The Shelf Rack Upright Roll Forming Machine Revolutionizing Storage Solutions

In the modern world, efficient storage solutions are a cornerstone of both commercial and residential spaces. One of the most innovative advancements in this realm has been the development of the shelf rack upright roll forming machine. This machine not only streamlines the production of shelf racks but also enhances their design and durability, making it a crucial asset for manufacturers in the storage solutions industry.

Understanding Roll Forming Technology

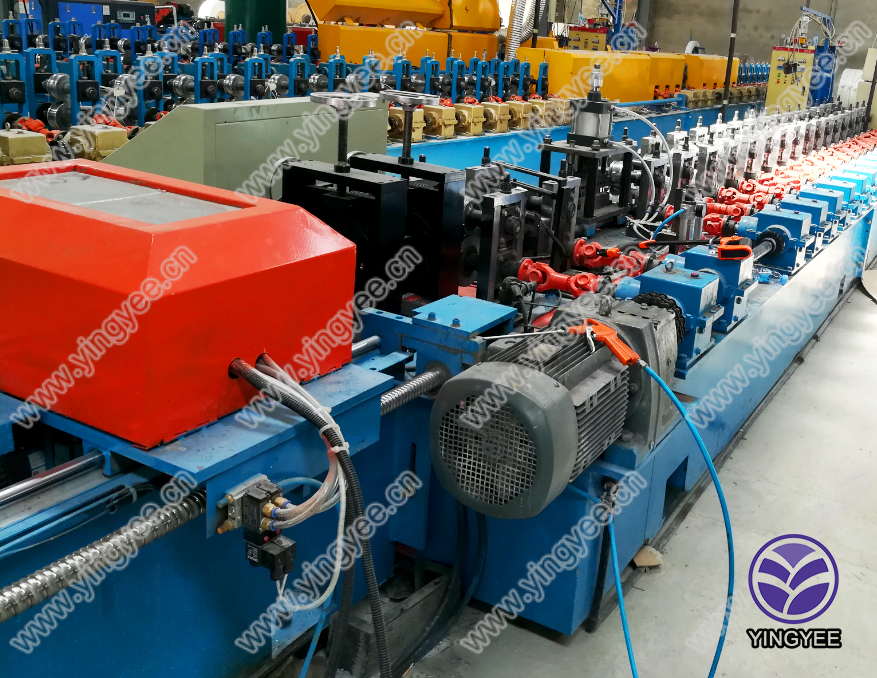

To appreciate the significance of the shelf rack upright roll forming machine, it is essential to understand roll forming technology itself. Roll forming involves the continuous bending of sheet metal into desired cross-sectional shapes. This process is particularly valuable for producing long lengths of metal parts with consistent cross-sections, which is ideal for shelf racks that require uniformity and strength.

The roll forming machine operates by feeding a coil of metal sheet through a series of rollers. Each roll is meticulously designed to bend the metal incrementally until it reaches the desired shape. This process not only ensures precision but also minimizes waste, making it a cost-effective solution for manufacturers.

Advantages of the Shelf Rack Upright Roll Forming Machine

1. Customization One of the standout features of a shelf rack upright roll forming machine is its ability to produce customized designs. Manufacturers can tailor the dimensions, thickness, and even the material type used based on their specific needs. This flexibility allows businesses to cater to unique customer requirements, whether for retail spaces, warehouses, or industrial applications.

2. Efficiency The machine's production speed is significantly higher compared to traditional manufacturing methods. Roll forming allows for continuous production, reducing the time it takes to produce a large volume of shelf racks. This efficiency helps manufacturers meet the increasing demand for storage solutions without compromising on quality.

3. Durability and Strength The shelf rack uprights produced using roll forming technology are known for their strength and durability. The process enhances the integrity of the metal by creating a continuous structure that can bear heavy loads. This makes them ideal for various storage applications, from light retail shelves to heavy-duty warehouse racking systems.

4. Reduced Waste Another major advantage is the reductions in material waste. Traditional manufacturing methods may require additional processing or cutting of materials, leading to inefficiencies. However, roll forming optimizes the use of raw materials, making it a more sustainable option. This is increasingly important in today’s environmentally conscious market.

5. Versatility The design capabilities of the shelf rack upright roll forming machine render it suitable for various applications. Beyond just standard warehouse shelving, it can be used for decorative display units, customized retail shelving, and specialized storage systems for industrial purposes. This versatility keeps manufacturers competitive in a dynamic marketplace.

Applications Across Industries

The applications of the shelf rack upright roll forming machine are far-reaching. In retail, businesses utilize these shelves for displaying products elegantly, enhancing customer experience and driving sales. Warehousing and logistics companies rely on robust racking systems that can withstand heavy inventory loads, making roll-formed racks the perfect solution.

Moreover, the construction industry benefits from these machines, as they can produce components for temporary shelving or storage solutions on job sites. With the rise of e-commerce, efficient storage systems are more critical than ever for order fulfillment and inventory management.

Conclusion

The shelf rack upright roll forming machine represents a significant advancement in the manufacturing of storage solutions. Its ability to produce customized, durable, and efficient shelving systems positions it as a game-changer in the industry. As businesses continue to seek innovative ways to maximize space and improve efficiency, the role of this machine will undoubtedly become more prominent.

Investing in a shelf rack upright roll forming machine not only reflects a commitment to high-quality production but also responds to the increasing demands of modern storage needs. As industries evolve, those who leverage advanced manufacturing technologies will be best equipped to thrive in an ever-changing marketplace.