The Metal Sound Barrier Cold Bending Machine Revolutionizing Modern Construction

In the world of construction and structural engineering, the quest for innovative tools that enhance productivity and efficiency is never-ending. One such advancement is the Metal Sound Barrier Cold Bending Machine—a sophisticated piece of equipment designed to fabricate sound barriers using cold bending techniques. This technology has gained traction due to its ability to produce high-quality components while maintaining aesthetic value and structural integrity.

Understanding Cold Bending

Cold bending refers to the process of shaping metal into specific configurations without the application of heat. This technique is particularly advantageous for creating sound barriers, as it preserves the material's properties and ensures long-lasting durability. The cold bending process typically involves applying significant pressure to the metal sheet or profile, which allows it to be formed into desired shapes with precision.

The Importance of Sound Barriers

Sound barriers play a critical role in mitigating noise pollution, especially in urban areas and near highways, railroads, or industrial facilities. The incessant noise from traffic or machinery can adversely affect the quality of life, leading to health issues and decreased property values. Metal sound barriers are favored for their durability, low maintenance, and effectiveness in reducing noise levels.

Features of the Metal Sound Barrier Cold Bending Machine

The Metal Sound Barrier Cold Bending Machine comes equipped with various features that enhance its functionality

1. Precision Engineering These machines are designed with advanced controls and measurement systems that ensure precise bending angles and lengths. This accuracy is essential when creating components that fit seamlessly into larger structures.

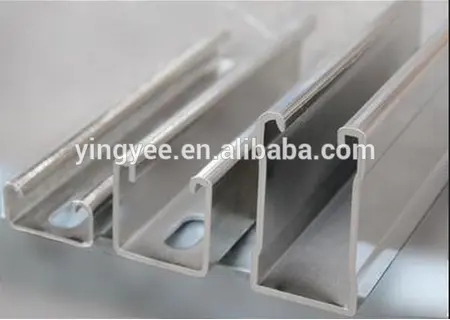

2. Versatile Material Compatibility Whether using aluminum, steel, or stainless steel, the machine can accommodate a variety of metal types and thicknesses, making it versatile for different projects.

3. High Efficiency and Speed Modern machines are built to maximize productivity, allowing for faster processing of materials. This efficiency not only reduces labor costs but also accelerates project timelines.

4. User-Friendly Interface Many machines feature digital controls and intuitive interfaces, allowing operators to program complex bending tasks with ease.

5. Enhanced Safety Features Safety is paramount in construction environments. Cold bending machines are equipped with safety mechanisms to protect operators from potential hazards during the bending process.

Applications in Construction

The applications of the Metal Sound Barrier Cold Bending Machine extend beyond merely creating sound barriers. They can also be employed to manufacture various architectural elements, such as decorative metal facades, railings, and frames. Additionally, the machine’s capabilities allow for the production of custom designs, accommodating specific project requirements or client preferences.

Environmental Benefits

In an era where sustainability is paramount, cold bending technology presents several environmental advantages. The process generates less waste compared to traditional bending techniques that require heating, thus promoting a more sustainable approach to metal fabrication. Furthermore, sound barriers made from metal can be recycled at the end of their lifespan, aligning with green building initiatives.

Conclusion

The Metal Sound Barrier Cold Bending Machine represents a significant leap forward in construction technology. By combining precision engineering with efficiency and sustainability, these machines are revolutionizing how sound barriers are produced. As urbanization continues to rise and the demand for effective noise control solutions grows, the role of this innovative equipment will undoubtedly expand, paving the way for quieter, more livable environments. The future of construction looks promising with such technological advancements facilitating the design and installation of functional, aesthetically pleasing structures.