The Shelf Rack Upright Roll Forming Machine An Essential Tool for Modern Manufacturing

In the dynamic landscape of modern manufacturing, efficiency and precision are paramount. One of the pivotal innovations that significantly enhance production capabilities is the shelf rack upright roll forming machine. This sophisticated piece of equipment plays a crucial role in creating durable and high-quality uprights for shelving systems, vital for various industries including retail, warehousing, and logistics.

Understanding Roll Forming Technology

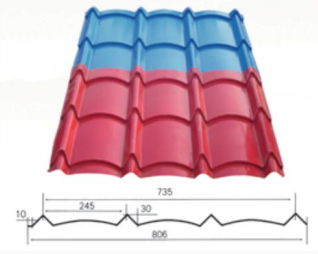

At its core, roll forming is a continuous bending operation in which a long strip of metal, typically steel, is gradually shaped into the desired profile by passing it through a series of rollers. The shelf rack upright roll forming machine utilizes this technology to produce vertical support structures that are essential for the stability and strength of shelving systems. The process begins with flat metal sheets that are fed into the machine, where they are transformed into complex shapes that meet specific design requirements.

Key Features of Shelf Rack Upright Roll Forming Machines

1. Precision Engineering One of the most significant advantages of using a roll forming machine is the high level of precision it offers. The machine is designed to produce consistent dimensions, ensuring that each upright component is identical, which is critical for building sturdy and reliable shelving units.

2. Versatility These machines can be customized to create a variety of profiles to suit different shelving applications. Whether for heavy-duty industrial racks or lightweight retail displays, manufacturers can adjust the design to cater to specific needs.

3. High Production Speed Roll forming machines operate at a remarkable speed compared to traditional manufacturing methods. This high throughput enables manufacturers to meet increasing demands without compromising on quality.

4. Material Efficiency The process minimizes waste since it utilizes continuous sheet metal. The roll forming process can significantly reduce scrap material, making it a cost-effective solution for manufacturers.

5. Robust Construction Most roll forming machines are built with heavy-duty materials that allow for long-term use under demanding conditions. This durability not only enhances the machine’s lifespan but also ensures consistent performance over time.

Applications in Various Industries

The shelf rack upright roll forming machine finds applications in multiple sectors. In the retail industry, it is instrumental in the creation of shelving systems that effectively display products while maximizing available space. Warehousing and logistics operations benefit from the production of robust storage solutions that can handle significant weight, essential for inventory management and distribution.

Additionally, in the automotive and construction industries, custom-designed uprights are used in various applications, ranging from temporary storage racks to permanent structural supports. The adaptability of these machines to manufacture customized solutions has made them indispensable in meeting the ever-changing demands of these industries.

Environmental Considerations

In today's manufacturing landscape, sustainability is becoming increasingly important. The production processes using roll forming technology typically consume less energy compared to traditional manufacturing methods. Additionally, the reduced waste generated contributes to a smaller environmental footprint, aligning with global efforts toward more sustainable production practices.

Conclusion

The shelf rack upright roll forming machine stands as a testament to the advancements in manufacturing technology. With its ability to produce high-quality, precise, and versatile components at high speeds while minimizing material waste, it is a crucial asset in modern production facilities. As industries continue to evolve, the role of such machinery will become even more vital, helping manufacturers meet the demands of an increasingly competitive market. Investing in a shelf rack upright roll forming machine can enhance operational efficiency and provide a competitive edge, ultimately leading to greater business success. In a world that values both quality and sustainability, these machines will continue to be at the forefront of manufacturing innovation.