The galvanizing pipe making machine stands as a cornerstone in the industrial sector, transforming the way galvanized pipes are manufactured. Its rise in popularity is attributed to its efficiency, durability, and the superior quality of pipes it produces. For professionals in the manufacturing industry, understanding the nuances of this sophisticated machinery is essential for optimizing production and ensuring long-term reliability.

This machine operates at the nexus of cutting-edge technology and industrial ingenuity, converting basic steel into pipes resistant to corrosion and harsh environmental conditions. Galvanization involves coating the steel with a protective layer of zinc, significantly extending the pipe's lifespan and making it suitable for a myriad of applications, including plumbing, construction, and infrastructure projects.

From an expertise standpoint, the machinery's design is a marvel of engineering. It integrates several components, each playing a critical role in the production process. This includes the uncoiler, forming section, welding unit, and the galvanizing station, all meticulously synchronized to ensure seamless operation. The uncoiler feeds steel strips into the system, which are then shaped in the forming section. This precision ensures dimensional accuracy, critical for meeting international standards.

Professional manufacturers leverage advanced welding units within the machine. These units ensure strong seam welds, a crucial factor in preventing leaks and maintaining structural integrity under pressure. Incorporating high-frequency welding technology enhances efficiency and minimizes defects, culminating in a product that exemplifies quality and durability.

The galvanizing process is where the transformative magic happens. Pipes pass through a molten zinc bath, a process that requires meticulous control over temperature and immersion time. Expert operators know that precision in this stage is paramount; any deviation can affect the thickness of the zinc coating, impacting its protective qualities.

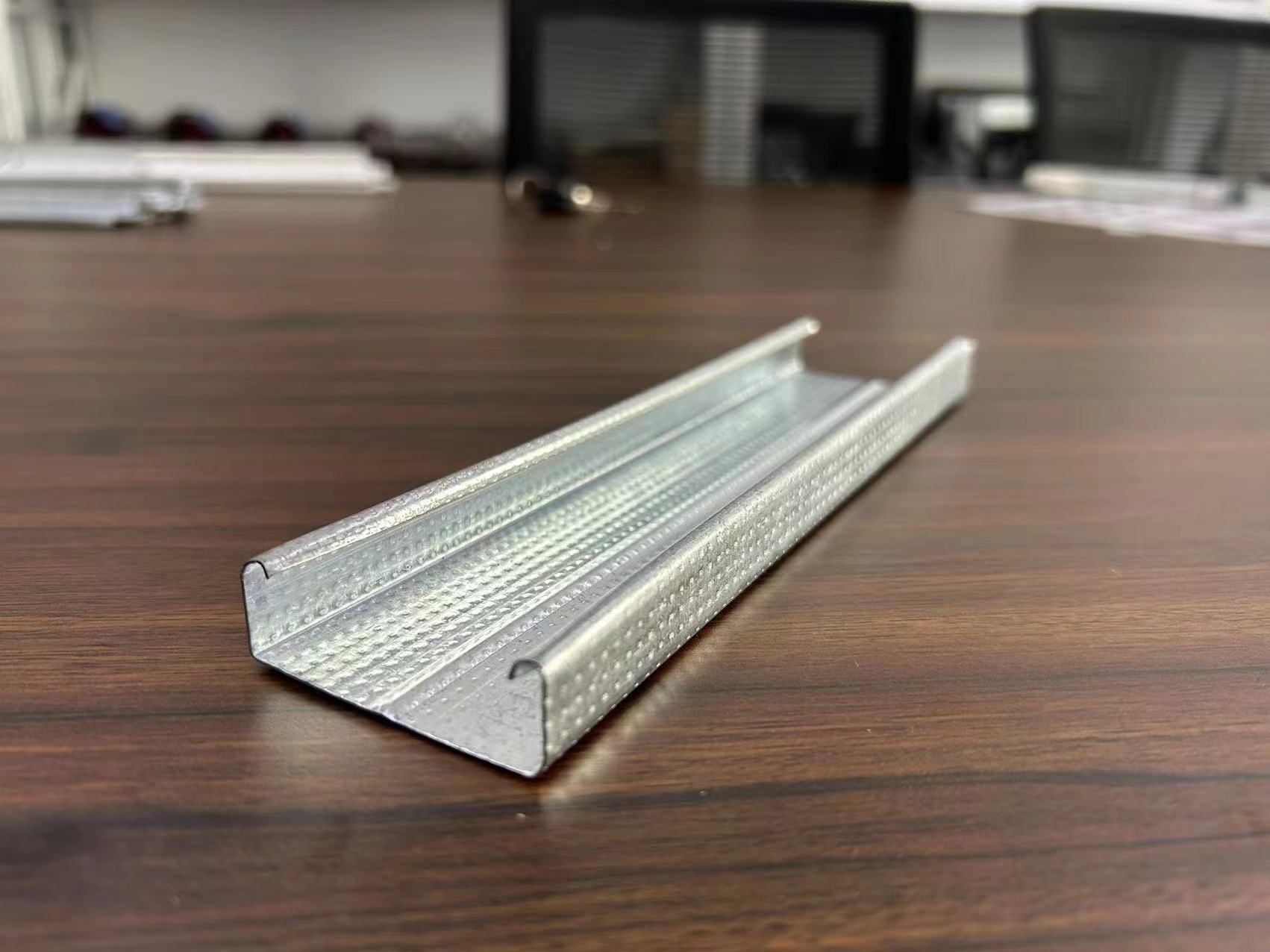

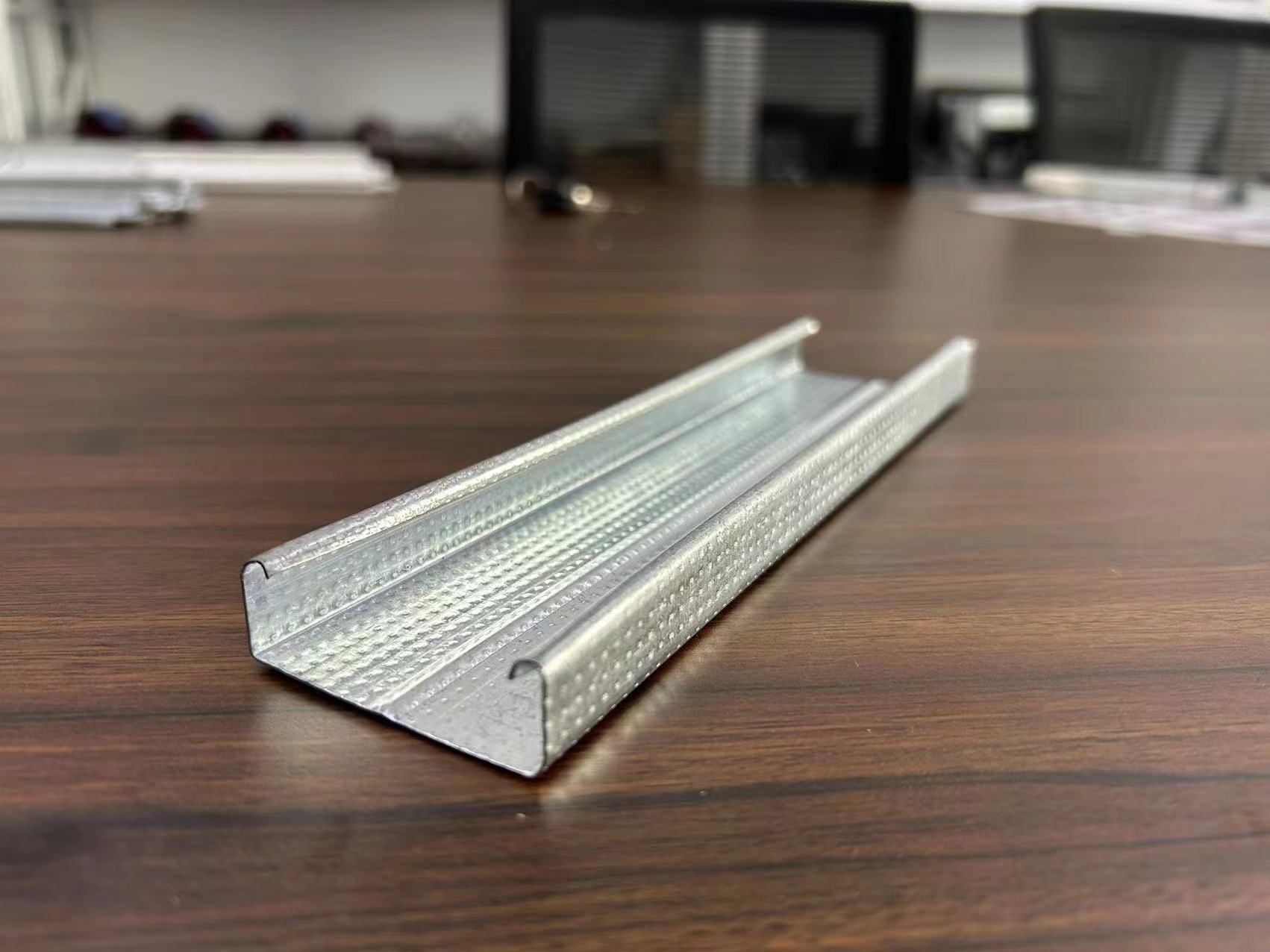

galvanizing pipe making machine

Empirically, the use of galvanizing pipe making machines has been shown to increase production rates and improve the uniformity of the product. This not only enhances the production line's efficiency but also reduces waste, a critical consideration in sustainable manufacturing practices. The integration of automation in modern machines further enhances precision and reduces the need for manual intervention, making it a trustworthy tool for any serious manufacturer.

Possessing deep expertise in operating these machines extends beyond mere technical skills into understanding the evolving needs of the market. As industries demand pipes with specific properties, manufacturers must adjust parameters to match these requirements, demonstrating both the versatility and adaptability of the machine.

Trustworthiness is further cemented through rigorous testing and quality assurance protocols. Each machine undergoes extensive trials to ensure it meets industry standards, providing assurance to users of its reliability and performance consistency. Manufacturers often offer comprehensive training programs, ensuring operators are well-versed in not just the operation, but also routine maintenance and troubleshooting, minimizing downtime.

In addition to its operational benefits, embracing this technology positions companies at the forefront of industrial innovation. It reflects a commitment to quality and a forward-thinking approach to manufacturing, which in turn enhances a company’s reputation and authoritative standing in the market.

In summarizing, the galvanizing pipe making machine is not just a piece of equipment; it is an integral part of modern manufacturing infrastructure. Its expert design, reliable operation, and adaptability make it a critical asset for any enterprise committed to producing high-quality galvanized pipes. As the landscape of industrial production continues to evolve, embracing such technology will prove to be invaluable, reinforcing a company’s reputation as an industry leader committed to excellence.