The Evolution and Importance of Metal Standing Seam Roll Forming Machines

In the rapidly advancing world of manufacturing, efficiency and precision are paramount. One of the technologies that have gained significant traction in recent years is the metal standing seam roll forming machine. This innovative machinery is instrumental in producing high-quality standing seam panels, which have become a popular choice in roofing and wall applications.

Understanding Standing Seam Panels

Standing seam panels are characterized by their interlocking seams that rise above the level of the roofing or wall surface. This design not only enhances aesthetics but also provides superior weather resistance and durability. Commonly used in both commercial and residential structures, these panels can withstand various weather conditions, making them a reliable choice for builders and architects alike.

Functionality of Roll Forming Machines

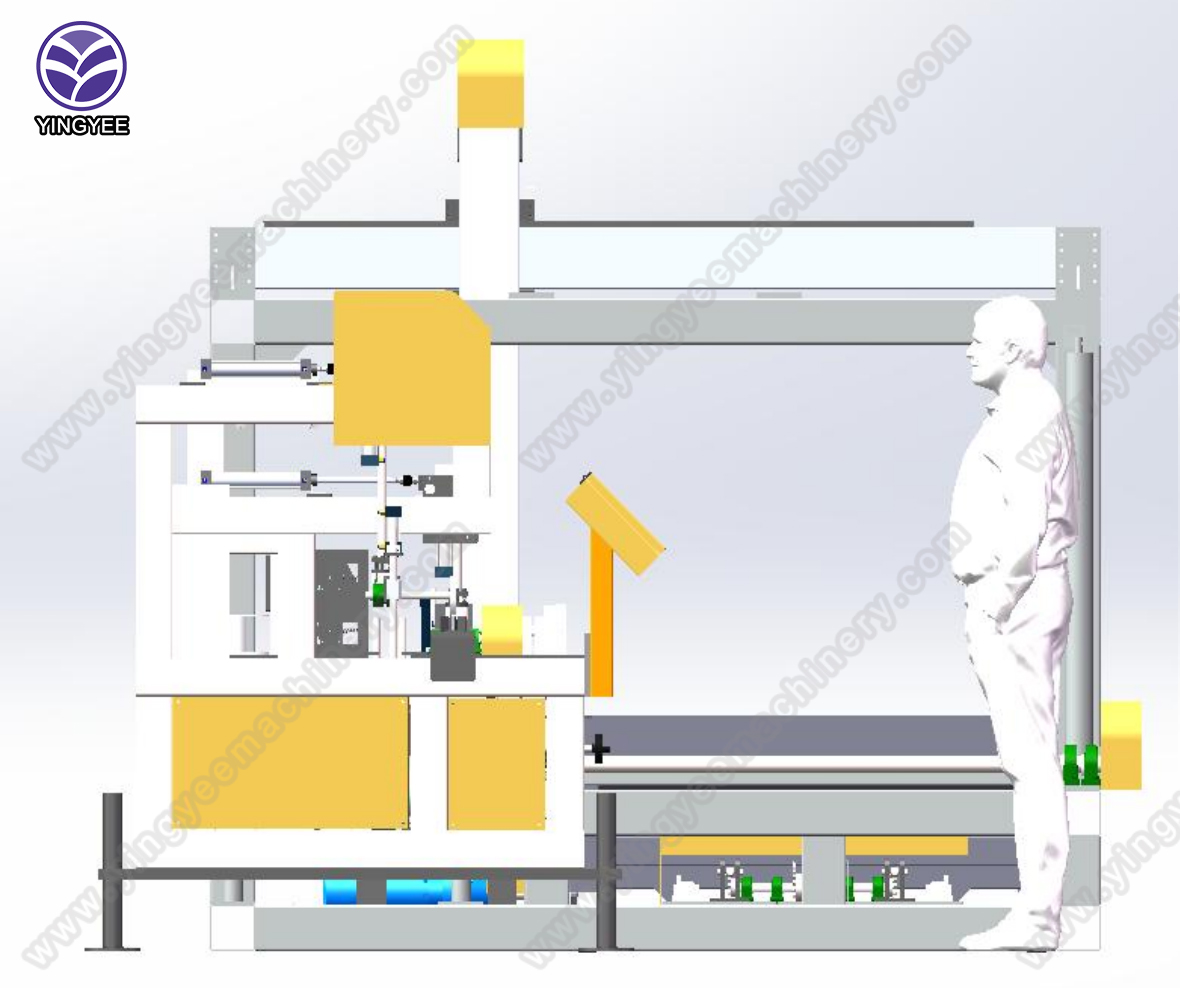

A metal standing seam roll forming machine operates through a continuous process that transforms metal coils into finished standing seam panels. The machine comprises various rollers that shape the metal as it moves through the system. This process involves several stages, including decoiling, cold forming, and cutting to length. The precision of these machines ensures that each panel produced meets stringent quality standards.

Roll forming machines are equipped with advanced automation systems that enhance their efficiency. These systems can automatically adjust settings based on the specifications required for different projects. This flexibility allows manufacturers to cater to a diverse range of customer needs without compromising on quality or speed.

Advantages of Using Standing Seam Roll Forming Machines

The adoption of metal standing seam roll forming machines comes with a myriad of benefits

. Firstly, the production speed is significantly higher compared to traditional methods. Manufacturers can produce large quantities of panels in a fraction of the time, which is crucial in meeting tight deadlines.Moreover, the precision of roll forming technology reduces material wastage. Because the panels are produced to exact specifications, the need for additional trimming and adjustments is minimized. This not only conserves resources but also translates to cost savings for manufacturers.

Additionally, the durability of the panels produced by these machines is exceptional. Standing seam panels are often made from materials such as galvanized steel, aluminum, or copper, all of which offer longevity and resistance to corrosion. This makes them an ideal choice for various applications, ranging from residential homes to large commercial facilities.

Market Trends and Future Outlook

As sustainability becomes increasingly important in the construction industry, the demand for energy-efficient and environmentally friendly building materials has surged. Standing seam roofs, due to their ability to facilitate energy-efficient installations like solar panels, are gaining popularity. This trend is expected to drive further innovation in roll forming technology.

Manufacturers are continually seeking ways to improve their machines. The integration of smart technology, including IoT (Internet of Things) capabilities, enables real-time monitoring and adjustments, enhancing overall efficiency and reducing downtime. These advancements suggest a bright future for metal standing seam roll forming machines.

Conclusion

The metal standing seam roll forming machine represents a significant leap in manufacturing technology, providing a perfect blend of efficiency, precision, and durability. As the construction industry evolves, the demand for innovative solutions will only increase, solidifying the role of these machines as essential tools in modern manufacturing. Whether for residential roofs or expansive commercial structures, standing seam panels produced by these machines will continue to play a vital role in enhancing the architectural landscape.