The Evolution and Importance of Fence Panel Machines

In recent years, the demand for fencing solutions in both residential and commercial applications has surged, leading to significant advancements in manufacturing technologies. Among the most notable innovations in this domain is the fence panel machine. This sophisticated equipment has revolutionized the way fence panels are produced, offering manufacturers greater efficiency, consistency, and quality in their output.

Understanding Fence Panel Machines

A fence panel machine is specifically designed for the automated production of various types of fence panels. These machines can handle different materials such as wood, vinyl, metal, and composite materials, making them versatile solutions for manufacturers. The process typically involves the cutting, assembling, and finishing of the panels, all of which can be done with minimal human intervention. This automation reduces labor costs and increases production rates, allowing businesses to meet growing market demands.

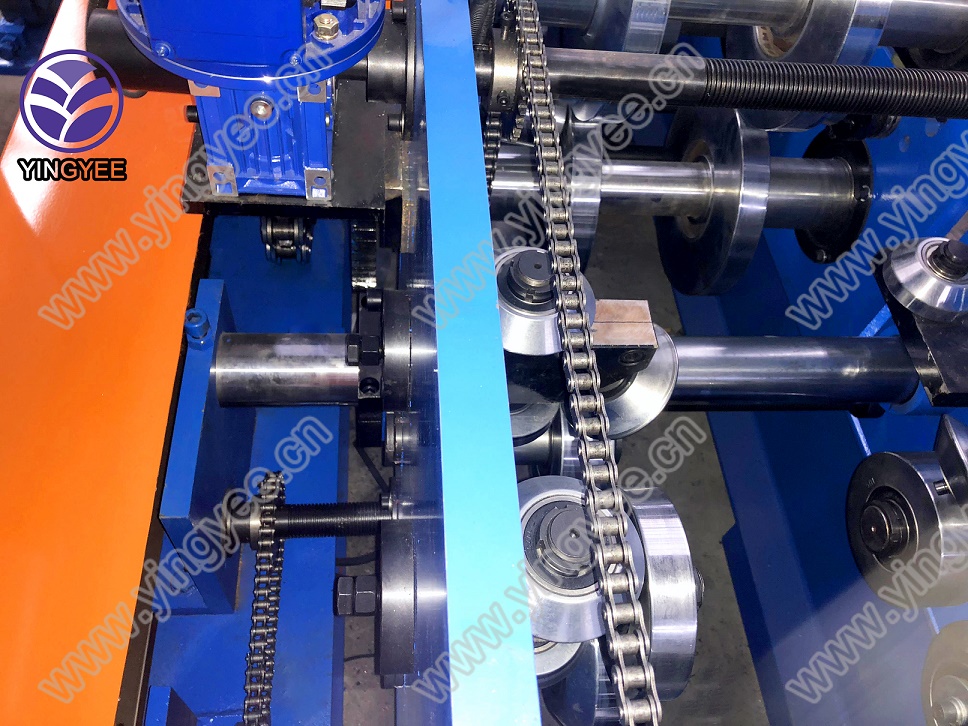

Key Components and Features

Modern fence panel machines come equipped with several advanced features. For instance, they often utilize CNC (Computer Numerical Control) technology for precision cutting and shaping. This ensures that each panel is produced to the exact specifications required by customers, reducing waste and improving overall product quality.

Moreover, the incorporation of robotic arms in some machines helps in the assembly process. These robots can handle heavy materials with ease, automating tasks that would otherwise require multiple workers. Additionally, many machines offer adjustable settings, enabling manufacturers to produce panels of varying sizes and styles, catering to a broad range of customer preferences.

Environmental Considerations

As sustainability becomes a focal point across industries, manufacturers are also addressing environmental concerns in the production of fence panels. Fence panel machines have evolved to operate efficiently while minimizing waste. Some machines are designed to use byproducts from other manufacturing processes, turning what would be waste into high-quality fence panels. Furthermore, manufacturers are increasingly opting for eco-friendly materials such as recycled plastics or sustainably sourced wood, leveraging their fence panel machines to create products that are both durable and environmentally conscious.

Economic Impact

The introduction of fence panel machines has significantly impacted the economy of the fencing industry. By streamlining production and reducing costs, these machines enable manufacturers to offer competitive pricing to their customers. This shift has made quality fencing solutions more accessible to consumers, thus expanding the market. Furthermore, as businesses grow and modernize their production facilities with these automated systems, they create new job opportunities in engineering, maintenance, and machine operation, contributing positively to the local economy.

Future Trends

As technology continues to evolve, we can expect even more advancements in fence panel machinery. Innovations such as AI and machine learning may soon play a role in enhancing efficiency and predictive maintenance, allowing machines to learn from their operational data and optimize workflows. Additionally, the trend towards smart manufacturing will likely see an increase in connected machinery, enabling manufacturers to monitor and control production processes remotely.

The future may also see a rise in customization options, as consumers increasingly seek personalized solutions for their fencing needs. Fence panel machines could be programmed to produce unique designs on demand, allowing businesses to cater to niche markets while maintaining high production levels.

Conclusion

In summary, the fence panel machine has transformed the production landscape of fencing solutions. By embracing automation, manufacturers can enhance efficiency, reduce costs, and meet the diverse needs of their customers. As technology continues to advance, we can expect even greater innovations in this arena, paving the way for a more sustainable and efficient future in the fencing industry. As such, fence panel machines are not just tools of production; they are pivotal in shaping the future of fencing solutions worldwide.