The Portable Roll Former Revolutionizing Metal Fabrication

In the realm of metal fabrication, efficiency and versatility are paramount. Enter the portable roll former, a game-changing tool that has transformed the way metal sheets are processed. Compact, easy to operate, and capable of producing a variety of profiles, the portable roll former has become an essential asset for contractors and manufacturers alike.

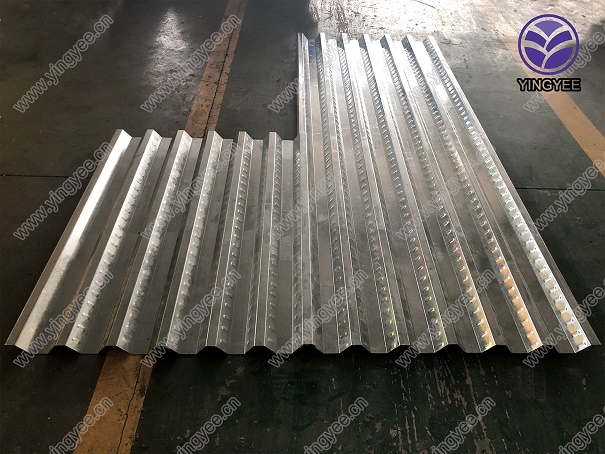

A portable roll former is designed to create metal sections with precision. It utilizes a series of rollers to bend and shape metal strips into desired profiles, such as roofing panels, wall panels, and various other metal components. What sets portable roll formers apart from traditional stationary models is their mobility. These machines can be easily transported to job sites, allowing for on-demand metal forming without the need for extensive handling or transportation of materials.

One of the most significant advantages of portable roll formers is their ability to minimize waste. Traditional metal fabrication often involves cutting large sheets of metal into smaller pieces, leading to significant scrap. In contrast, portable roll formers can produce sections directly on-site, optimizing material usage and reducing costs. This efficiency is critical in today's competitive market, where every penny counts.

Moreover, these machines are designed for user-friendly operation. Many models come with intuitive controls that allow even those with minimal experience in metalworking to produce high-quality results. With the ability to adjust the machine for different profiles and thicknesses, contractors can easily switch between projects while ensuring consistent quality.

The versatility of portable roll formers extends beyond just roofing or siding. They can also create custom profiles for specialized projects, allowing companies to cater to unique design requirements. This adaptability opens up a new world of possibilities for architects and builders, who can now implement innovative designs without worrying about high upfront costs or logistical challenges.

In recent years, advancements in technology have further enhanced the capabilities of portable roll formers. Many modern machines now feature integrated digital controls and software that allow for precise adjustments and data tracking. These innovations help ensure that even complex profiles can be manufactured accurately and efficiently.

In conclusion, the portable roll former has revolutionized the metal fabrication industry by providing contractors with a versatile, efficient, and cost-effective solution for on-site metal processing. As demand for customized metal solutions continues to grow, portable roll formers will undoubtedly play a crucial role in shaping the future of construction and manufacturing. By reducing waste, enhancing mobility, and providing the ability to create intricate designs on demand, these machines have established themselves as indispensable tools in the modern metalworking landscape.