Understanding C Shape Purlin Roll Forming Machines

In the construction and manufacturing industry, the need for high-quality, durable materials is paramount. One essential component that has gained immense popularity is the C shape purlin, primarily used in building frames. To produce these versatile purlins efficiently, C shape purlin roll forming machines have emerged as a vital tool.

What are C Shape Purlins?

C shape purlins are horizontal supports used in buildings, especially for roofs and walls. They offer excellent structural integrity and are favored for their ability to withstand heavy loads. Their distinct C profile allows them to be lightweight yet robust, making them suitable for a variety of applications from commercial buildings to agricultural structures. The use of C shape purlins not only enhances the stability of a construction project but also improves energy efficiency when combined with insulated panels.

The Role of C Shape Purlin Roll Forming Machines

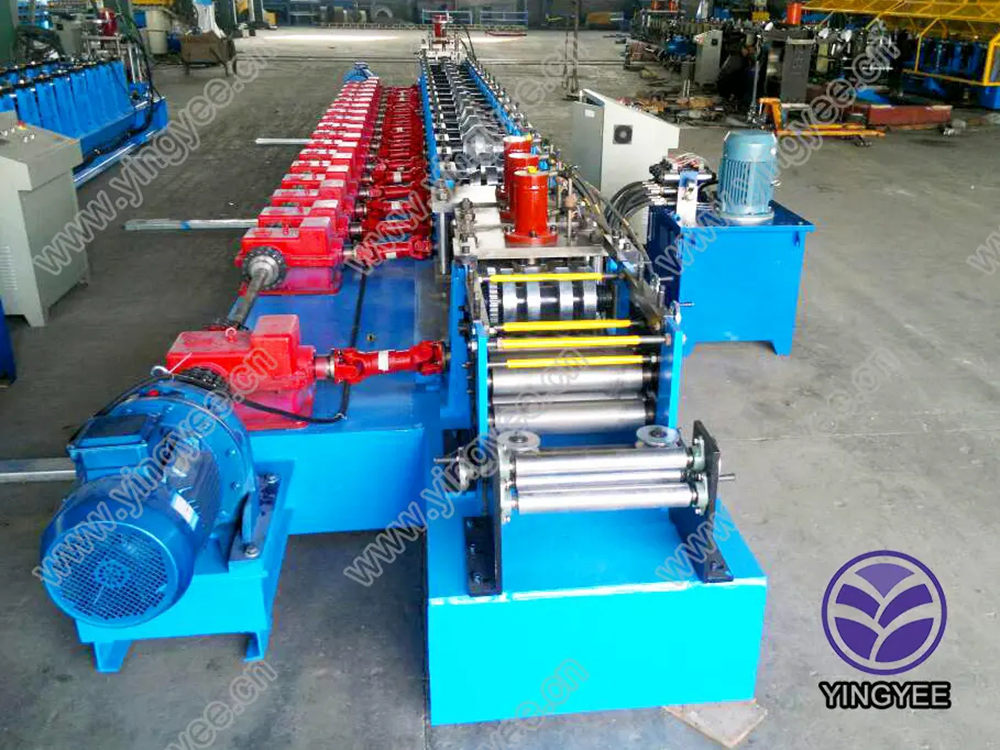

The C shape purlin roll forming machine plays a crucial role in the manufacture of these essential components. This machine transforms flat steel sheets into C-shaped profiles through a continuous bending process. The process involves several steps, including decoiling, leveling, roll forming, cutting, and sometimes punching or notching—depending on the specific requirements of the application.

1. Decoiling Initially, the flat steel coil is uncoiled and fed through a leveling machine to ensure the material is perfectly flat before the forming process.

2. Roll Forming Next, the flat sheet passes through a series of rollers which gradually shape the steel into the desired C profile. Each set of rollers is designed to mold the material incrementally until the final shape is achieved.

3. Cutting Once formed, the length of each purlin is determined and cut to size. This cutting can either be manual or automated, depending on the modernity of the machine.

4. Finishing Processes Additional processes such as punching holes for bolts or notching are often performed to increase the utility of the purlins upon installation.

Advantages of Using C Shape Purlin Roll Forming Machines

The adoption of C shape purlin roll forming machines brings several advantages to manufacturers and builders alike

- Efficiency These machines significantly reduce production time, allowing manufacturers to produce large quantities of purlins quickly without compromising quality.

- Customization Modern roll forming machines are equipped with advanced technology, enabling manufacturers to produce custom shapes and sizes according to specific project needs.

- Cost-Effectiveness By streamlining the production process, businesses can lower labor costs and material waste, making it a cost-effective option.

- Durable Products The roll-forming process enhances the material's strength, resulting in purlins that are durable and reliable under various conditions.

- Minimal Maintenance With fewer moving parts and robust construction, these machines require less maintenance, ensuring continuous operations and reducing downtime.

Applications of C Shape Purlins

C shape purlins are widely utilized in numerous structures such as warehouses, factories, and agricultural buildings. They are integral in supporting roofs, facilitating quick construction timelines without compromising structural integrity. Their versatility extends to usage in mezzanines, awnings, and even in automotive applications.

Conclusion

C shape purlin roll forming machines are essential in today's manufacturing landscape, facilitating the efficient production of high-quality, durable purlins. As the demand for innovative and sustainable building materials continues to grow, these machines stand at the forefront, driving advancements in construction methods. Understanding their operation and benefits not only aids manufacturers in optimizing production but also empowers builders to make informed decisions in their construction projects, ensuring safety, efficiency, and longevity.