The Advancements in Cold Bending Making Machinery

Cold bending making machinery has revolutionized the way industries approach the fabrication of metal components. This innovative technology allows manufacturers to shape and form materials at room temperature, thereby enhancing material properties and ensuring precise geometries. Cold bending processes have gained significant traction in various sectors, including construction, automotive, and aerospace, where durable and lightweight structures are paramount.

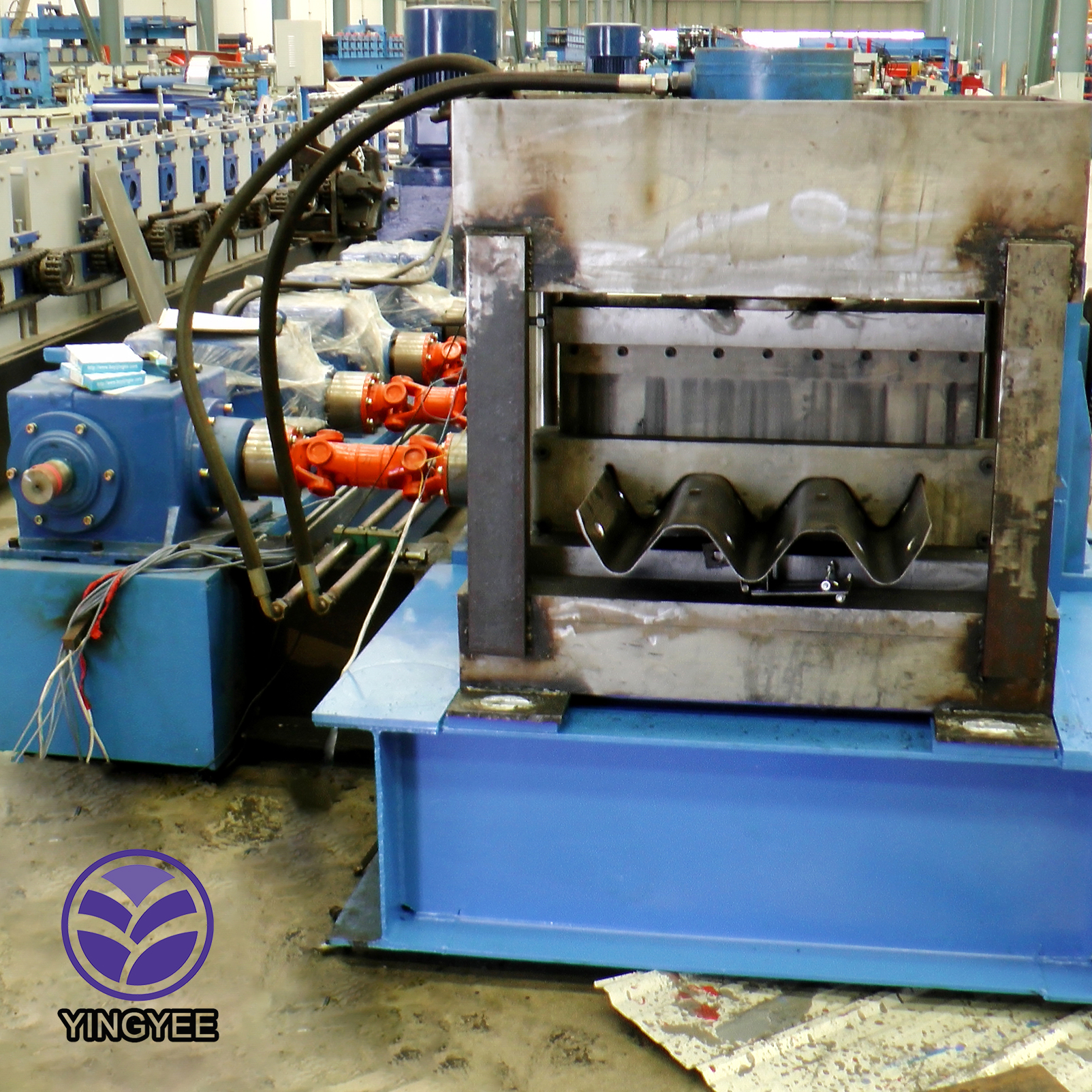

At the heart of cold bending technology is the machinery designed specifically for the task. These machines utilize advanced methods such as roll forming, press brake bending, and tube bending to create intricate shapes from metal sheets or rods. The precision offered by these machines minimizes waste and maximizes efficiency, establishing a new standard for production lines.

One of the key advantages of cold bending machinery is the inherent strength and durability it imparts to the finished products. When materials are bent at room temperature, they retain their mechanical properties better than when subjected to high temperatures. This is especially crucial in applications where structural integrity is non-negotiable. As a result, manufacturers can produce thinner, lighter components without the risk of compromising strength, leading to enhanced performance in end products.

Additionally, cold bending making machinery has a reduced environmental impact compared to traditional hot bending processes. The latter often requires significant energy consumption and can lead to increased emissions. By employing cold bending techniques, manufacturers can lower their carbon footprint while still achieving high-quality results. This eco-conscious approach aligns with the global push toward sustainability and responsible manufacturing practices.

The versatility of cold bending machinery is another significant benefit. These machines can work with various materials, including steel, aluminum, and even certain types of plastics. The ability to adapt to different products and specifications makes cold bending an attractive option for manufacturers looking to diversify their offerings. Moreover, these machines can be integrated with smart technology, allowing for real-time monitoring and adjustments during the production process, further enhancing efficiency and precision.

In conclusion, the advancements in cold bending making machinery have drastically transformed the way metal components are fabricated. By enabling manufacturers to create strong, lightweight, and environmentally-friendly products, this technology is paving the way for innovations across multiple industries. As production techniques continue to evolve, cold bending machinery stands out as a vital component in the pursuit of efficiency and sustainability. Manufacturers equipped with these machines are not just keeping pace with industry demands but are also setting new benchmarks for quality and performance in the fabrication of metal components.