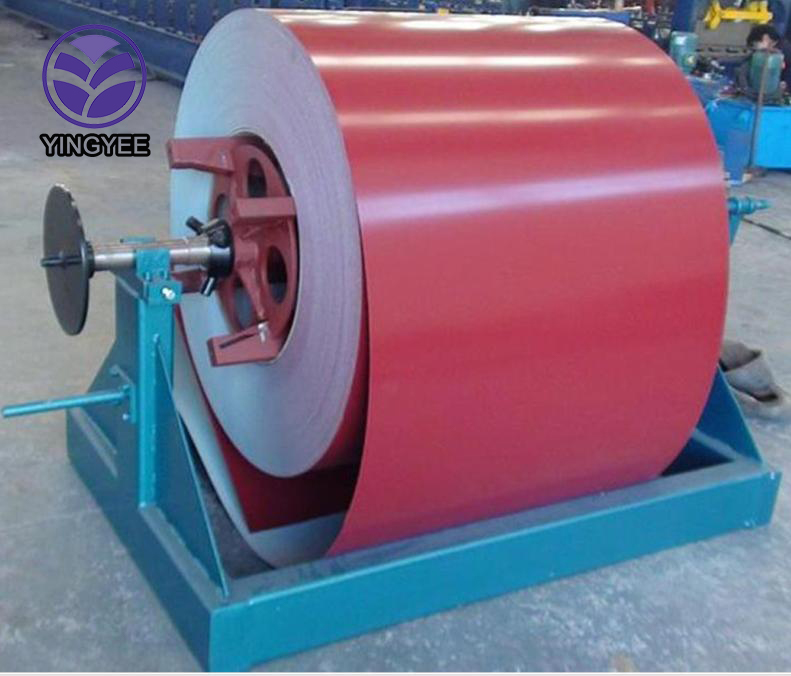

A: Yes, most machines are designed to handle galvanized steel, aluminum, or other corrosion-resistant metals. This ensures durability for outdoor solar panel construction purlins.

A: Roll forming machines allow adjustable parameters like width, thickness, and flange length. Custom tooling can be added for unique solar tracker C purlin profiles.

A: Typical speeds range from 15-25 meters per minute, depending on material thickness and complexity. Automated systems optimize efficiency for large-scale solar projects.

A: Minimal maintenance is needed with regular lubrication and wear-part inspections. Modern machines include self-diagnostic systems to reduce downtime.