Understanding China Gutter Roll Forming Machines

In the modern construction and manufacturing landscape, the importance of efficient and versatile machinery cannot be overstated. Among these, the gutter roll forming machine is particularly notable for its role in producing seamless and high-quality gutters. China has emerged as a leading manufacturer of these machines, offering a blend of advanced technology, cost-effectiveness, and reliable performance.

What is a Gutter Roll Forming Machine?

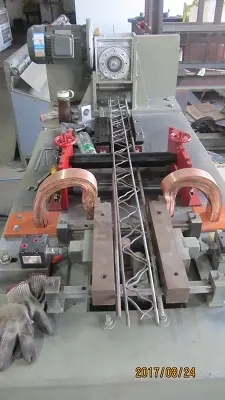

A gutter roll forming machine is a specialized piece of equipment designed to create metal gutters from coiled sheet metal. The process involves feeding metal sheets into the machine, where they are shaped into the desired profile through a series of rollers. This continuous forming process ensures that a uniform product is produced, which is crucial for effective water drainage and overall architectural aesthetics.

The machines are capable of producing various gutter profiles, including K-style and half-round gutters, and can work with different materials such as aluminum, galvanized steel, and stainless steel. The flexibility in design and material selection allows manufacturers to meet diverse customer needs, making these machines valuable assets for contractors and builders.

Key Features of Chinese Gutter Roll Forming Machines

Chinese gutter roll forming machines are celebrated for several features

1. High Efficiency These machines are designed for high-speed production, enabling manufacturers to meet large-scale demands without compromising quality. The automation aspect reduces the time and labor needed to produce gutters.

2. Customizable Designs Manufacturers can customize the machines to produce specific gutter profiles and sizes according to market demands. This adaptability is crucial for businesses aiming to stand out in a competitive market.

3. Durability and Reliability Built with robust materials and advanced technology, Chinese gutter roll forming machines are designed for long-term use. Proper maintenance ensures they can withstand the rigors of continuous production.

4. User-Friendly Technology Many modern machines come equipped with digital controls and intuitive interfaces, allowing operators to easily adjust settings and monitor production in real-time.

5. Cost-Effectiveness China provides affordable manufacturing solutions without sacrificing quality. This cost benefit allows companies to invest in high-performance machinery while keeping operational costs low.

Why Choose China?

China has solidified its position as a leading supplier of roll forming machines due to its significant investments in technology and manufacturing capabilities. The country is home to numerous manufacturers that specialize in producing a variety of roll forming machines, including gutter production systems. This specialization means that buyers can benefit from a wealth of experience and expertise.

Furthermore, the global reach of Chinese manufacturers ensures that businesses from various regions can access these machines. The competitive pricing coupled with the ability to customize machines for specific needs makes China an attractive option for manufacturers worldwide.

Conclusion

Gutter roll forming machines are an essential asset for the construction industry, particularly for producing efficient drainage solutions. China’s role in this market is critical, providing high-quality, durable, and cost-effective machinery that meets the diverse needs of manufacturers globally. As the demand for sustainable and efficient construction practices continues to rise, investing in modern gutter roll forming machines from China can offer businesses a significant competitive advantage. Whether you are a contractor, a builder, or a manufacturer, considering these machines may well be your next step toward improving efficiency and product quality.