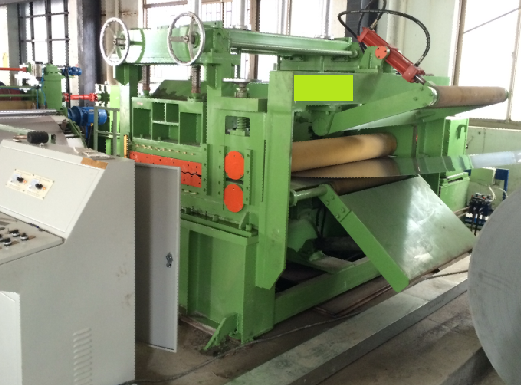

Shelf Rack Upright Roll Forming Machine Revolutionizing Storage Solutions

In today's fast-paced world, efficient storage solutions are paramount for both commercial and industrial sectors. One of the most innovative additions to the industry is the shelf rack upright roll forming machine. This sophisticated equipment streamlines the production of high-quality shelf rack uprights, ultimately transforming how we think about storage and shelving systems.

Understanding the Roll Forming Process

Roll forming is a continuous bending operation in which a long strip of metal is fed through consecutive pairs of rolls. Each set of rolls progressively shapes the metal into the desired cross-section. The beauty of this process lies in its efficiency; it allows for the production of uniform and precise components at high speeds. This is particularly beneficial for shelf rack uprights, which must be both strong and consistent to ensure that they can support a variety of loads safely.

The shelf rack upright roll forming machine does not just enhance the speed of production; it also ensures that the quality of the uprights meets stringent industry standards. Utilizing advanced technologies, such as computerized controls and precision tooling, manufacturers can create uprights that are tailored to specific requirements. Different sizes, shapes, and thicknesses can be achieved without compromising on durability or strength.

Key Features of the Machine

1. High Production Efficiency One of the standout features of the shelf rack upright roll forming machine is its ability to produce large quantities in a fraction of the time required by traditional manufacturing methods. This efficiency translates into lower operational costs and increased profit margins.

2. Customizable Design Modern machines come equipped with software that allows for easy modifications to the design specifications. This flexibility enables manufacturers to respond quickly to market demands and produce different types of uprights as needed.

3. Robust Construction Given that shelf rack uprights must endure significant weight loads, the roll forming machine is built to ensure high structural integrity. The use of high-strength materials and rigorous testing guarantees that the uprights will not fail under pressure.

4. Reduced Material Waste Traditional manufacturing techniques often result in considerable waste material. The roll forming process, however, optimizes the use of raw materials, reducing waste and minimizing costs.

5. Ease of Operation With advancements in automation, modern roll forming machines are user-friendly. Operators can quickly learn to manage and maintain these machines, enabling businesses to focus more on production and less on training.

Applications of Shelf Rack Uprights

Shelf rack uprights are a fundamental component in various applications. They are widely used in warehouses, retail stores, and commercial settings for creating sturdy shelving systems. The modular nature of these uprights allows for versatility in design and configuration, making the storage solutions adaptable to different needs.

In addition to traditional storage solutions, the rise of e-commerce has led to increased demand for efficient warehousing. As businesses shift towards online sales, the requirement for organized and easily accessible storage has surged. The shelf rack upright roll forming machine meets this demand by providing businesses with robust and customizable storage solutions to handle an ever-growing inventory.

The Future of Storage Solutions

As industries evolve and the demand for efficient storage solutions increases, the role of machines like the shelf rack upright roll forming machine will become even more significant. With continued advancements in technology, future machines may incorporate artificial intelligence and machine learning to further optimize production processes.

Moreover, environmental considerations are becoming paramount in manufacturing. As sustainability practices gain traction, manufacturers may seek innovative ways to reduce energy consumption and increase recyclability in the production of shelf rack uprights.

Conclusion

The shelf rack upright roll forming machine is more than just a piece of equipment; it is a game changer in the storage solutions industry. Its efficiency, flexibility, and ability to produce high-quality products position it as an essential tool for manufacturers aiming to meet the demands of modern warehousing and retail environments. As technology progresses, this innovative machine will continue to play a vital role in shaping the future of storage solutions, simplifying our lives, and making efficient use of space.