Understanding Corrugated Sheet Roll Forming Machines

Corrugated sheet roll forming machines play a significant role in modern manufacturing, particularly in the production of corrugated metal sheets used in various applications, including construction, roofing, and storage solutions. These machines are designed to continuously convert flat metal sheets into corrugated profiles through a series of rolls that shape the material while it passes through.

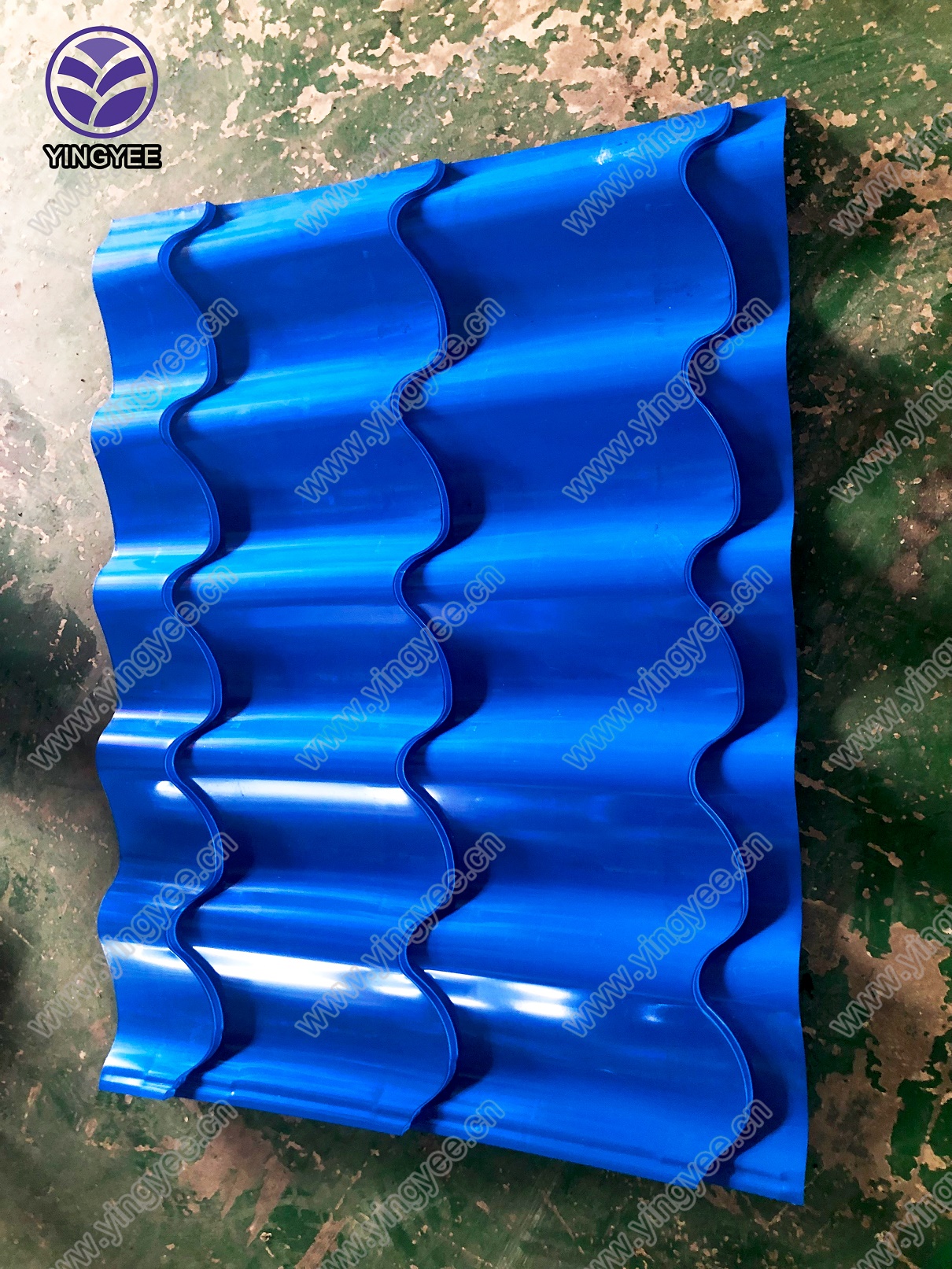

The primary function of a corrugated sheet roll forming machine is to enhance the mechanical properties of the metal, such as strength and rigidity, by creating corrugations—undulating shapes that increase surface area and structural integrity. This transformation is vital for producing materials that can withstand uneven loads and harsh environmental conditions, making them ideal for industrial and commercial use.

One of the key advantages of using corrugated sheet roll forming machines is their efficiency. These machines operate continuously, allowing for high production rates and minimal waste. The precision engineering involved in the design of roll forming machines ensures that the sheets produced are uniform in quality and size, which is crucial for applications that require exact specifications.

Moreover, the versatility of corrugated sheet roll forming machines allows manufacturers to create various corrugated profiles and thicknesses, catering to different market demands. From roofing sheets to wall panels and even decorative elements, these machines can be adjusted to produce sheets that meet specific customer requirements. The ability to switch between different profile designs quickly is a significant asset for manufacturers aiming to remain competitive in a fast-paced marketplace.

Besides efficiency and versatility, the technology behind corrugated sheet roll forming has advanced significantly. Modern machines come equipped with automated controls, allowing for precise adjustments to speed, pressure, and formation angles. This automation reduces labor costs and minimizes the risk of human error, ensuring consistent product quality.

Another important aspect of corrugated sheet roll forming machines is their contribution to sustainability. The use of recyclable materials, such as galvanized steel or aluminum, in the production of corrugated sheets fosters environmentally friendly practices in the construction and manufacturing sectors. By investing in these machines, companies can promote a sustainable approach while also meeting the growing demand for eco-friendly building materials.

In conclusion, corrugated sheet roll forming machines are integral to the efficient production of high-quality corrugated metal sheets. Their ability to combine efficiency, versatility, and advanced technology makes them a fundamental asset in various industries. As manufacturers continue to seek innovative solutions to meet consumer demands, the importance of these machines is likely to grow, further solidifying their place in modern manufacturing processes. Investing in a high-quality roll forming machine can lead to improved productivity, enhanced product quality, and a stronger competitive edge in the market.