The Highway Guardrail Making Machine Ensuring Road Safety Through Innovation

In the modern world, road safety has become an increasingly critical issue as vehicle populations soar. One of the essential components in maintaining safety on highways and roads is the guardrail. These metal barriers protect motorists from hazards such as steep drop-offs, roadside obstacles, and inclement weather conditions. To meet the demands for high-quality guardrails, the highway guardrail making machine emerges as a significant innovation in manufacturing.

The highway guardrail making machine is designed to produce durable, reliable guardrails that can withstand the various forces acting upon them in real-world conditions. These machines employ advanced technology to ensure precision and efficiency throughout the production process. The importance of quality in guardrails cannot be understated; they must absorb impact energy effectively and remain intact to provide maximum protection to drivers.

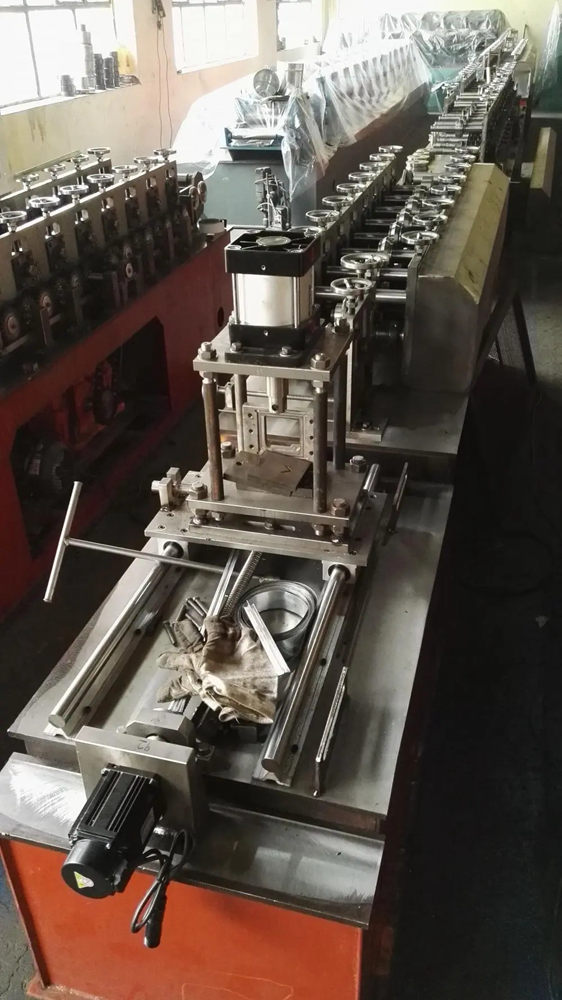

The production process begins with the feeding of raw materials, typically steel coils, into the machine. The machine features several phases, including roll forming, cutting, and welding. Using the roll forming technique, the machine shapes the steel coils into the specific profile required for guardrails. This process not only ensures the correct dimensions but also enhances the material’s strength through continuous, uniform shaping.

After the shaping phase, the next step is cutting the formed steel into the desired lengths. The highway guardrail making machine is equipped with precision cutting tools that guarantee clean and accurate cuts, crucial for maintaining the structural integrity of the guardrails. Following this, the machine may incorporate welding stations that join sections of guardrails together, providing extra strength and stability.

Automated technology plays a crucial role in enhancing production efficiency. The integration of computerized controls allows for precise adjustments during the manufacturing process, optimizing the machine's speed and productivity while minimizing waste. Furthermore, these machines can be adjusted to create various types of guardrails, catering to different safety requirements and road conditions. This versatility is essential for manufacturers looking to meet diverse market needs.

Quality control is another significant aspect of the guardrail manufacturing process. Each batch of guardrails produced undergoes rigorous testing to ensure they meet safety standards and regulations. This includes checks for strength, durability, and resistance to environmental factors such as corrosion.

The introduction of advanced highway guardrail making machines significantly boosts production capacity and efficiency. Manufacturers can meet the increasing demand for guardrails while also ensuring that the products adhere to the highest safety standards. By investing in such machines, companies not only improve their operational efficiency but also contribute to enhancing overall road safety nationwide.

In conclusion, the highway guardrail making machine is an invaluable asset in the quest for safer roads. Through innovative technology and efficient manufacturing processes, it ensures the production of high-quality guardrails that protect lives across the globe. As we continue to prioritize road safety, advancements in manufacturing technology will undoubtedly play a pivotal role in safeguarding our roads for future generations.