The Importance of Purlin, Metal Stud, and Track Machines in Modern Construction

In the realm of modern construction, efficiency and precision are paramount. The emergence of specialized machinery has transformed the way structures are built, enabling faster project completion times and enhanced structural integrity. Among the essential equipment in this domain are purlin, metal stud, and track machines, which play a crucial role in fabricating components that are foundational to building frameworks.

Understanding Purlins, Metal Studs, and Tracks

Before delving into the machinery that produces these materials, it is important to understand their functions. Purlins are horizontal structural members used to support roofing and are typically made of steel or aluminum. They provide necessary support for the roof and can carry loads from the roof material down to the building's main framework.

Metal studs serve as the upright support framework within walls, allowing for easy installation of drywall, insulation, and electrical systems. Their light weight and strength make them a preferred choice over traditional wooden studs, especially in commercial and industrial applications.

Tracks complement metal studs by providing a structural grounding for them. These tracks are fixed to the floor and ceiling, establishing a secure boundary within which the metal studs are installed. The combination of studs and tracks forms a resilient framework that can withstand various pressures, making them integral to modern building designs.

The Role of Machinery

Purlin, metal stud, and track machines are designed to automate the production of these critical components

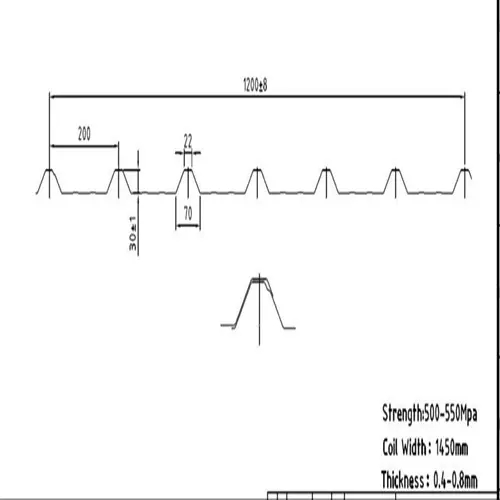

. By utilizing advanced technology, such as computer numerical control (CNC) systems and high-speed rollers, these machines can produce components with remarkable precision and speed.1. Purlin Machines These machines are engineered for manufacturing purlins from roll-form steel. The process typically involves uncoiling the steel, feeding it through a series of rollers that shape it into the desired profile, and then cutting it to length. The automation in purlin production reduces labor costs and minimizes material waste, which is a significant advantage in large-scale projects.

2. Metal Stud Machines Similar to purlin machines, metal stud machines utilize a roll-forming technique to create studs. The process includes feeding a steel coil through rollers that shape it into a C or U-profile, depending on the design requirements. These machines also incorporate punching and cutting stations to prepare the studs for assembly, ensuring they are ready for immediate installation.

3. Track Machines Track machines work in tandem with metal stud machines to create the channel components that fit along the top and bottom of wall assemblies. This machinery operates under principles similar to those used in stud production but is tailored to create a distinct profile. By integrating both metal stud and track production, manufacturers can streamline the supply chain, providing contractors with pre-cut and pre-punched materials that maximize efficiency on job sites.

Benefits of Advanced Machinery

The integration of purlin, metal stud, and track machines into construction processes has yielded numerous benefits

- Increased Production Speed Automated machinery allows for faster production cycles, enabling suppliers to meet the demands of large-scale projects without compromising quality.

- Reduced Labor Costs With machinery handling much of the fabrication, the need for a large workforce decreases, allowing for significant savings in labor costs.

- Enhanced Precision and Quality These machines offer consistent quality that manual processes can seldom achieve. The precise dimensions lead to improved fit and finish, reducing the likelihood of errors during installation.

- Sustainability With less waste generated during production and the ability to use recyclable materials, these machines contribute to more eco-friendly construction practices.

Conclusion

As the construction industry continues to evolve, the importance of purlin, metal stud, and track machines cannot be overstated. They are pivotal in setting frameworks for modern buildings, supporting both structural integrity and design flexibility. The shift towards automation and precision in manufacturing these components represents a significant leap forward in construction technology, promising enhanced productivity and sustainability for future projects. As we look ahead, the continued development of such machinery will undoubtedly play a central role in shaping the built environment.