In the intricate realm of modern construction, the double layer roofing sheet forming machine stands out as a versatile workhorse that bridges the gap between simplicity and innovation. In the pursuit of high-quality, efficient roofing solutions, a double layer roofing sheet forming machine emerges as a quintessential tool that can redefine architectural possibilities.

Navigating the specifics of the double layer roofing sheet forming machine reveals its unique capability of producing two distinct profiles from a single system. This dual-functionality optimizes space, capital expenditure, and operational efficiency—a trifecta that resonates profoundly with construction companies looking to elevate productivity while ensuring sustainability.

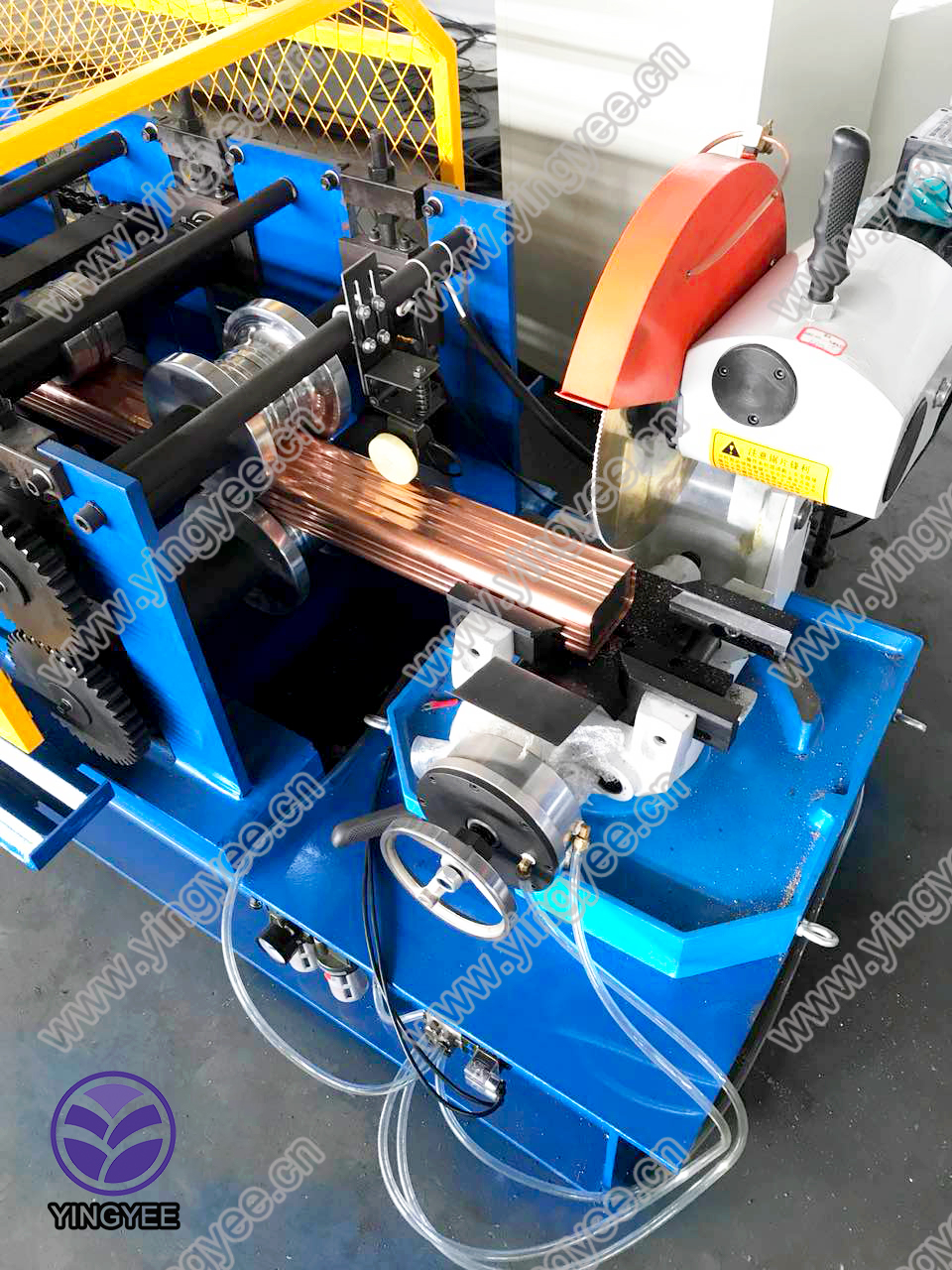

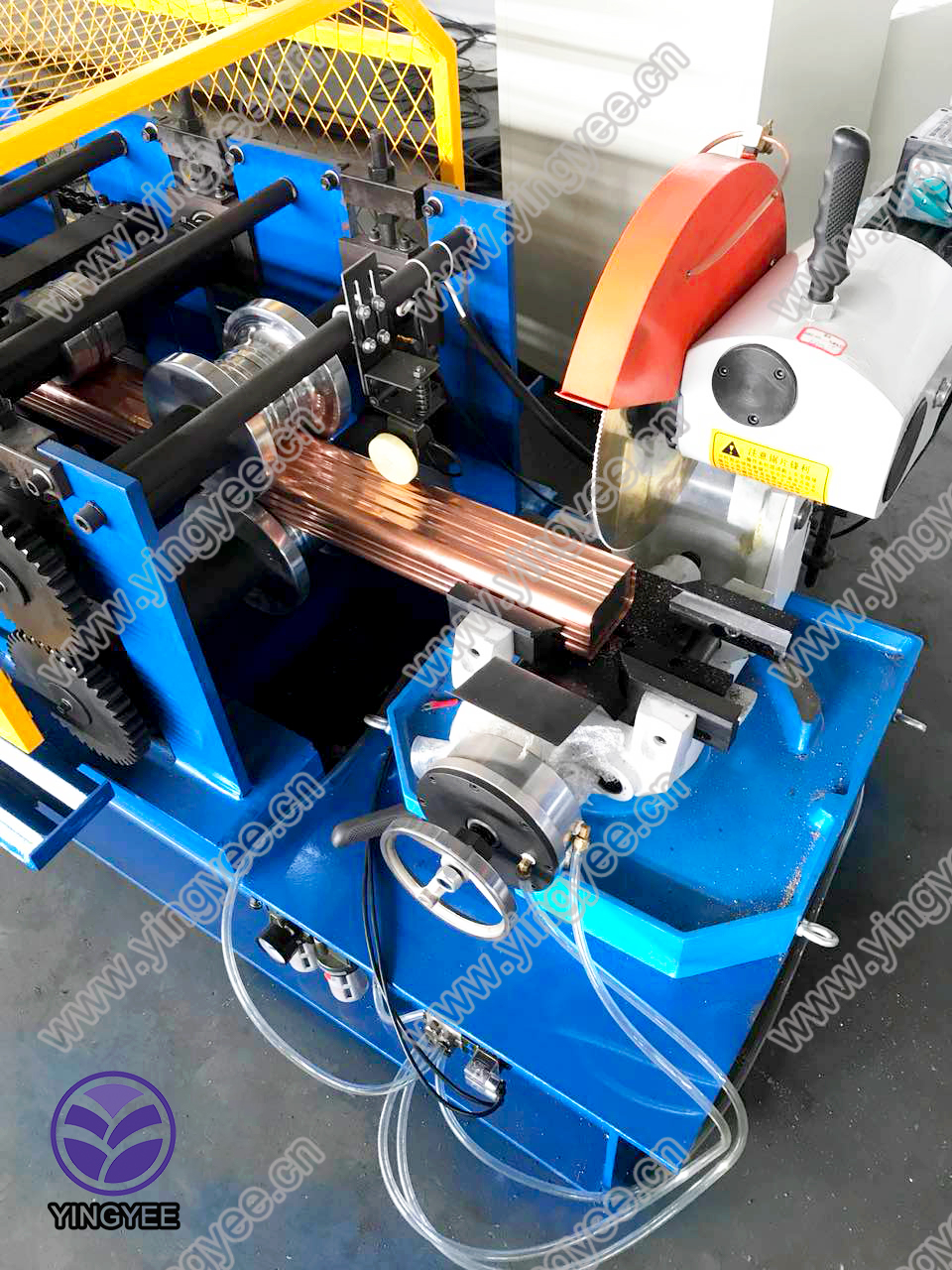

The hallmark of this technology lies in its meticulous engineering, allowing for seamless transitions between different profiles with minimal disruption. This is particularly crucial in fast-paced construction environments where time is of the essence. The machine, typically controlled by advanced PLC systems, empowers operators to manage precision and consistency in production, thereby reducing human error and waste. What truly sets a high-quality double layer machine apart is its ability to maintain robustness and reliability while operating under demanding production schedules.

Expertise in operating these machines extends beyond mere technical manipulation; it involves a deep understanding of roofing material behaviors and the specific demands of various construction projects. Operators trained in leveraging such technology can optimize the variety of shapes and materials, tailoring output to meet diverse architectural styles and structural requirements. This adaptability not only meets aesthetic aspirations but also aligns with functional imperatives such as durability and weather resistance, essential for enduring roofing solutions.

Authoritativeness in this niche is synonymous with innovation and compliance. Leading manufacturers ensure their machines comply with international safety standards and environmental regulations. This commitment to quality assurance enhances trust and reinforces market credibility. As regulations around construction become more stringent, machines that provide precise production capability with minimal environmental footprint are not only preferred but expected.

double layer roofing sheet forming machine

Trustworthiness, in the context of double layer roofing sheet forming machines, is often a byproduct of profound research and development investment. Transparent documentation, customer support, and performance guarantees play pivotal roles in building clientele confidence. When a brand can consistently deliver on promises of efficiency, durability, and cost-effectiveness, it cements its position as a trusted innovator in the market.

However, the true testament to the trust in these machines comes from real-world applications. Construction projects worldwide, ranging from residential developments to commercial complexes,

bear testament to the reliability and versatility of double layer roofing sheet forming technology. Architects and builders, armed with the capabilities of such advanced machinery, can confidently push the boundaries of design and functionality.

Looking forward, the evolution of these machines is geared towards further automation and integration with digital platforms. The advent of IoT and Industry 4.0 is paving the way for even smarter, more interconnected machinery that promises better diagnostics, predictive maintenance, and enhanced production analytics. These advancements will not only streamline operations but also provide insightful data to further optimize construction practices.

In summary, a double layer roofing sheet forming machine is more than just a mechanical device; it is a sophisticated system embodying efficiency, adaptability, and trust. For businesses in the construction industry, investing in such technology is a strategic move that aligns with the future of building—in a world where quality, resilience, and environmental responsibility are non-negotiable standards.