The C-Shaped Steel Purlin Roll Forming Machine Revolutionizing Construction and Structural Solutions

The construction industry is ever-evolving, and one significant advancement within this domain is the introduction of the C-shaped steel purlin roll forming machine. This machine has become an indispensable tool for manufacturers and contractors looking to provide efficient, cost-effective, and high-quality steel components for various building structures. In this article, we will explore the functionality, advantages, and applications of C-shaped steel purlin roll forming machines.

Understanding the C-Shaped Steel Purlin

C-shaped steel purlins are horizontal members used to support roofs, walls, and floors in construction. They are named for their distinct C shape, which provides excellent structural strength without excessive weight. These purlins are widely utilized in commercial construction, industrial buildings, and agricultural structures due to their durability and cost-effectiveness. The design allows for efficient load distribution, making them ideal for a variety of applications.

The Role of Roll Forming Machines

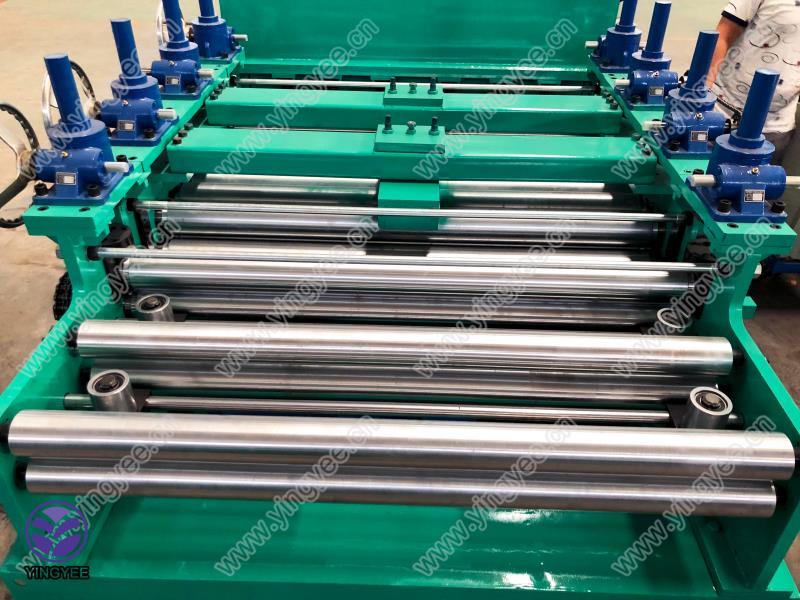

Roll forming machines are essential in the manufacturing process of C-shaped purlins. These machines operate through a continuous bending operation, where a long strip of metal, usually steel, is passed through a series of rollers. As the strip moves through the machine, it is progressively shaped into the desired profile. The roll forming process allows for high production speeds and consistent quality, making it a preferred method for producing C-shaped steel purlins.

Key Features of C-Shaped Steel Purlin Roll Forming Machines

Modern C-shaped steel purlin roll forming machines come equipped with various features that enhance efficiency and productivity

1. Automated Control Systems Many machines are fitted with advanced automation technology, allowing for precise control over the roll forming process. This includes programmable settings for different profiles, lengths, and thicknesses, ensuring flexibility and adaptability to various project requirements.

2. High-Quality Materials These machines are designed to work with a range of materials, including galvanized steel, stainless steel, and other high-strength alloys. The ability to use different materials expands the scope of applications for the finished purlins.

3. Fast Production Rates C-shaped steel purlin roll forming machines can produce large quantities of purlins in a relatively short amount of time. This rapid production capability helps to meet the demands of large construction projects without compromising on quality.

4. Customization Options Many manufacturers offer customizable solutions, allowing clients to tailor the machine settings to meet specific project needs. This includes adjustments for size, thickness, and profile shape.

5. Durability and Maintenance Built with robust materials, these machines are designed for longevity and minimal maintenance. Regular upkeep ensures consistent performance, reducing downtime and operational costs.

Advantages of Using C-Shaped Steel Purlin Roll Forming Machines

The benefits of utilizing C-shaped steel purlin roll forming machines are numerous

1. Cost-Effectiveness By producing steel purlins in-house, companies can significantly reduce costs associated with outsourcing or purchasing pre-manufactured components. This is especially beneficial for large-scale projects with extensive material requirements.

2. Quality Control With in-house production, manufacturers have greater control over the quality of the purlins, ensuring they meet industry standards and project specifications.

3. Versatility These machines can produce purlins in various sizes and dimensions, making them suitable for a wide range of construction projects, from residential buildings to large commercial structures.

4. Reduced Waste The roll forming process is efficient, producing minimal scrap material compared to traditional metalworking methods. This not only reduces costs but also supports environmentally friendly practices.

5. Speed of Construction Quick production times translate to faster construction schedules, allowing projects to progress more rapidly and helping to meet tight deadlines.

Applications in the Construction Industry

C-shaped steel purlins manufactured using roll forming machines are used in various applications

- Roof Support Providing the necessary structural integrity for roofs in warehouses, factories, and agricultural buildings. - Wall Framing Serving as vital structural components in wall framing systems, enhancing overall building stability. - Sign Structures Used in the construction of signage posts and frames due to their strength and lightweight nature.

In conclusion, C-shaped steel purlin roll forming machines are a vital component of modern construction practices. With their ability to produce high-quality, cost-effective components rapidly and with minimal waste, these machines revolutionize the way structural elements are manufactured and utilized in the building industry. As technology continues to advance, the capabilities of these machines will likely expand, further enhancing their value in construction and structural applications.