Overview of MS Tube Mill Technology

The MS tube mill, an abbreviation for Mild Steel tube mill, is a specialized machinery system used in the manufacturing of steel tubes and pipes. With its ability to process raw materials into finished products efficiently, its significance in various industries, including construction, automotive, and infrastructure, cannot be overstated. This article takes a closer look at the operating principles, advantages, and applications of MS tube mills.

Working Principle

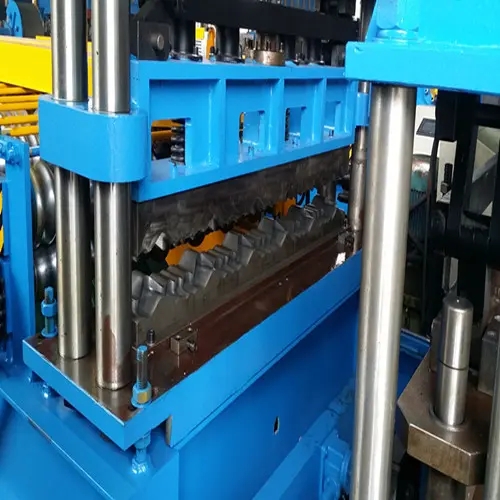

The MS tube mill operates on a continuous production basis, wherein flat steel strips are fed into the machine, passing through a series of rollers and forming dies. These components shape the strip into a tubular form. Once the tube is formed, welding is applied longitudinally to join the edges, creating a seamless looking tube. The welding process typically involves high-frequency induction welding or TIG (Tungsten Inert Gas) processes, depending on the specific requirements and specifications of the end product.

After the welding step, the tube undergoes various finishing processes such as cooling, cutting, and inspection. The cooling phase is critical as it ensures that the weld area is correctly treated, maintaining the integrity and strength of the tube. The final product can be produced in various diameters and thicknesses, meeting diverse customer needs.

Advantages of MS Tube Mills

One of the key advantages of MS tube mills is their versatility. These mills can produce a wide range of tube sizes and shapes with substantial ease. Additionally, the quality of the products is generally high, as modern tube mills are equipped with precision engineering and advanced technology. This results in tubes with consistent dimensions, smooth surfaces, and superior mechanical properties.

Furthermore, MS tube mills are designed for efficiency. They are capable of high-speed production without compromising quality. This rapid output reduces overall production costs and helps businesses meet increasing demands quickly. The automation of many processes also minimizes labor costs, making it a cost-effective solution for manufacturers.

Applications of MS Tube Mills

MS tube mills find applications in numerous industries. In construction, they are indispensable for fabricating structural components like columns, beams, and reinforcements. The automotive industry utilizes these tubes in manufacturing frames, exhaust systems, and various structural applications. Additionally, the oil and gas sector relies on MS tube mills for producing pipes utilized in the transportation of hydrocarbons.

Moreover, sectors such as furniture and appliance manufacturing utilize mild steel tubes for creating sturdy, reliable products. Industries focused on electrical use these tubes for conduits and wiring applications due to their excellent conductive properties.

Conclusion

In summary, MS tube mills represent a crucial technology in the modern manufacturing landscape. Their ability to produce high-quality steel tubes efficiently and in various sizes makes them integral to numerous industries. As technology continues to advance, we can expect further improvements in the capabilities and efficiencies of MS tube mills, ensuring their relevance in the years to come. The ongoing demand for steel tubes across various sectors underscores the importance of this technology in supporting infrastructure development and industrial growth.