The Nuts and Bolts of Large Span Roll Forming Machines with Bending Capabilities

In modern manufacturing, efficiency and precision stand at the forefront of production innovations. Among the critical machinery that enables these qualities in metalworking is the large span roll forming machine, particularly those designed to integrate bending capabilities. This article explores the significance, operation, and advantages of such machines in the industrial landscape.

Understanding Roll Forming Machines

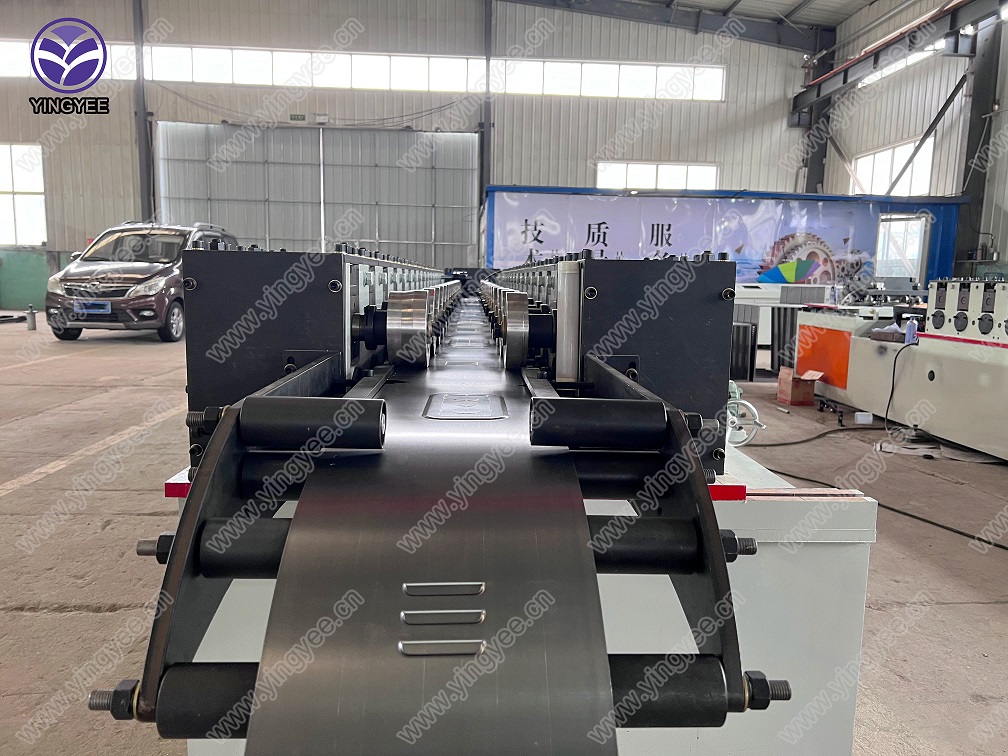

Roll forming is a continuous bending operation in which a long strip of metal, usually coiled steel, is passed through consecutive pairs of rolls. Each pair of rolls progressively shapes the metal into the desired profile. Large span roll forming machines are particularly designed to handle larger producing widths and more complicated profiles. These machines align and guide metal sheets meticulously to ensure uniform bends and cuts, reducing material wastage and increasing efficiency.

Integration of Bending Machines

While traditional roll forming machines are adept at producing consistent profiles, integrating a bending machine expands their capabilities significantly. A bending machine allows for the creation of complex, three-dimensional shapes, such as frames or structural components that are otherwise challenging to achieve with standard roll forming alone. The synergy of these two machines allows manufacturers to produce finished components in a single workflow, thus optimizing time and resources.

Advantages of Large Span Roll Forming Machines with Bending Functions

1. Increased Production Efficiency The combination of roll forming and bending in one machine eliminates the need for multiple setups, thereby speeding up the overall process. This integration leads to reduced lead times and higher output without compromising quality.

2. Cost-Effective Operations By reducing the number of machines required and streamlining the production process, manufacturers can save on operational costs. Additionally, the waste generated is minimized, which further lowers material expenses.

3. Versatility in Production These advanced machines can produce a wide range of profiles and shapes suitable for various applications, from construction elements, automotive parts to sophisticated industrial components. This versatility allows manufacturers to adapt quickly to changing market demands without investing in new machinery.

4. Precision and Quality Control Advanced technology equipped in these machines, such as automated measurements and CNC integration, ensures high precision in the produced parts. Quality control processes can be built-in, providing consistency and reducing the likelihood of defects.

5. Sustainability With the ability to produce components more efficiently and with less waste, these machines support sustainable manufacturing practices. Efficient use of materials translates to a lower environmental footprint, which is increasingly important in today’s manufacturing industries.

Conclusion

The evolution of manufacturing technologies has led to significant advancements, particularly in the realm of large span roll forming machines combined with bending capabilities. These machines not only enhance production efficiency and versatility but also provide cost-effective solutions and foster sustainability in manufacturing. As industries continue to evolve and demand higher standards of both quality and efficiency, the role of these sophisticated machines will undoubtedly become even more significant, ensuring that manufacturers remain competitive and responsive to global market needs.