The Rise of PU Sandwich Panel Machine Factories A Game Changer in Construction Materials

In the ever-evolving world of construction, innovation has become a cornerstone of efficiency and sustainability. At the forefront of this revolution is the PU sandwich panel machine factory, a specialized facility dedicated to the production of polyurethane (PU) sandwich panels. These panels are engineered to provide superior insulation, lightweight construction, and durability, making them an indispensable component of modern architecture.

Understanding PU Sandwich Panels

PU sandwich panels consist of two outer layers, typically made of metal or other sturdy materials, with a core of polyurethane foam sandwiched between them. This design not only enhances the structural integrity of the panels but also provides excellent thermal insulation properties. As energy efficiency becomes increasingly important in building design, PU sandwich panels are gaining popularity for both residential and commercial projects.

The advantages of PU sandwich panels are numerous. They offer lightweight solutions that simplify transportation and reduce labor costs. Additionally, the manufacturing process ensures that the panels are uniform in quality, providing consistent performance across various applications. Whether used in the construction of warehouses, cold storage facilities, or residential buildings, PU sandwich panels deliver superior performance that meets the demands of contemporary construction.

The Role of PU Sandwich Panel Machine Factories

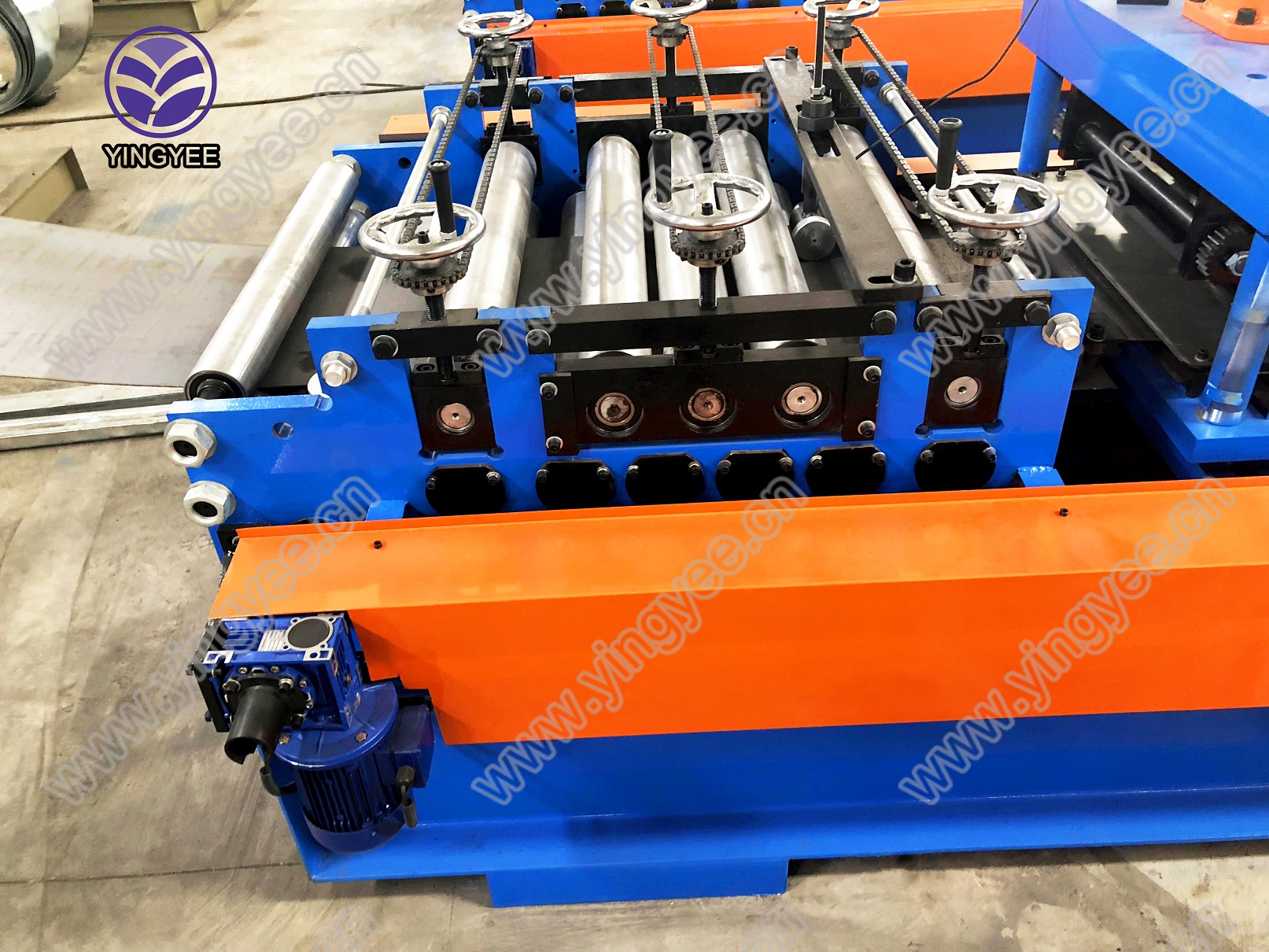

PU sandwich panel machine factories play a crucial role in the production chain of these innovative building materials. These factories are equipped with advanced machinery that automates the manufacturing process, ensuring efficiency and precision. The production line typically includes a series of machines responsible for various stages such as foaming, cutting, and laminating.

The foaming machine, for instance, injects polyurethane into the cavity between the outer layers under controlled conditions, allowing for uniform density and minimizing waste. Following this, the panels are cut to specified dimensions and laminated to enhance their stability. The entire process is designed to maximize output while maintaining high quality standards, which is essential in meeting the growing demand for PU sandwich panels in the construction industry.

Benefits for Manufacturers and Builders

For manufacturers, investing in a PU sandwich panel machine factory can yield significant benefits. With the demand for eco-friendly and energy-efficient building materials on the rise, factories that produce PU sandwich panels are well-positioned to capitalize on this trend. The ability to produce high-quality panels in bulk not only increases profitability but also enhances market competitiveness.

For builders and contractors, utilizing PU sandwich panels can streamline construction projects. The speed of installation is greatly reduced compared to traditional materials, allowing for faster project completion and reduced labor costs. The panels’ insulation properties also contribute to long-term energy savings for building owners, which makes them an attractive choice for sustainable construction.

Sustainability and Future Prospects

As sustainability becomes a focal point in construction practices, PU sandwich panels offer an eco-friendly alternative to traditional building materials. The insulation properties of PU panels reduce the energy required for heating and cooling, leading to lower carbon emissions over the life cycle of a building. Additionally, many factories are adopting environmentally responsible production methods and materials, further minimizing their ecological footprint.

Looking ahead, the future of PU sandwich panel machine factories appears bright. The ongoing advancements in technology are likely to lead to even more efficient manufacturing processes, enabling factories to produce panels that meet stricter energy regulations and performance standards. As global trends shift towards greener building practices, the demand for PU sandwich panels will continue to grow, fostering innovation and expansion within the industry.

Conclusion

In conclusion, PU sandwich panel machine factories represent a significant advancement in the construction materials sector. With their ability to produce high-quality, energy-efficient panels, these factories are not only transforming building practices but also contributing to a more sustainable future. As the construction industry embraces innovation, the role of PU sandwich panels is set to become even more vital in creating structures that are both functional and environmentally friendly. This growth trajectory not only promises economic benefits for manufacturers and builders alike but also supports the broader goal of sustainable development globally.