The Metal Stud Machine Revolutionizing Construction and Manufacturing

In the ever-evolving landscape of construction and manufacturing, the metal stud machine has emerged as a game-changer, streamlining processes and enhancing efficiency. This innovative piece of equipment is designed to produce metal studs—essential components in modern building frameworks and interior partitions. Its rise in popularity stems from the numerous benefits it offers, ranging from precision fabrication to significant cost savings.

Metal studs are widely favored over traditional wooden framing because they are more durable, resistant to pests, and less likely to warp or twist. Furthermore, they are made from recycled materials, making them a more environmentally friendly option. As the demand for sustainable construction practices grows, the metal stud machine plays a crucial role in facilitating this shift. By automating the production of metal studs, these machines not only ensure a consistent quality of materials but also reduce the time required to prepare for construction projects.

One of the main advantages of the metal stud machine is its capacity for high-speed production. These machines can quickly cut, shape, and assemble metal studs with incredible accuracy, significantly expediting the construction timeline. This speed is particularly beneficial for large scale projects, where time is of the essence, and delays can lead to increased costs. Additionally, the precision offered by metal stud machines minimizes waste material, which not only saves money but also aligns with sustainable construction goals.

Moreover, the versatility of the metal stud machine cannot be overlooked. These machines can be adapted to produce various sizes and types of studs, allowing manufacturers to cater to diverse construction needs. Whether it’s for residential building, commercial spaces, or industrial settings, the metal stud machine can produce tailored solutions efficiently. This adaptability is crucial in a marketplace that demands customization and flexibility.

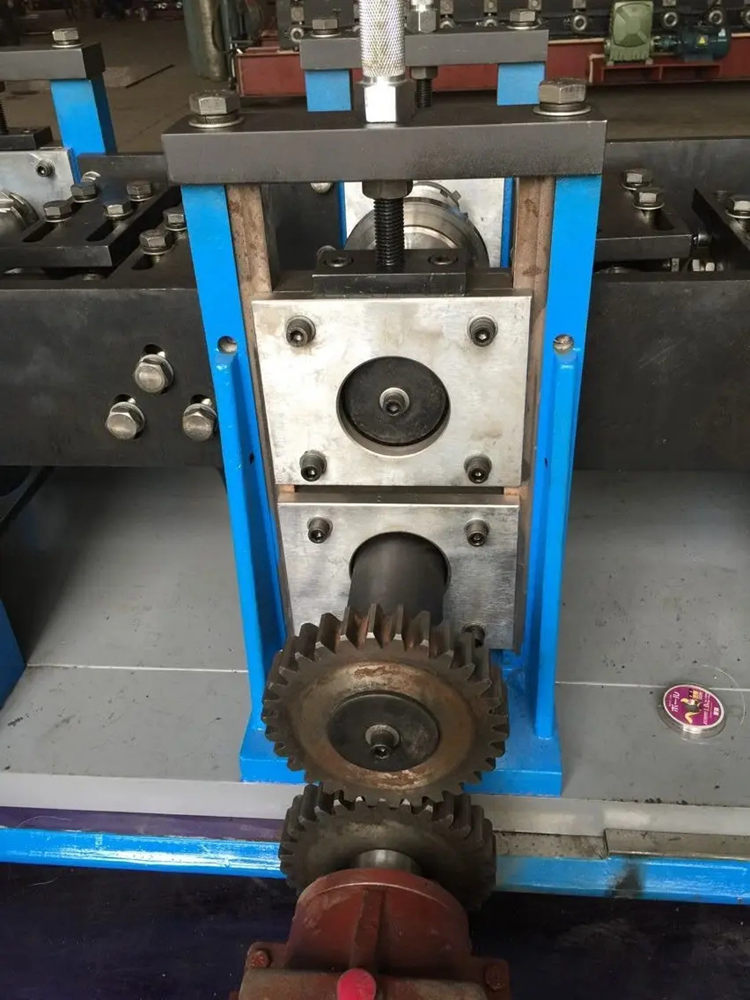

The integration of advanced technology into metal stud machines further enhances their performance and user-friendliness. Many of these machines come equipped with computerized controls that allow for easy adjustments and programming, enabling operators to produce intricate designs with minimal effort. Additionally, advancements in automation technology have led to the development of machines that can function with little human intervention, reducing labor costs and mitigating the risk of human error.

Training and safety are important considerations when operating metal stud machines. Manufacturers often provide comprehensive training programs for operators to ensure they understand how to use the machines effectively and safely. Adhering to safety protocols is paramount, as the machinery can be powerful and complex. By prioritizing training and safety, companies can foster a more efficient and secure workplace.

In conclusion, the metal stud machine is at the forefront of modern construction technology. Its ability to produce high-quality, sustainable materials quickly and efficiently not only addresses the demands of contemporary building projects but also contributes to broader environmental goals. As the construction industry continues to evolve, the importance of such machines in enhancing productivity and sustainability cannot be understated. As we look to the future, the metal stud machine will undoubtedly remain a vital component in the toolbox of innovative construction practices.