Understanding Gutter Cold Roll Forming Machines

In contemporary construction and manufacturing, efficiency and precision play critical roles in determining a project’s success. One of the essential machinery that has revolutionized the production of building materials is the gutter cold roll forming machine. This innovative equipment specializes in fabricating gutters, which are crucial components for effective drainage systems in residential, commercial, and industrial buildings.

What is a Gutter Cold Roll Forming Machine?

A gutter cold roll forming machine is a piece of industrial equipment designed to convert flat metal sheets into specific shapes and profiles that constitute gutters. Utilizing a continuous bending process, the machine gradually shapes the metal as it passes through a series of rollers. These rollers manipulate the material at ambient temperatures, minimizing energy consumption and preserving the metal's properties.

The Roll Forming Process

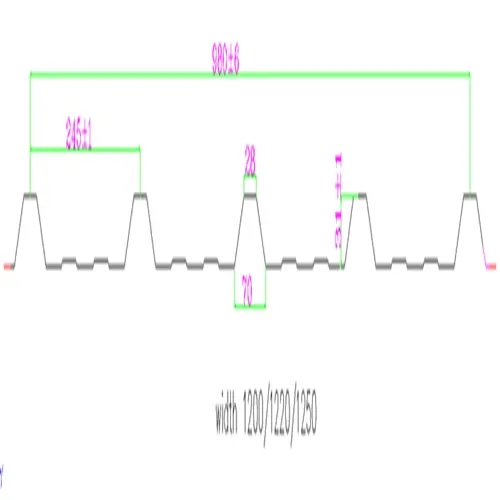

The roll forming process is distinguished by several key stages feeding, forming, cutting, and finishing. The operation begins with the feeding mechanism, where metal coils are carefully unwound and fed into the machine. Following this, the series of rollers sequentially bend and shape the metal into the desired gutter profile. The design ensures uniformity and precision throughout the length of the produced gutter.

Once the metal has been successfully formed, it is cut to the specified lengths using automated cutting systems, which are often integrated into the machine for efficiency. Finally, finishing touches may include additional features such as drainage holes or protective coatings, which can also be incorporated into the process.

Key Features and Benefits

1. Efficiency Gutter cold roll forming machines significantly reduce production times, allowing manufacturers to crank out large quantities of gutters in a short period. This efficiency is crucial in meeting project deadlines without compromising quality.

2. Customization One of the standout features of these machines is their ability to produce customized gutter profiles tailored to specific architectural needs. Manufacturers can easily adjust settings to modify the shape, size, and thickness of the gutters, allowing for greater flexibility in production.

3. Durability and Quality The cold roll forming process enhances the strength and durability of the finished products. The resulting gutters are not only lightweight but also resistant to warping and damage, making them ideal for long-term use in varying environmental conditions.

4. Cost-Effectiveness By streamlining the production process and reducing waste, gutter cold roll forming machines can significantly decrease manufacturing costs. Additionally, the durability of the gutters means fewer replacements and repairs for builders and homeowners.

5. Low Maintenance These machines require less maintenance compared to traditional gutter fabrication methods. Regular checks and minor adjustments can keep the machine in optimal working condition, reducing downtime and maintenance costs.

Applications of Gutter Cold Roll Forming Machines

The gutters produced by these machines are widely used across numerous applications. In residential construction, they are vital for managing rainwater runoff, preventing water damage to siding and foundations. In commercial buildings, proper drainage systems are essential for operational efficiency and long-term structural integrity. Furthermore, industries such as agriculture and transportation benefit from specialized gutter designs, which can be tailored to meet unique drainage needs.

Conclusion

In summary, gutter cold roll forming machines are at the forefront of modern manufacturing, delivering efficiency, flexibility, and high-quality products to meet the demands of various construction projects. As technology advances and industries evolve, the importance of such machinery will only increase, ensuring that builders and manufacturers alike can meet the growing demand for effective, durable, and customizable drainage solutions. Whether in residential or industrial settings, the gutter cold roll forming machine stands as a testament to how innovation drives progress in the construction industry.