The Evolution and Advantages of Automatic Steel Frame Roll Forming Machines

In the modern construction industry, efficiency and precision are paramount. Among the innovative technologies that have emerged to meet these demands is the automatic steel frame roll forming machine. Specifically designed for the production of components such as studs, tracks, C channels, drywall, main furring, and wall angles, these machines are revolutionizing the way we approach framing in construction projects.

What is an Automatic Steel Frame Roll Forming Machine?

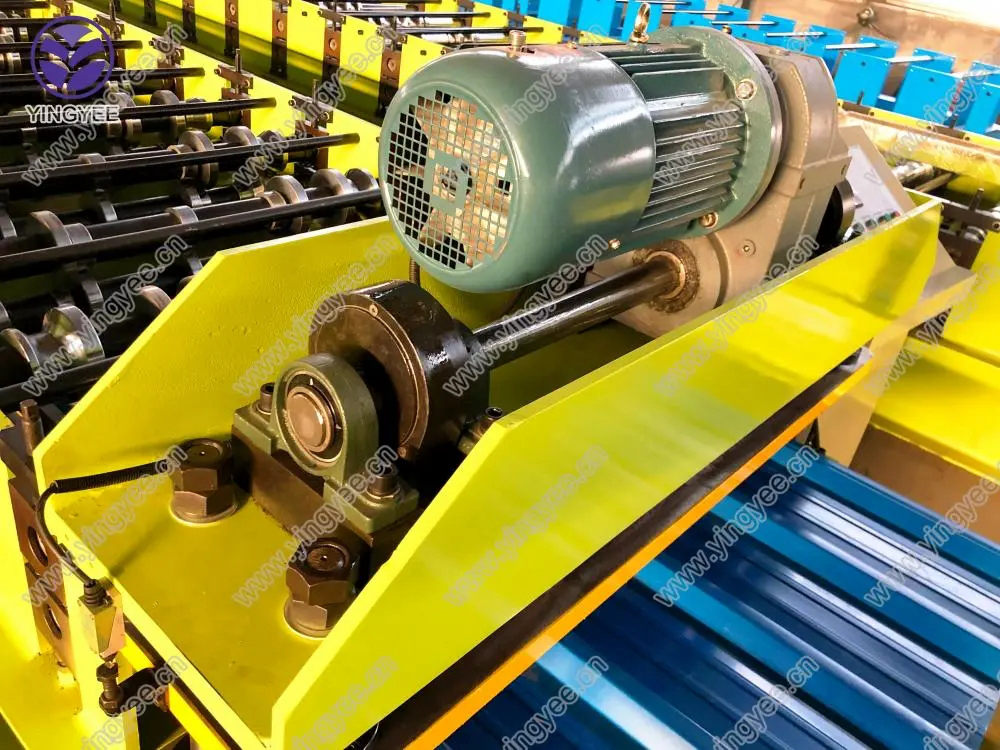

An automatic steel frame roll forming machine is highly specialized equipment that converts flat steel sheets into various structural shapes through a continuous bending process. This machine uses a series of rollers to gradually shape the metal as it passes through, resulting in uniform products that are ready for assembly. The automation aspect significantly reduces manual labor and enhances production speed, making it ideal for large-scale construction projects.

Key Components and Features

The versatility of these machines lies in their ability to produce a wide range of steel components, including

1. Studs and Tracks Essential for creating walls and partitions, steel studs and tracks are lightweight yet robust, providing sufficient support for drywall installations.

3. Drywall Components With the rise in dry construction techniques, machines that can produce specialized drywall profiles are increasingly essential.

4. Main Furring and Wall Angles These elements are key to ensuring the stability and alignment of wall systems, providing the foundation for finishes that complete the building's aesthetic.

Benefits of Using Automatic Roll Forming Machines

1. High Efficiency Automation drastically reduces the time required for fabricating steel profiles. With an automatic feed system and programmable settings, these machines can operate continuously, producing large quantities of components in a fraction of the time compared to traditional methods.

2. Precision and Consistency The roll forming process allows for precise measurements and uniformity in production. Each component is identical, reducing discrepancies that might arise from human error during manual fabrication.

3. Cost-Effective While the initial investment in automatic roll forming machinery can be substantial, the long-term savings from reduced labor costs, minimized waste, and higher output can outweigh these upfront expenses. Consequently, businesses can increase their profit margins by streamlining production processes.

4. Versatility Modern machines offer various customization options, allowing manufacturers to produce different profiles and sizes to meet specific project requirements. This flexibility is crucial in meeting client demands and adapting to changing market conditions.

5. Enhanced Safety Automation reduces the need for human intervention in potentially hazardous work environments. This shift not only helps protect workers' health and safety but also complies with stricter regulatory standards.

Conclusion

The automatic steel frame roll forming machine marks a significant advancement in construction technology, offering numerous benefits that align with the industry's demand for efficiency and precision. By automating the production of key structural components like studs, tracks, C channels, and wall angles, construction professionals can deliver high-quality results while reducing costs and enhancing safety. As the construction industry continues to evolve, embracing innovative solutions such as automatic roll forming machines will be crucial for staying competitive and meeting future challenges. Whether for residential buildings or large-scale commercial projects, the impact of this technology is likely to be profound, shaping the way we build for years to come.