Angle iron roll forming machines stand as pivotal equipment in the metalworking industry, renowned for their ability to transform flat metal sheets into sturdy, angular profiles with precision. As industry demands for efficient production and customization expand, understanding the nuances of these machines becomes imperative for business growth.

The most salient feature of the angle iron roll forming machine is its exceptional ability to produce consistent, high-quality angle iron profiles. This machinery employs a process where metal sheets are gradually shaped into the desired angle form as they pass through a series of contoured rollers. Each roller gradually alters the metal sheet, reducing the need for excessive manual labor and ensuring a uniform product.

Investing in an angle iron roll forming machine can significantly enhance manufacturing efficiency.

One of the key benefits is the reduction in material waste. By utilizing precise, calibrated roll forming techniques, manufacturers can optimize the amount of raw material used, leading to substantial cost savings. Additionally, the automation capabilities inherent in these machines decrease production time and increase output consistency, thereby allowing companies to meet tight deadlines with confidence.

The automation aspect is crucial, particularly in industries where precision and speed are essential. An angle iron roll forming machine equipped with advanced control systems can seamlessly integrate with existing production lines, providing real-time data on performance and output. This connectivity not only facilitates immediate adjustments to enhance product quality but also aids in predictive maintenance, reducing downtime and extending the machinery's lifespan.

Customization is another significant advantage of angle iron roll forming machines. Manufacturers can automate the production of customized profiles tailored to specific project requirements without sacrificing speed or accuracy. This capability is particularly valuable in sectors such as construction, where custom metal components are often necessary for unique architectural designs.

Professional expertise plays a central role in leveraging the full potential of angle iron roll forming machines. Operators need comprehensive training to understand the nuances of machine settings, maintenance, and troubleshooting. A skilled operator ensures that the machinery functions at optimal efficiency, minimizing the risk of costly errors or production delays. Transitioning from traditional fabrication methods to roll forming requires an understanding of this technology's benefits and challenges, emphasizing the need for skilled labor.

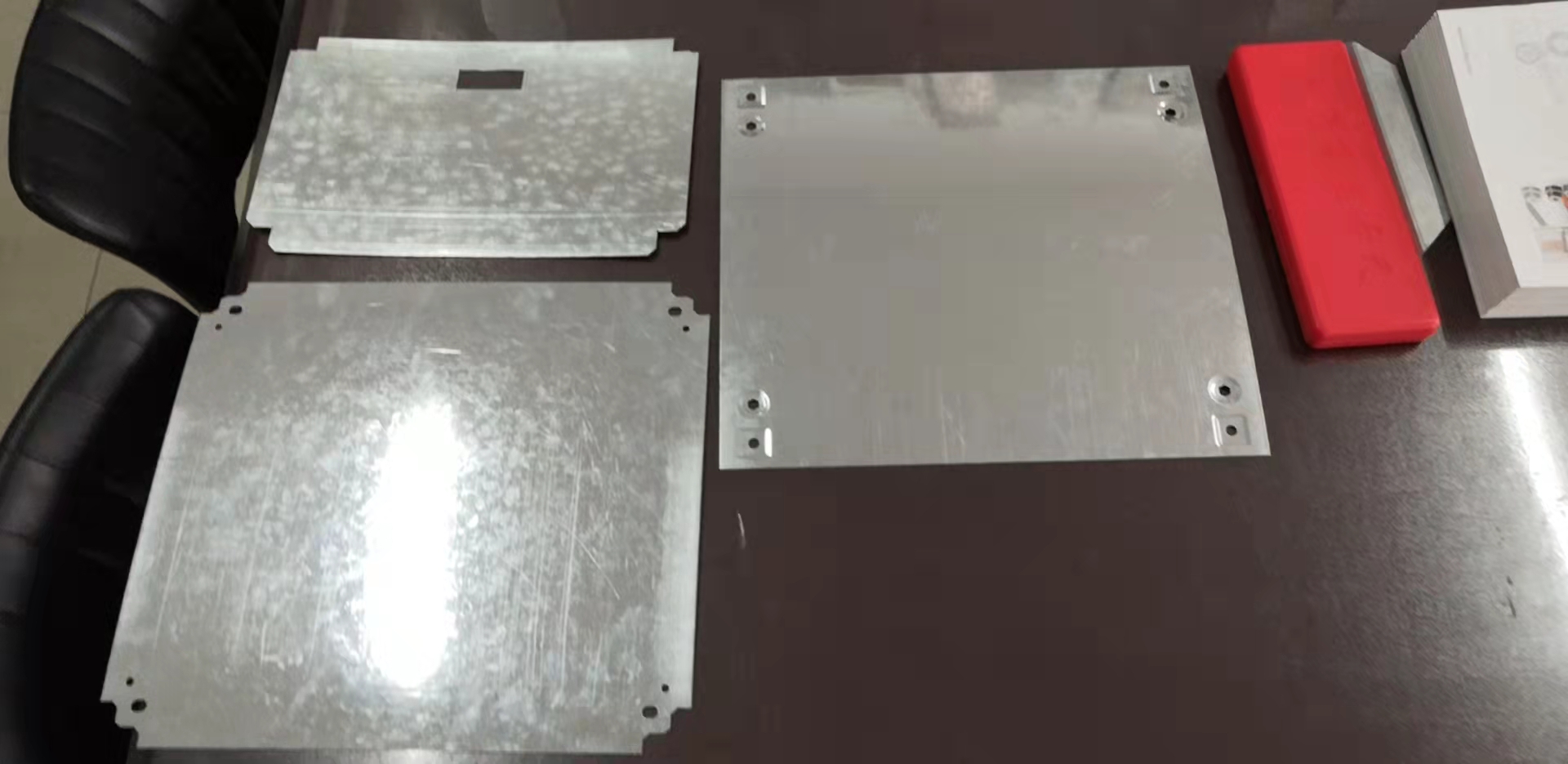

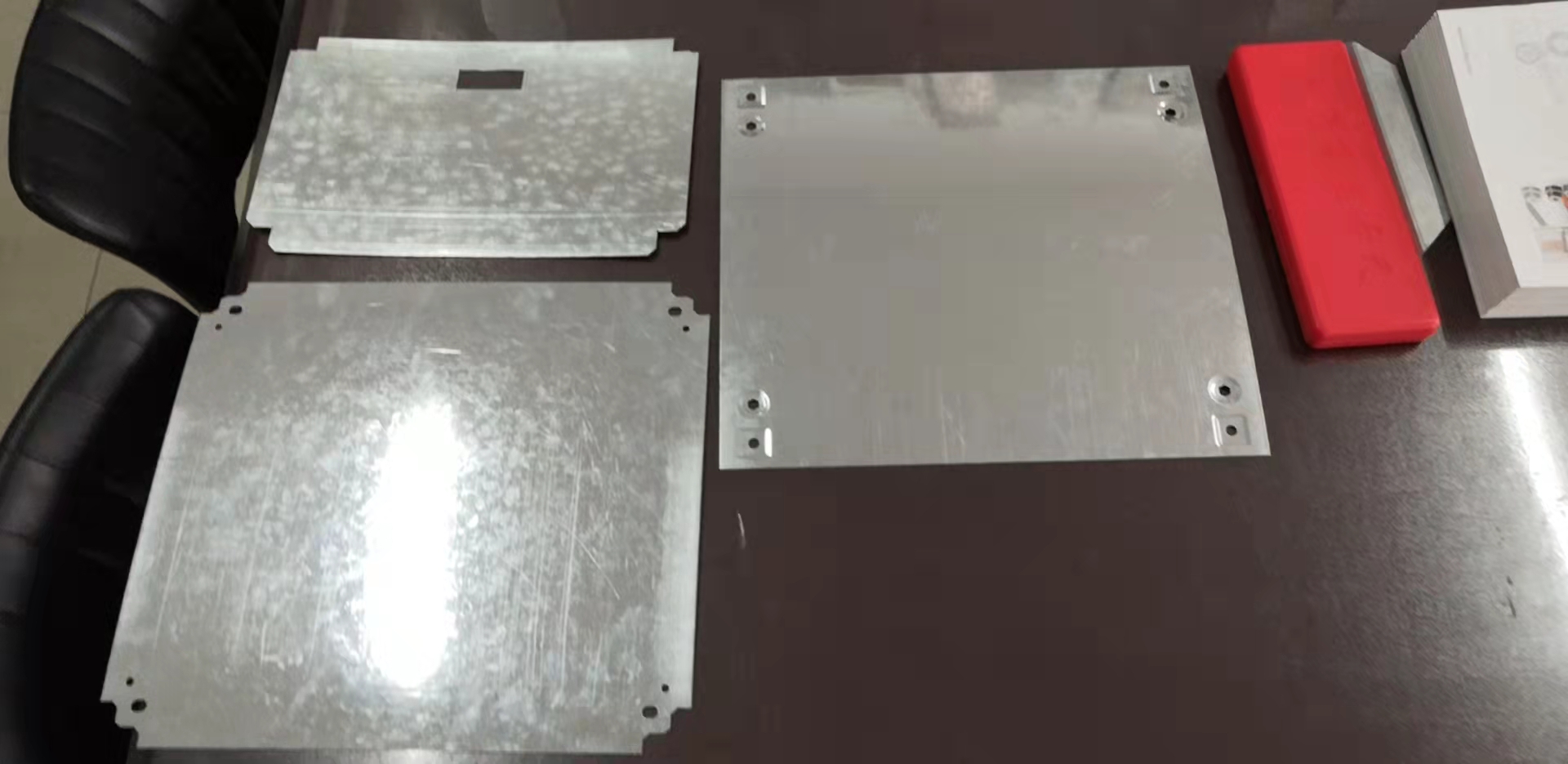

angle iron roll forming machine

When selecting an angle iron roll forming machine, it's essential to consider the manufacturer's reputation and the technology's robustness. Reputable manufacturers invest in research and development, ensuring their machines incorporate the latest advancements in roll forming technology. Such innovations might include better energy efficiency, enhanced safety features, and more user-friendly interfaces.

Trustworthiness is crucial for manufacturers undertaking significant technological investments. Potential buyers should seek testimonials and case studies that demonstrate a machine's performance in real-world applications. Engaging with manufacturers that offer comprehensive support, from installation to after-sale services, can build confidence in the machine’s long-term value and reliability.

The practical applications of angle iron roll forming machines are extensive. Beyond the construction industry, they serve automotive, aerospace, and shipbuilding sectors, where durable, lightweight metal forms are essential. The versatility of applications is a testament to their integral role in modern manufacturing processes.

The rising demand for efficient, high-capacity, and adaptable metal forming equipment solidifies the angle iron roll forming machine's place in industrial settings. Their ability to meet diverse manufacturing needs makes them an invaluable asset, promising a robust return on investment.

Developments in roll forming technology continue to evolve, offering exciting possibilities for future applications. As technology advances, manufacturers can expect even greater precision, broader material compatibility, and faster production speeds.

In conclusion, an angle iron roll forming machine is a cornerstone of modern metal fabrication, embodying efficiency, precision, and versatility. Investing in such a machine equips manufacturers to meet the challenges of today’s fast-paced industrial landscape while ensuring adaptability for future innovations. Through meticulous selection, skilled operation, and a commitment to maintenance, businesses can leverage the full potential of their angle iron roll forming machines, positioning themselves for sustained success in the competitive metalworking market.