Understanding Galvanized Standing Seam Roll Forming Machines

In the world of modern construction, efficiency and durability are paramount. One innovative solution that has gained popularity is the galvanized standing seam roll forming machine. This machinery not only streamlines the production of roofing materials but also ensures a high level of quality and durability in the final product. This article will delve into the features, benefits, and applications of galvanized standing seam roll forming machines.

What is a Standing Seam?

Standing seam roofing is a system often used in commercial buildings, industrial structures, and increasingly in residential homes. It consists of vertical panels that are interlocked at the seams, creating a raised profile. The standing seam design allows for thermal expansion and contraction, making it particularly effective in regions with fluctuating temperatures. The vertical seams also contribute to a sleek, modern aesthetic that is highly sought after in contemporary architecture.

Features of Galvanized Standing Seam Roll Forming Machines

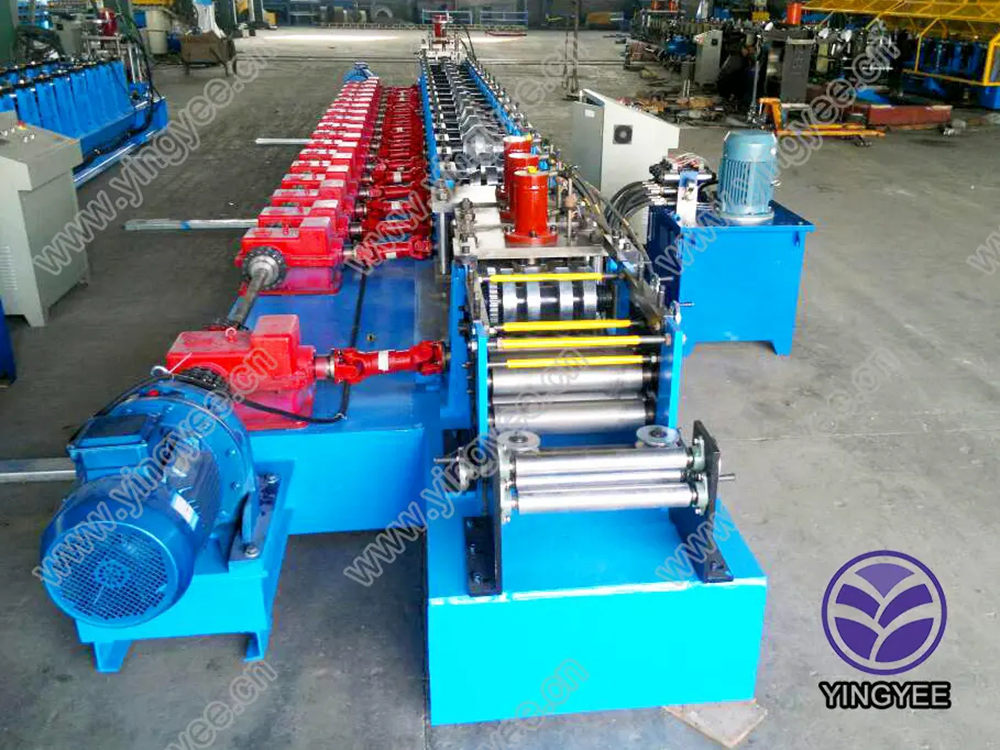

Galvanized standing seam roll forming machines are specifically designed to produce standing seam panels from galvanized steel, recognized for its durability and corrosion resistance. These machines typically incorporate several key features

1. Automatic Control Systems Most modern roll forming machines are equipped with advanced control systems that allow for precise adjustments to be made during the production process. The automation helps to minimize errors and increases production efficiency.

2. High Speed and Efficiency These machines are capable of producing large quantities of panels in a relatively short period. This speed is crucial for meeting project deadlines and keeping labor costs down.

3. Durability and Strength Galvanized steel’s resistance to rust and corrosion ensures that the standing seams produced are long-lasting. This quality is especially important in areas with harsh weather conditions.

4. Customizable Designs Manufacturers can customize the design specifications of standing seam panels, allowing for various widths, heights, and profiles according to client requirements.

Benefits of Using Galvanized Standing Seam Roll Forming Machines

Utilizing galvanized standing seam roll forming machines offers numerous advantages

- Cost Efficiency By producing panels on-site or close to the job location, contractors can save on transportation costs and reduce waste material. The efficient production process also lowers labor costs.

- Longevity and Maintenance Galvanized steel is designed to last. The standing seam design minimizes the risk of leaks and other maintenance issues, making it a practical choice for long-term investments.

- Energy Efficiency Many standing seam roofs can accommodate insulation materials, contributing to better energy performance in buildings. This can lead to significant savings on heating and cooling costs.

Applications of Galvanized Standing Seam Roofs

Galvanized standing seam roofs are versatile and suitable for a variety of applications

1. Commercial and Industrial Buildings Many factories and warehouses utilize standing seam roofs due to their strength and durability. The ability to handle heavy snow loads and high winds makes them ideal for industrial settings.

2. Residential Homes Increasingly, homeowners are opting for standing seam roofs for their aesthetic appeal and long-lasting quality. The sleek lines add a modern touch, making them popular among designers.

3. Institutional Structures Schools, hospitals, and government buildings benefit from the longevity and low maintenance of standing seam roofs, contributing to a lower total cost of ownership.

Conclusion

The galvanized standing seam roll forming machine is a notable advancement in roofing technology, combining efficiency with high-quality output. As the demand for durable, reliable roofing solutions continues to rise, the role of roll forming machines in the construction industry becomes increasingly vital. By investing in such technology, manufacturers and contractors can meet the evolving needs of their clients while ensuring exceptional quality in their products. Whether in commercial, industrial, or residential applications, the use of galvanized standing seam roofs provides an attractive, functional, and enduring solution for modern building requirements.