The Evolution and Importance of Automatic Steel Frame Roll Forming Machines

In the construction and building industry, the advancement of technology has significantly transformed traditional methods. One remarkable innovation is the automatic steel frame roll forming machine, specifically designed for producing stud and track C channels, drywall main furring, and wall angles. This article explores the significance of these machines in modern construction, their components, and the benefits they offer.

Understanding Roll Forming Machines

Roll forming is a process used to create shapes by continuously feeding a flat strip of metal through various roll stands. These stands, equipped with tools that mold the steel, transform it into desired profiles such as C channels, track studs, and angles. An automatic roll forming machine enhances this process by automating the tasks, ensuring precision, efficiency, and consistency in the production line.

Key Components of Automatic Steel Frame Roll Forming Machines

1. Material Feeding System The initial step involves a reliable feeding system that accurately positions the steel coil into the machine. This system often features sensors to maintain the correct alignment, allowing for seamless operation without interruptions.

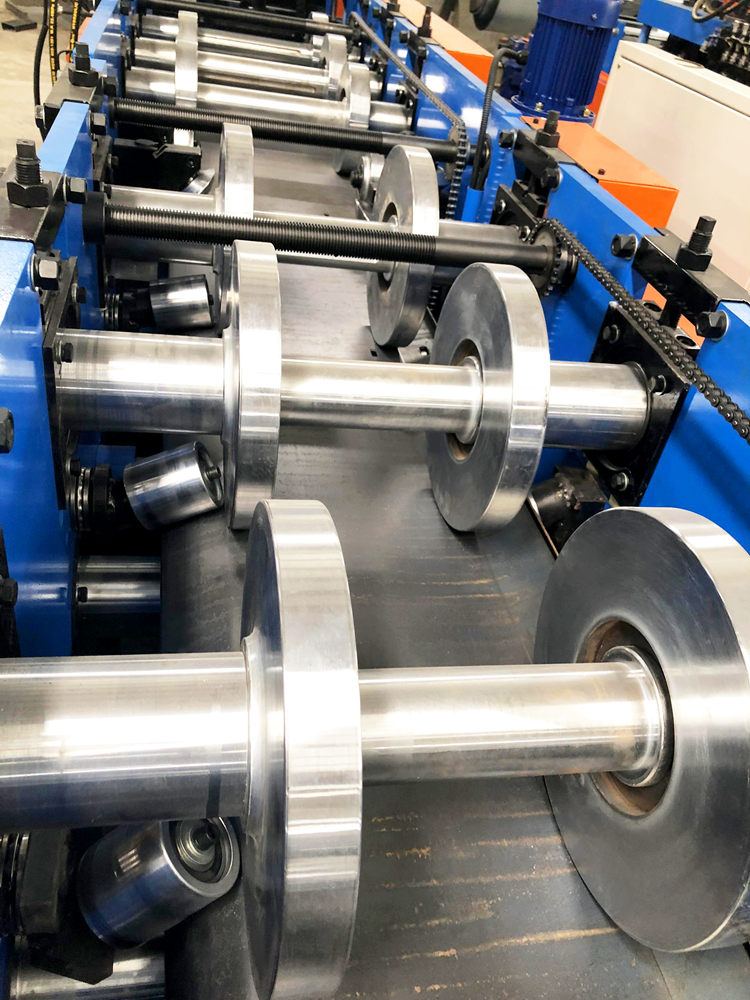

2. Roll Forming Stations The heart of the machine consists of multiple roll forming stations. Each station progressively shapes the steel according to the predefined design specifications. The rollers, often made of hardened steel, are meticulously crafted to withstand wear and ensure quality production.

3. Cutting Mechanism Once the desired profile is formed, the cutting mechanism performs precise cuts at predetermined lengths. This ensures that each piece is uniform, enhancing the overall quality of the final product. Advanced machines often utilize hydraulic or mechanical cutting systems for added efficiency.

4. Control Panel Modern machines are equipped with sophisticated control panels featuring user-friendly interfaces. Operators can easily set parameters such as speed, length, and quantity. Some advanced machines even offer remote monitoring capabilities, allowing for real-time adjustments and analytics.

5. Stacking and Distribution After cutting, the finished products are automatically stacked or distributed via conveyor systems. This automation minimizes manual handling, reducing labor costs and the risk of damage during transportation.

Advantages of Using Automatic Steel Frame Roll Forming Machines

1. Increased Efficiency The automation of the roll forming process accelerates production, allowing manufacturers to meet high-demand requirements without compromising quality. The ability to run the machine continuously maximizes output.

2. Precision and Quality Automatic machines provide consistent results, ensuring that every piece produced adheres to strict design specifications. This precision minimizes waste and enhances the overall quality of construction projects.

3. Cost-Effectiveness Although the initial investment in automatic machinery may be higher than traditional methods, the long-term savings are substantial. Reduced labor costs, minimal material waste, and faster production times contribute to lower overall operational expenses.

4. Versatility Automatic steel frame roll forming machines can be designed to produce various profiles, accommodating different construction needs. This versatility allows businesses to diversify their offerings without requiring multiple machines, optimizing space and resources.

5. Safety Automation reduces the need for manual labor, thereby lowering the risk of accidents in the workplace. With operators spending less time in proximity to moving parts, the overall safety of the work environment improves.

Conclusion

The development of automatic steel frame roll forming machines has revolutionized the way steel framing is approached in the construction industry. By enhancing efficiency, precision, and safety, these machines meet the demands of modern building practices. As the industry continues to evolve, the integration of advanced technology in steel framing will undoubtedly play a crucial role in shaping the future of construction. Investing in such machinery not only positions manufacturers at the forefront of innovation but also aids in the timely delivery of high-quality building materials, vital for successful construction projects.