Understanding Changeable U Purlin Roll Forming Machines

In the realm of modern construction and manufacturing, the use of purlins—horizontal members in a roof or wall system—is crucial for providing structural support. Among the various types of purlins, U-shaped purlins are widely popular due to their versatility and strength. This is where the changeable U purlin roll forming machine comes into play, revolutionizing the way manufacturers produce these essential components.

What is a U Purlin?

Before delving into the specifics of the roll forming machine, it’s essential to understand what a U purlin is. Typically fabricated from steel, U purlins are named for their distinctive shape that resembles the letter 'U'. They serve as a critical structural element in buildings, supporting roofs, walls, and other loads. U purlins are favored for their ability to distribute weight evenly, providing stability and facilitating efficient construction processes.

The Need for a Changeable U Purlin Roll Forming Machine

Traditional methods of manufacturing U purlins can be labor-intensive, requiring multiple setups and a significant amount of time to produce different sizes and specifications. As construction projects often demand various dimensions and profiles, manufacturers face a substantial challenge how to produce a diverse range of purlins efficiently and affordably.

This challenge has led to the development of changeable U purlin roll forming machines. These machines are designed to produce U purlins of varying sizes with minimal downtime, thus enhancing efficiency and reducing production costs.

How Does a Changeable U Purlin Roll Forming Machine Work?

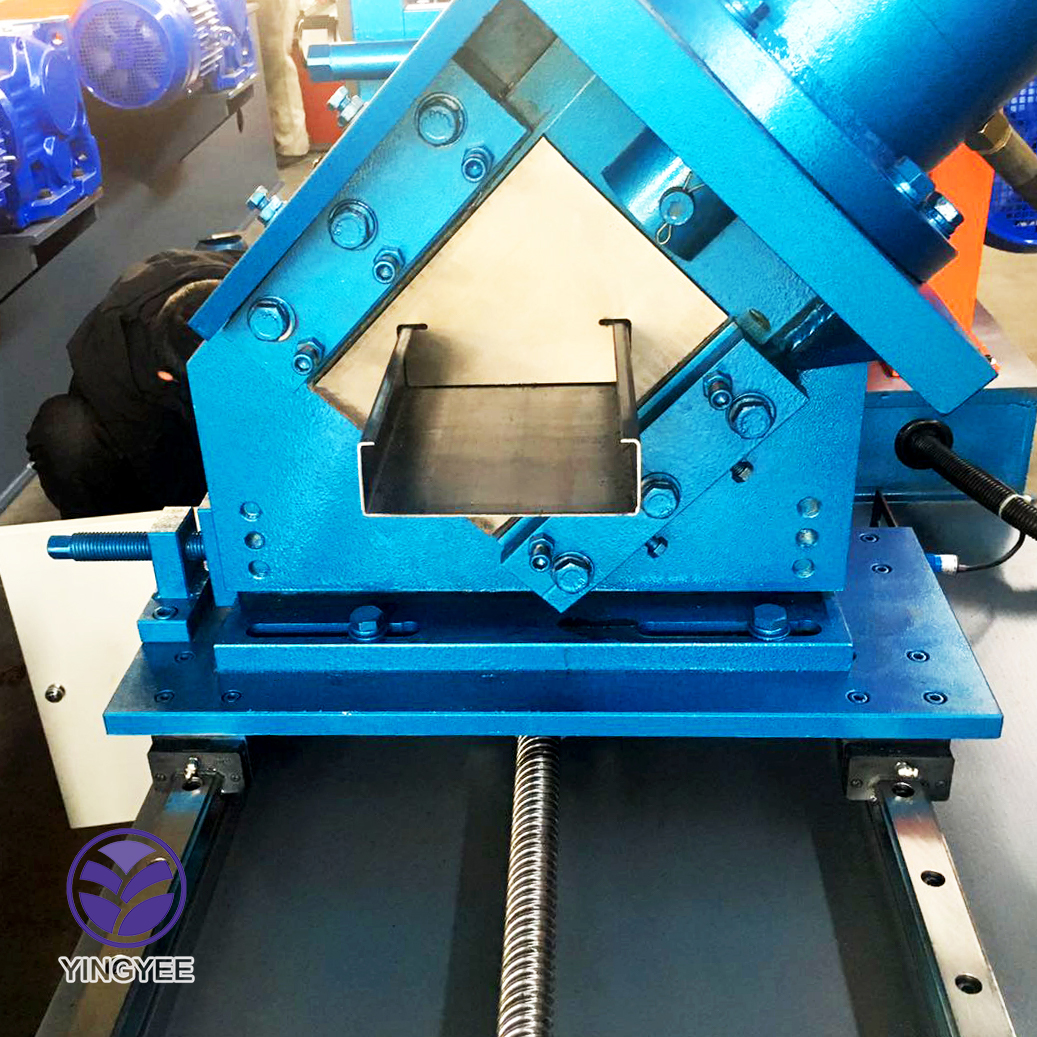

A changeable U purlin roll forming machine typically consists of several key components

1. Decoiler This is where the raw material, usually in the form of steel coils, is loaded. The decoiler unwinds the coil and feeds it into the roll forming station. 2. Roll Forming Station This is the heart of the machine, featuring a series of rollers that shape the steel into the desired U profile. What sets a changeable machine apart is its ability to adjust the roller configuration easily, allowing for different dimensions without a complete machine overhaul. 3. Cutting Mechanism After the steel has been formed into the U shape, it needs to be cut to the required lengths. The cutting mechanism ensures that each piece is precisely cut, maintaining uniformity and adherence to specifications.

4. Control System Modern machines are equipped with advanced control systems that allow operators to program different sizes and profiles. This automation dramatically reduces the time needed for setup and changeovers.

Advantages of Changeable U Purlin Roll Forming Machines

1. Flexibility The primary advantage of changeable U purlin roll forming machines is their flexibility. Manufacturers can produce a wide range of purlin sizes quickly, responding to varying project needs without extensive retooling.

2. Cost-Efficiency By minimizing production downtime and material waste, these machines significantly enhance cost efficiency. The ability to run shorter production runs without the need for dedicated machinery for each size means companies can be more competitive.

3. Improved Quality Control Automated systems and precise cutting ensure higher levels of consistency and quality in the final products, reducing defects and waste.

4. Versatility in Applications The machine’s capability to produce different profiles makes it suitable for various applications, including residential, commercial, and industrial construction.

5. Reduced Labor Costs Automation and user-friendly interfaces reduce the need for extensive training and manual labor, further lowering operational costs.

Conclusion

In summary, changeable U purlin roll forming machines represent a significant advancement in the manufacturing of structural components. Their ability to adapt to various specifications with efficiency and precision makes them an invaluable asset for manufacturers in the construction industry. As the demand for cost-effective, high-quality building materials continues to rise, these machines will undoubtedly play a pivotal role in shaping the future of construction. With ongoing technological advances, we can expect to see even more innovative features and improvements in these machines, further enhancing their capabilities and applications.