High Precision Straightening Machines Advancements in Leveling Technology

In the modern manufacturing landscape, precision is paramount. Industries that rely on metal components, such as automotive, aerospace, and construction, face an increasing demand for high-quality products that meet stringent standards. One of the most critical processes within these industries is the straightening of metal parts, which ensures that components are level and fit for use. High precision straightening machines, also known as leveling machines, are vital for achieving these objectives. This article explores their importance, technology, and impact on various industries.

The Importance of Straightening Machines

Straightening machines are essential in many manufacturing processes that involve metal materials. Metals often undergo stress during manufacturing, which can lead to warping, bending, or uneven surfaces. Such imperfections can compromise the mechanical properties of individual components and ultimately affect the performance and durability of the final product. High precision straightening machines mitigate these issues by correcting deformities and ensuring that parts adhere to specified tolerances.

The advantages of using high precision straightening machines extend beyond mere aesthetic correction. They enhance the overall quality of products, reduce material wastage, minimize non-conformance, and improve the efficiency of manufacturing processes. By producing components that are accurate and true to specifications, companies can reduce the likelihood of defects that would otherwise lead to costly rework and delays.

Advanced Technology in Straightening Machines

The evolution of straightening machines has been significantly influenced by advancements in technology. High precision straightening machines now incorporate sophisticated features that enhance their efficiency and effectiveness.

1. Computer Numerical Control (CNC) Many modern straightening machines use CNC technology to achieve unparalleled precision. This automation allows for complex leveling processes that would be nearly impossible to perform manually. Operators can program the specific requirements for each component, ensuring that each part is treated according to its unique specifications.

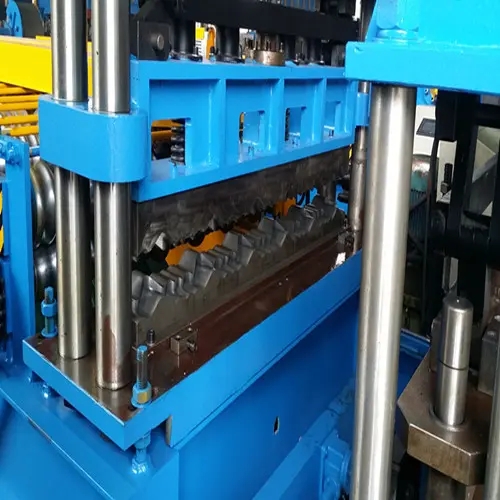

2. Hydraulic Systems State-of-the-art hydraulic systems provide the necessary force for straightening while allowing for fine adjustments. This flexibility makes it possible to handle different types of metals and varying degrees of deformation, making these machines versatile across applications.

3. Laser Measurement Integrated laser measurement systems are commonly used to ensure that the straightening process is executed to exacting standards. These systems provide real-time feedback, allowing operators to make immediate adjustments as needed. The result is a higher level of accuracy and reduced cycle times.

4. User-Friendly Interfaces The introduction of intuitive interfaces makes it easier for operators to manage the straightening process. Modern straightening machines come equipped with touchscreen displays that provide clear instructions and access to historical data for process optimization.

Impact on Various Industries

The impact of high precision straightening machines is felt across multiple industries. In automotive manufacturing, for example, a single bent component can lead to significant issues within a vehicle, including misalignment of the chassis, which could affect safety. Therefore, high precision in straightening is crucial for ensuring vehicle integrity.

In aerospace, where components are subjected to extreme conditions, the need for precision is even more critical. Any deviation from specifications can result in catastrophic failures. High precision straightening machines help ensure that parts meet the rigorous quality standards required for aircraft operation.

Moreover, the construction industry benefits from these machines as well. Steel beams, girders, and other structural elements often need to be leveled to ensure safety and compliance with strict building codes. High precision straightening machines help guarantee that these components are structurally sound and appropriately aligned.

Conclusion

High precision straightening machines play a fundamental role in modern manufacturing, delivering the accuracy needed to produce high-quality metal components. Their advanced technologies not only enhance precision but also ensure efficiency, contributing to reduced costs and improved productivity. As industries continue to evolve and improve, the importance of straightening machines will only grow, solidifying their place as indispensable tools in the quest for perfection in manufacturing processes.