The Evolution and Significance of Pipe Making Machines

In the world of manufacturing, efficiency and precision are paramount. Among the many machines that have revolutionized various industries, the pipe making machine stands out as a vital component in producing pipes used across numerous applications, including construction, plumbing, and the oil and gas sectors. This article explores the significance of pipe making machines, their evolution, and the advancements that have reshaped production techniques.

The Evolution and Significance of Pipe Making Machines

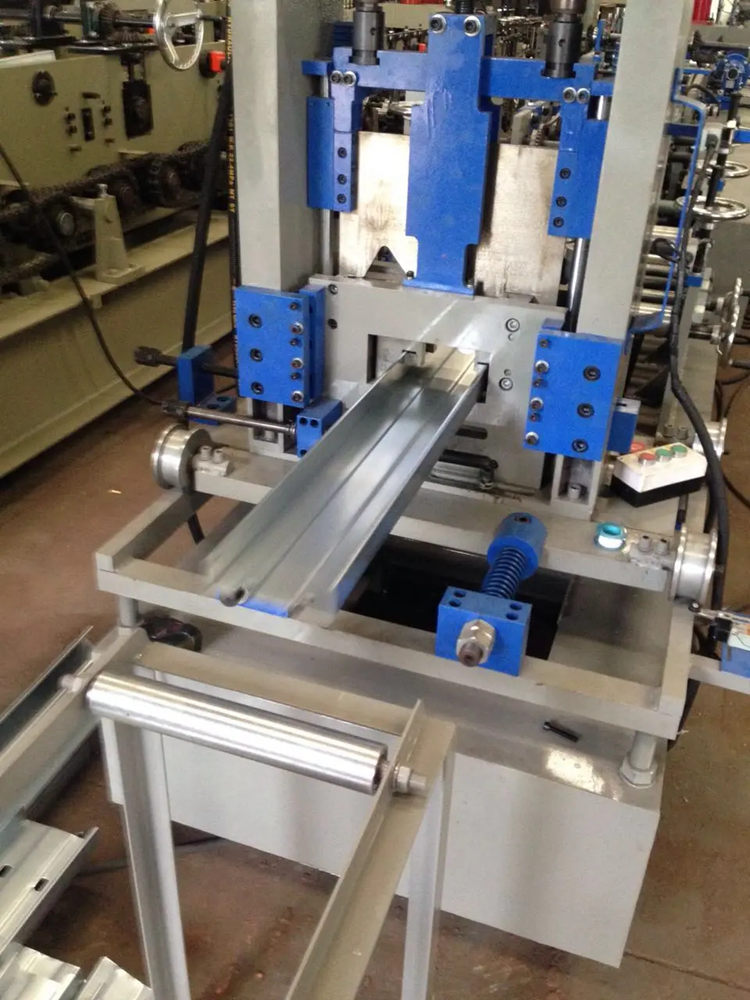

Modern pipe making machines utilize advanced technology to automate and enhance the manufacturing process. These machines can produce pipes of various materials, including PVC, metal, and composite materials, efficiently and with high accuracy. The automation of the process not only increases production rates but also reduces labor costs and minimizes human error, ensuring consistent quality across every pipe produced.

One notable advancement in pipe making technology is the introduction of the extrusion process. In this method, raw materials are melted and forced through a die, resulting in continuous lengths of pipe. This process can be precisely controlled, allowing manufacturers to produce pipes with specific diameters and wall thicknesses, tailored to meet the varying demands of different applications.

Furthermore, pipe making machines are now equipped with advanced monitoring systems and technology such as IoT (Internet of Things) integrations. These features enable real-time data collection and analysis, allowing manufacturers to monitor production efficiency, machine health, and pipe quality. Early detection of any issues can lead to timely interventions, minimizing downtime and optimizing operations.

The importance of pipe making machines extends beyond manufacturing efficiency. They play a crucial role in ensuring the availability of essential infrastructure. From supplying water to homes and businesses to facilitating the efficient transport of oil and gas, the reliability of pipes is paramount. As the demand for sustainable materials grows, modern pipe making machines are also adapting to produce eco-friendly options, contributing to a more sustainable future.

In conclusion, pipe making machines are indispensable in today's manufacturing landscape. Their evolution from manual production to automated precision machines reflects the broader advancements in technology and industry practices. As we continue to innovate, these machines will not only enhance efficiency but also ensure that we meet the ever-growing needs of society for reliable and durable piping solutions.