Navigating the world of drywall installation? The drywall profile machine is an indispensable asset for professionals seeking precision, efficiency, and cost-effectiveness. This marvel of engineering, while sometimes overshadowed by its end product, actually serves as the backbone of any superb drywall job, providing consistency and quality that are crucial for both small and large construction projects.

One of the foremost reasons to choose a drywall profile machine is its unparalleled precision in producing profiles. These machines are tailored to fabricate metal frames that match exacting specifications. The precision ensures that every piece of metal is cut and formed to fit perfectly, reducing waste and increasing efficiency. This not only leads to a better-quality finish but also minimizes subsequent adjustments or fixes needed onsite, saving valuable time and resources.

From an expertise standpoint, these machines offer variability and adaptability, making them suitable for producing a variety of drywall profiles such as U-shaped, C-shaped, L-shaped, and Omega profiles. For professionals who need to meet the specific requirements of diverse projects, being able to generate exact profiles quickly can be a significant advantage. The versatility of the machines means they can handle both standard and custom jobs, enabling specialists to fulfil client demands without delay.

Expertly designed, the technology behind drywall profile machines has advanced dramatically. They integrate high technology like computer numerical control (CNC) systems that enhance consistency and accuracy. CNC systems allow for the crafting of complex designs and patterns with ease, opening opportunities for more creative and custom architectural elements. The incorporation of CNC technology underscores the authority of these machines in modern construction environments—where precision is paramount, and errors are costly.

When delving into authoritativeness, it becomes clear that machines from reputable manufacturers come with rigorous testing to adhere to international construction standards. This not only guarantees performance but also ensures compliance with building and safety regulations, which is non-negotiable in this industry. The assurance that these machines are enhancing the structural integrity of construction work boosts confidence among architects, builders, and their clients.

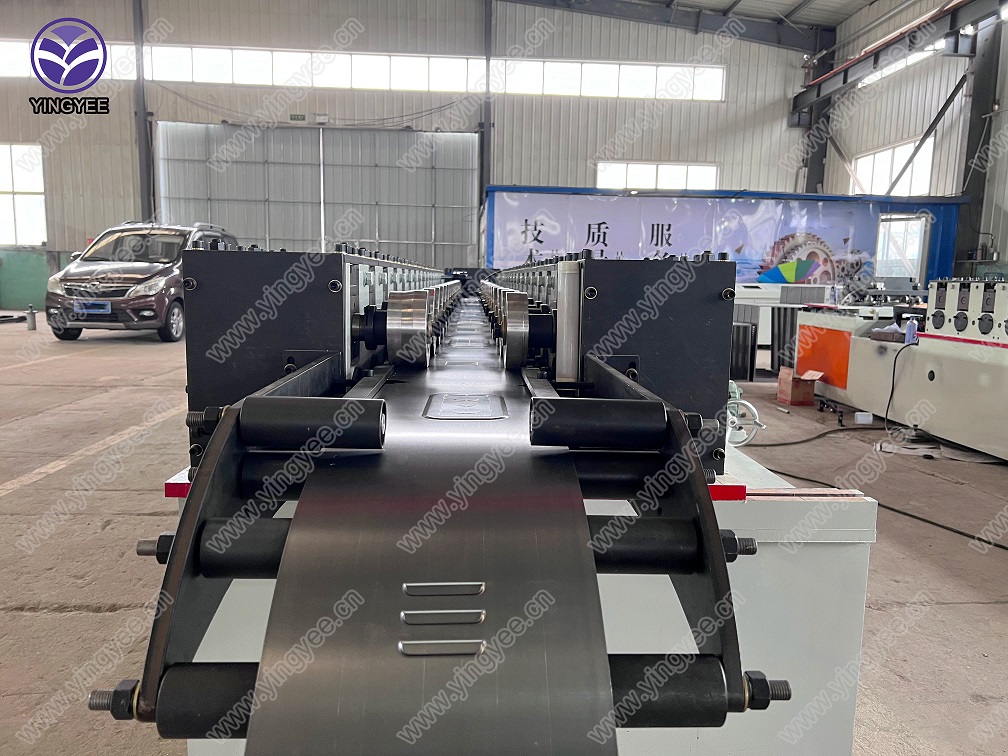

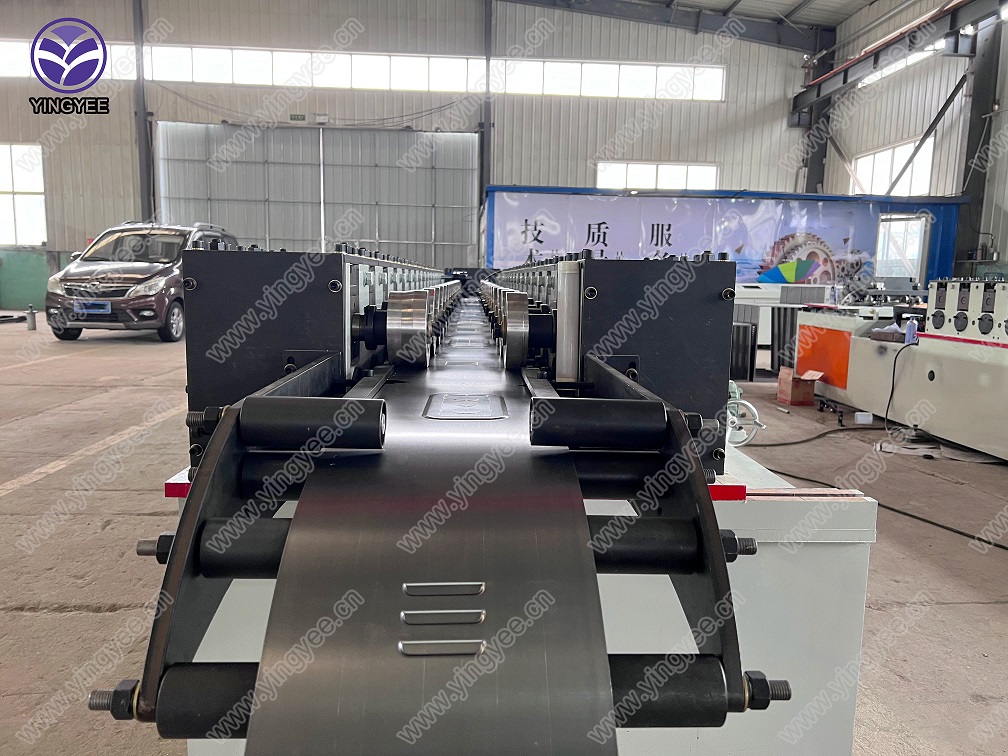

drywall profile machine

In terms of trustworthiness, the durability and robustness of the drywall profile machine are indisputable. Modern machines are built to last, offering years of reliable service with minimal maintenance. This reliability reduces the total cost of ownership over time, a critical factor for businesses mindful of their bottom line. Manufacturers often provide extensive warranties and customer support,

further cementing the trust that operators can place in these machines.

Adopt a drywall profile machine into your workflow and the transformation in operational quality is notable. The machine's ability to handle high volumes of production efficiently amplifies output without compromising on quality. This balance between quality and quantity is why contractors and large-scale builders gravitate towards these machines as a sustainable solution to meet demanding project timelines.

Moreover, using a drywall profile machine enhances the working conditions in the field. With pre-sized and pre-shaped profiles, installations become quicker and more straightforward, reducing the physical strain on workers and diminishing the likelihood of onsite accidents. These ergonomic benefits translate to a healthier, more satisfied workforce, resulting in better productivity and reduced turnover—an often-overlooked advantage in a labor-intensive industry.

Therefore, investing in a drywall profile machine signifies a strategic approach to elevate your construction services. It amalgamates efficiency, precision, and reliability, offering a balanced solution to meet both current and future demands of drywall applications. With the ever-evolving landscape of construction, staying ahead with technology-driven solutions like these machines ensures your projects stand out for their quality and professionalism.