For those in the construction industry, the term large span forming machine often signals innovation and efficiency in structural project execution. These machines are revolutionizing the way large spans are constructed, offering new levels of precision, safety,

and speed that elevate the entire building process.

At the heart of these advanced machines lies unparalleled expertise in engineering and design, making them a cornerstone for creating expansively open spaces without the need for frequent vertical supports, such as columns or pillars. Built with cutting-edge technology, large span forming machines enable architects and engineers to push the boundaries of design while maintaining structural integrity and reducing material waste. This combination of innovation and efficiency results in clear spans that cater to a plethora of architectural visions, from stadiums and bridges to commercial complexes and industrial facilities.

From an experiential standpoint, construction professionals who have operated or integrated large span forming machines into their projects often laud the significant reduction in project timelines. This efficiency arises from the machine’s ability to streamline the fabricating and assembling processes on-site. The comprehensive guidance system and intuitive control interfaces embedded within these machines enable operators to execute even the most intricate span requirements with minimal error. This real-world operational experience underscores the machine's transformative impact on construction timelines, allowing projects to meet, or even exceed, scheduled deliveries.

In terms of expertise, manufacturers have invested heavily in research and development to ensure their machines meet the rigorous standards and evolving challenges of modern construction. This dedication to specialization is reflected in features such as customizable formwork systems, load-bearing capacities designed to handle diverse materials, and adaptive mechanisms that cater to various environmental conditions. These features not only leverage advanced engineering principles but also provide a one-stop solution for large span construction needs, setting a high bar of expectation for any project. The technical support provided by manufacturers further aids in maximizing these machines’ capabilities, ensuring that operators are well-prepared to tackle complex structural challenges.

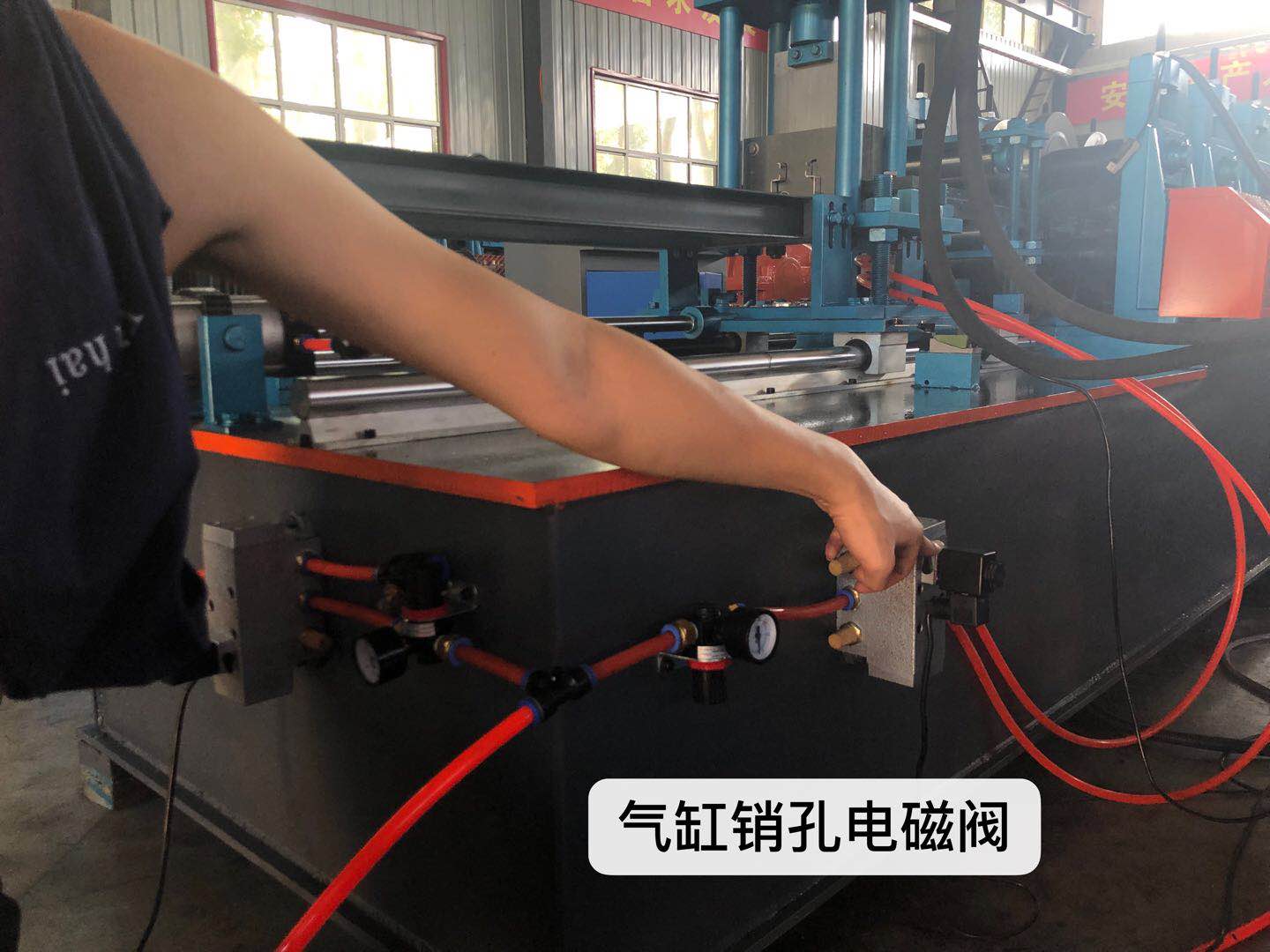

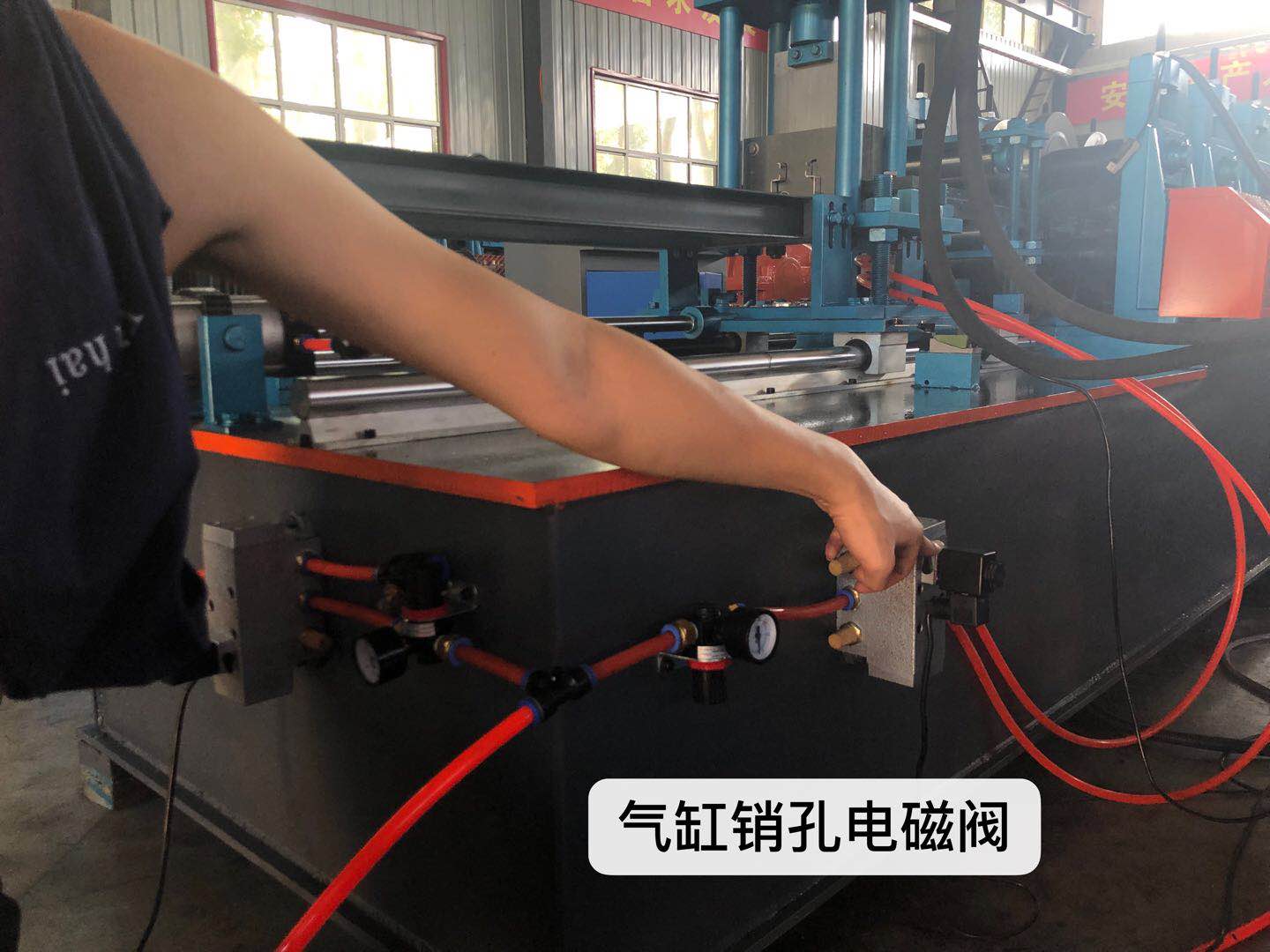

large span forming machine

Authoritativeness in the domain of large span forming machines is often established through accreditation and industry recognition. Products that have undergone rigorous testing and received certifications from construction industry standards bodies are inherently more trustworthy. Such validations not only reinforce the machine's reliability but also affirm its durability and performance under diverse conditions. These endorsements serve as a testament to the machine's standing in the industry, exemplifying a blend of robustness and precision that can be leaned upon for critical construction tasks.

Trustworthiness is a critical attribute for any heavy machinery used in construction, and large span forming machines are no exception. The reputation of these machines is often enhanced by positive testimonials from satisfied clients who have observed firsthand the enhanced quality of construction achieved. Furthermore, companies with a transparent track record of safety compliance, customer service, and post-sales support contribute significantly to the machinery’s reliability. Well-documented maintenance routines and clear operating manuals further enhance user confidence, ensuring that the machine remains a reliable asset throughout the lifecycle of any construction project.

In conclusion, the large span forming machine stands at the forefront of modern construction technology. Its state-of-the-art features, coupled with proven expertise and reputable authority in the industry, make it an indispensable tool for any construction project aiming to achieve large, unimpeded spaces efficiently. By providing credible, top-tier solutions for complex structural challenges, these machines not only exemplify engineering excellence but also build a foundation of trustworthiness and reliability that construction professionals can depend on for successful project outcomes.