Understanding the Roller Shutter Door Forming Machine

In the realm of industrial manufacturing, efficiency and precision are paramount, and one of the machines that epitomizes these values is the roller shutter door forming machine. This sophisticated equipment is designed to produce high-quality roller shutter doors, which are widely used for security and aesthetic purposes in commercial and residential buildings. This article explores the functionality, advantages, and key features of a roller shutter door forming machine.

Functionality of the Machine

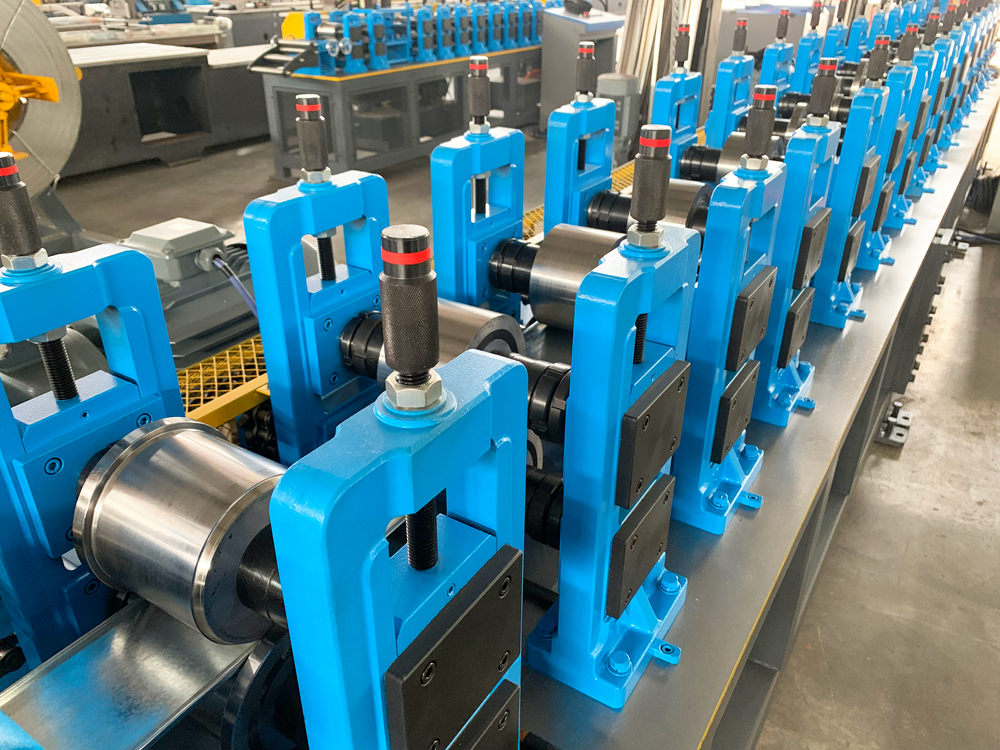

The primary purpose of the roller shutter door forming machine is to transform raw materials, typically galvanized steel or aluminum, into durable roller shutter doors. The process begins with feeding the metal sheets into the machine. The machine then utilizes a series of rollers and dies to shape the metal into the desired profile. Most models are equipped with a leveling system to ensure uniformity and precision throughout the production cycle.

After the shaping process, the formed strips are often cut to the required lengths using an integrated cutting mechanism, ensuring minimal waste. Depending on the specifications of the project, additional features such as perforation for ventilation and openings for locks may also be incorporated at this stage. Finally, the finished doors are ready for assembly and installation, providing security and convenience to end-users.

Advantages of Roller Shutter Door Forming Machines

1. Efficiency The automation of the forming process significantly reduces the time and labor required to produce roller shutter doors. High-speed machines can create large quantities in a fraction of the time it would take through manual methods.

2. Quality Control Modern roller shutter door forming machines come with advanced technology that ensures consistent quality. Precision engineering means that every door is made to exact specifications, reducing the likelihood of defects and ensuring high standards.

3. Cost-Effectiveness While the initial investment in a forming machine may be substantial, the increase in production efficiency and reduction in labor costs lead to significant savings in the long run. Additionally, the material waste is minimized, contributing to cost efficiency.

4. Versatility Many roller shutter door forming machines can be easily adjusted to create different door profiles and sizes. This flexibility allows manufacturers to cater to a wide range of customer needs without investing in multiple pieces of equipment.

Key Features to Consider

When investing in a roller shutter door forming machine, several key features should be considered

- Roller Design The quality of rollers affects the forming process. Higher-quality rollers provide better shaping and reduce maintenance needs.

- Cutting Mechanism A reliable integrated cutting system is essential for ensuring precise lengths without wasting material.

- Control System Advanced programmable logic controllers (PLCs) allow for easy operation and setup, facilitating quick adjustments for different door specifications.

- Safety Features Since forming machines operate heavy materials and sharp components, built-in safety features are crucial to protect operators from potential injuries.

- After-Sales Support Consider the availability of technical support and spare parts. A reliable manufacturer should offer comprehensive service to ensure the machine runs smoothly over years of operation.

Conclusion

The roller shutter door forming machine is a valuable asset for any manufacturer looking to streamline their production of roller shutter doors. With advantages such as enhanced efficiency, quality control, and cost-effectiveness, these machines enable businesses to meet market demands effectively. Investing in advanced technology will not only improve production capacity but also pave the way for future growth in the competitive construction and manufacturing industries.