The Art and Science of Roll Forming A Comprehensive Overview

Roll forming is a continuous bending process in which a long strip of metal is fed through a series of paired rolls to create a specific cross-sectional profile. This manufacturing technique is widely used in various industries due to its efficiency, precision, and ability to produce complex shapes from materials like steel, aluminum, and other metals. Understanding the intricacies of roll forming can provide valuable insights into its applications and advantages in modern manufacturing.

The Roll Forming Process

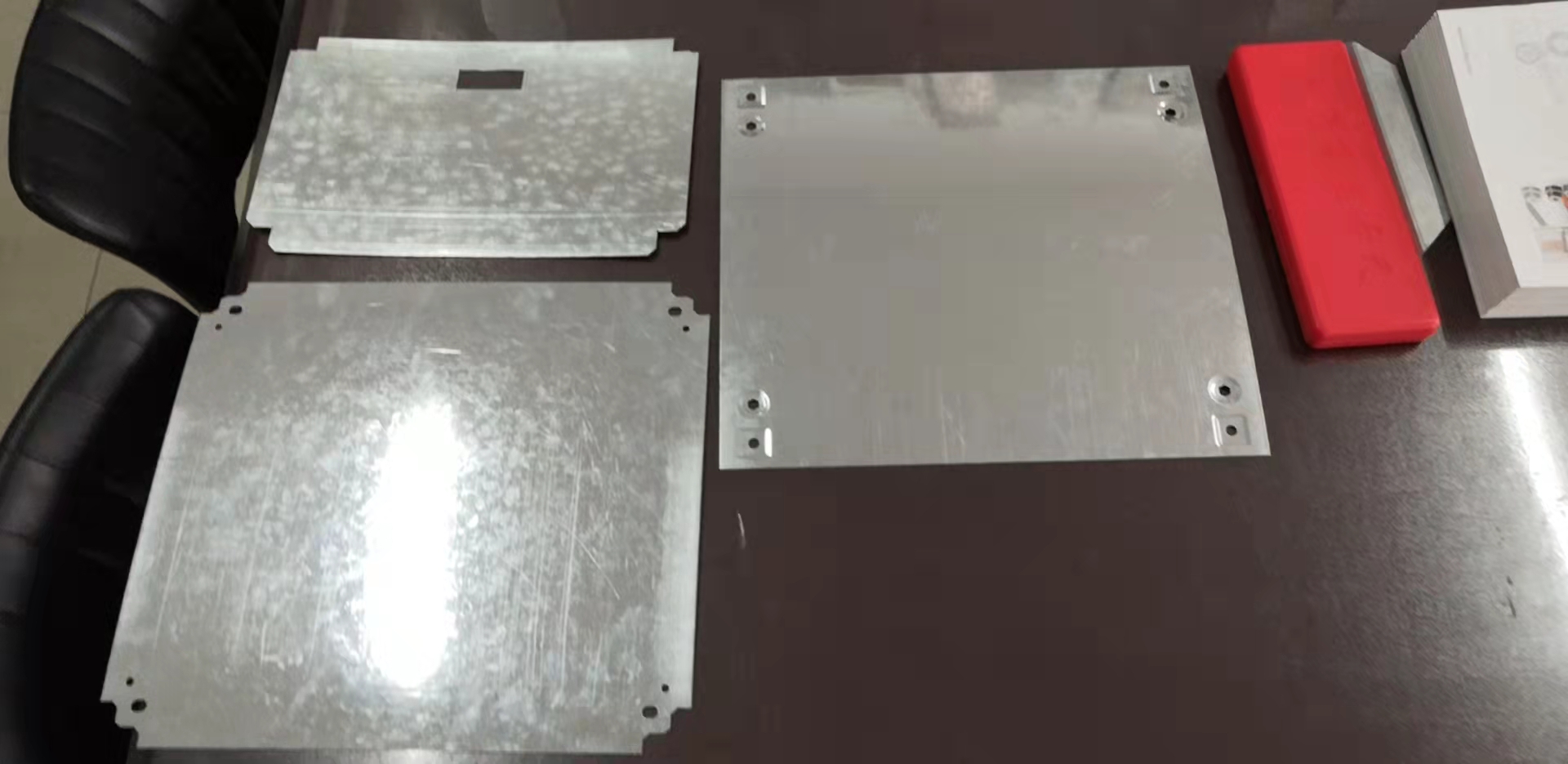

The roll forming process begins with a flat piece of metal, typically in coil form. As this metal is fed into the roll forming machine, it passes through multiple sets of rollers, each designed to progressively bend the metal into the desired shape. The design of these rollers is crucial; they need to be precisely engineered to ensure that the metal is shaped uniformly and without defects. The rolls can be made from a variety of materials, but they must be strong enough to withstand the forces exerted during the bending process.

One of the key factors in successful roll forming is the setup of the machine. Adjustments to the roll spacing and angles, as well as the speed of the process, can significantly influence the quality of the finished product. Operators must have a thorough understanding of the material properties and the design of the profile to make necessary adjustments. Computer-aided design (CAD) and finite element analysis (FEA) software are often employed to optimize this setup, resulting in improved efficiency and reduced waste.

Advantages of Roll Forming

One of the most significant advantages of roll forming is its ability to produce long lengths of metal shapes with consistent quality and precision. Unlike other metal shaping methods, such as stamping, which require multiple operations, roll forming allows manufacturers to create complex profiles in a single pass. This not only speeds up the production process but also minimizes material waste—a critical consideration in today’s eco-conscious manufacturing environment.

Furthermore, roll forming is highly versatile

. The process can accommodate a wide range of materials and thicknesses, which makes it suitable for producing a broad spectrum of products, from simple angles and channels to intricate profiles used in automotive, construction, and aerospace applications.

Another advantage is the repeatability of the process. Once a roll forming line is set up for a particular profile, it can produce thousands of identical parts without sacrificing quality. This is particularly beneficial for industries that require large volumes of consistent components, such as the construction sector for framing and roofing applications.

Applications of Roll Forming

Roll forming is utilized in numerous industries, showcasing its versatility and efficiency. In the construction industry, it is widely used for producing roof panels, wall panels, and metal studs. The automotive sector also leverages roll forming for structural components such as bumpers, support brackets, and chassis, taking advantage of the strength and lightweight properties of formed metal.

Additionally, the appliance industry employs roll forming to create parts for ovens, refrigerators, and washing machines, benefiting from its ability to produce custom shapes tailored to specific designs. With the ongoing trend towards lightweight and sustainable materials, roll forming is becoming increasingly popular for manufacturing components from advanced materials like high-strength steel and aluminum alloys.

The Future of Roll Forming

As technology advances, the roll forming process is expected to evolve as well. Innovations such as automation and advanced monitoring systems are being integrated into roll forming lines to enhance efficiency and reduce errors. The implementation of Industry 4.0 principles—smart manufacturing that utilizes interconnected systems and data analytics—is paving the way for more intelligent roll forming solutions.

In conclusion, roll forming is a sophisticated manufacturing method that combines art and science to produce high-quality metal components with remarkable efficiency. Through continuous innovation and adaptation, this technique is poised to remain a crucial player in the future of manufacturing, meeting the growing demands of various industries while promoting sustainability and resource efficiency. As manufacturers increasingly recognize the potential of roll forming, it will undoubtedly cement its place as a cornerstone of modern metalworking.