The versatility and efficiency of an automatic CZ purlin roll forming machine are truly impressive. This equipment has revolutionized the steel construction industry by significantly enhancing the speed and precision of manufacturing purlins, which are critical components in building frameworks. In this article, we delve into the core attributes that underscore this machine's exceptional performance and why it has become an indispensable tool for many construction professionals.

First and foremost, the automatic CZ purlin roll forming machine is engineered with the latest technology that ensures smooth transitions between producing C and Z-shaped purlins. This adaptability is crucial, as it provides the flexibility needed for various building designs and requirements. As an expert in roll forming machinery, it is evident that the seamless switch facilitated by this machine enhances productivity, reduces downtime, and ultimately leads to cost savings—a clear advantage for both manufacturers and end users.

The expertise behind the design of these machines is evident in their construction. They are built from high-grade materials which ensure durability and longevity, even when subjected to the rigorous demands of large-scale production. The precision with which these machines operate can be attributed to advanced computer-controlled settings that guarantee consistent quality and exact specifications. Leveraging expertise in mechanical engineering and computer technology, these machines are a testament to how innovation drives efficiency in production processes.

Authoritativeness is further established by compliance with international manufacturing standards and certifications. Reputable manufacturers ensure that their roll forming machines meet all necessary quality controls, thus instilling confidence among users in various regions worldwide. These certifications not only vouch for the machine's performance but also ensure its safety across diverse operational environments. For professionals seeking reliable and compliant equipment, these attributes highlight why CZ purlin roll forming machines are a preferred choice.

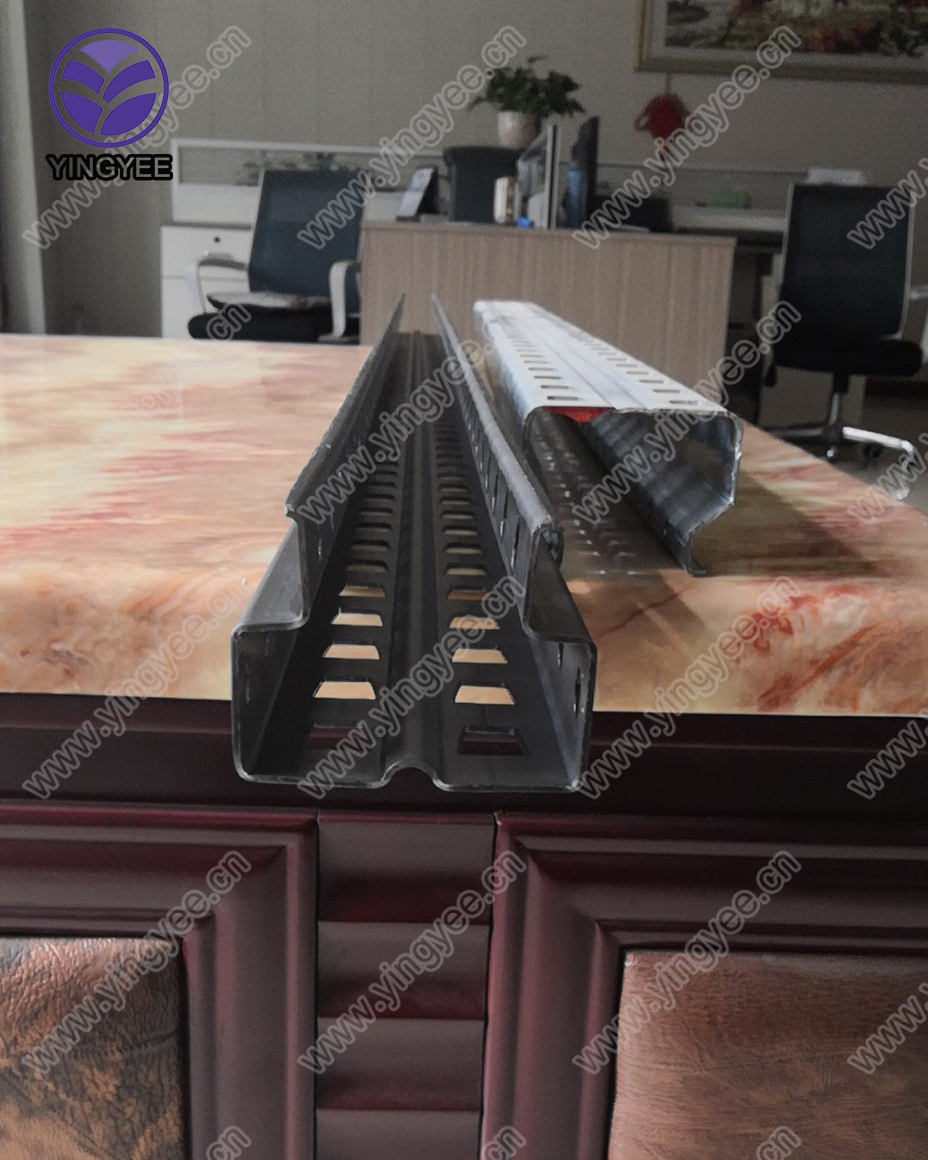

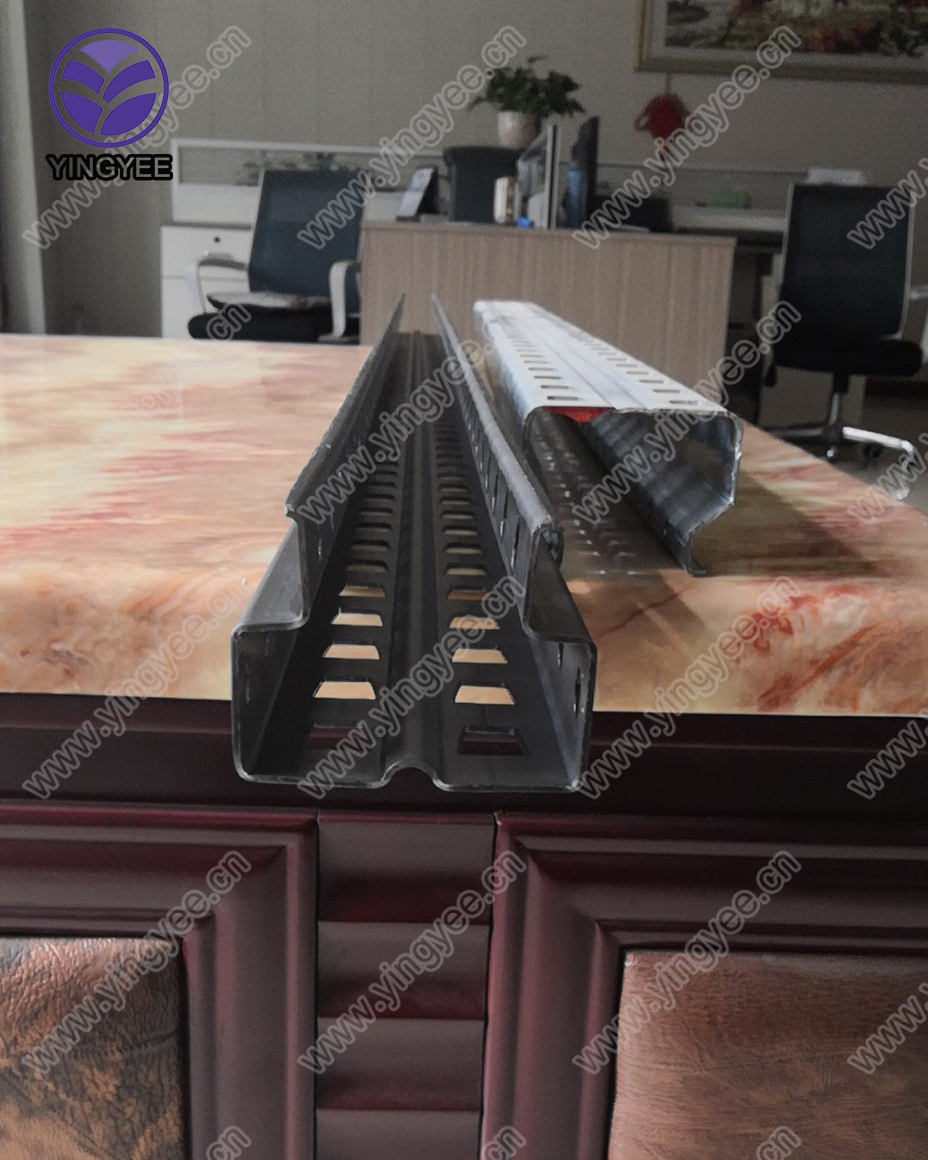

automatic cz purlin roll forming machine

Furthermore, trust in the automatic CZ purlin roll forming machine's performance is reinforced by real-world experiences from numerous satisfied users. Testimonials and case studies highlight how companies have reduced labor costs and minimized material wastage, thanks to the machine’s precision. Additionally, its automated features mean that there is less need for extensive manual oversight, reducing human error and ensuring a consistently high-quality output. For instance, construction firms have reported up to a 30% increase in production efficiency, underscoring the machine's significant impact on operational success.

Maintenance and after-sale services are equally integral to the trustworthiness of these machines. Established manufacturers provide extensive service packages that include regular maintenance and prompt technical support. This ensures the longevity of the machine and assures customers of ongoing support throughout its lifecycle. Having such reliable backup service not only enhances user experience but also strengthens the manufacturer’s reputation as a trusted provider in the machinery market.

Innovation continues to shape the future of the automatic CZ purlin roll forming machine. Manufacturers are actively integrating smarter technologies such as IoT and AI to monitor performance and predict maintenance needs, reducing downtime even further. These advancements are setting new benchmarks for the industry, offering exciting possibilities for increased efficiency and productivity gains.

In conclusion, the automatic CZ purlin roll forming machine stands out as a pinnacle of engineering excellence. Combining expertise, authoritativeness, and trustworthiness, it provides an unparalleled solution for the high-speed, precise, and cost-effective production of structural purlins. For construction professionals seeking to optimize their operations, this machine offers not just a tool but a transformative approach to modern building practices. As it continues to evolve, its impact on the industry promises to grow, ushering in new levels of construction innovation and efficiency.