The industry of acoustical barrier cold bending machines is an essential part of modern construction and infrastructure projects. These machines are utilized extensively to provide innovative and efficient noise reduction solutions across various environments. With the increasing demand for quieter spaces, understanding the capabilities and benefits of these machines can greatly enhance their integration into engineering and architectural projects.

Acoustical barriers are crucial in today’s noise-polluted world, particularly in urban areas where highways, railways, and industrial activities prevail. The development of the acoustical barrier cold bending machine represents a milestone in noise reduction technology. Unlike traditional processes, this machine allows for precise bends in barrier panels without inducing heat, preserving the integrity and acoustic properties of materials. This rapid and efficient method serves as a significant advancement, opening new possibilities in both design and practical application.

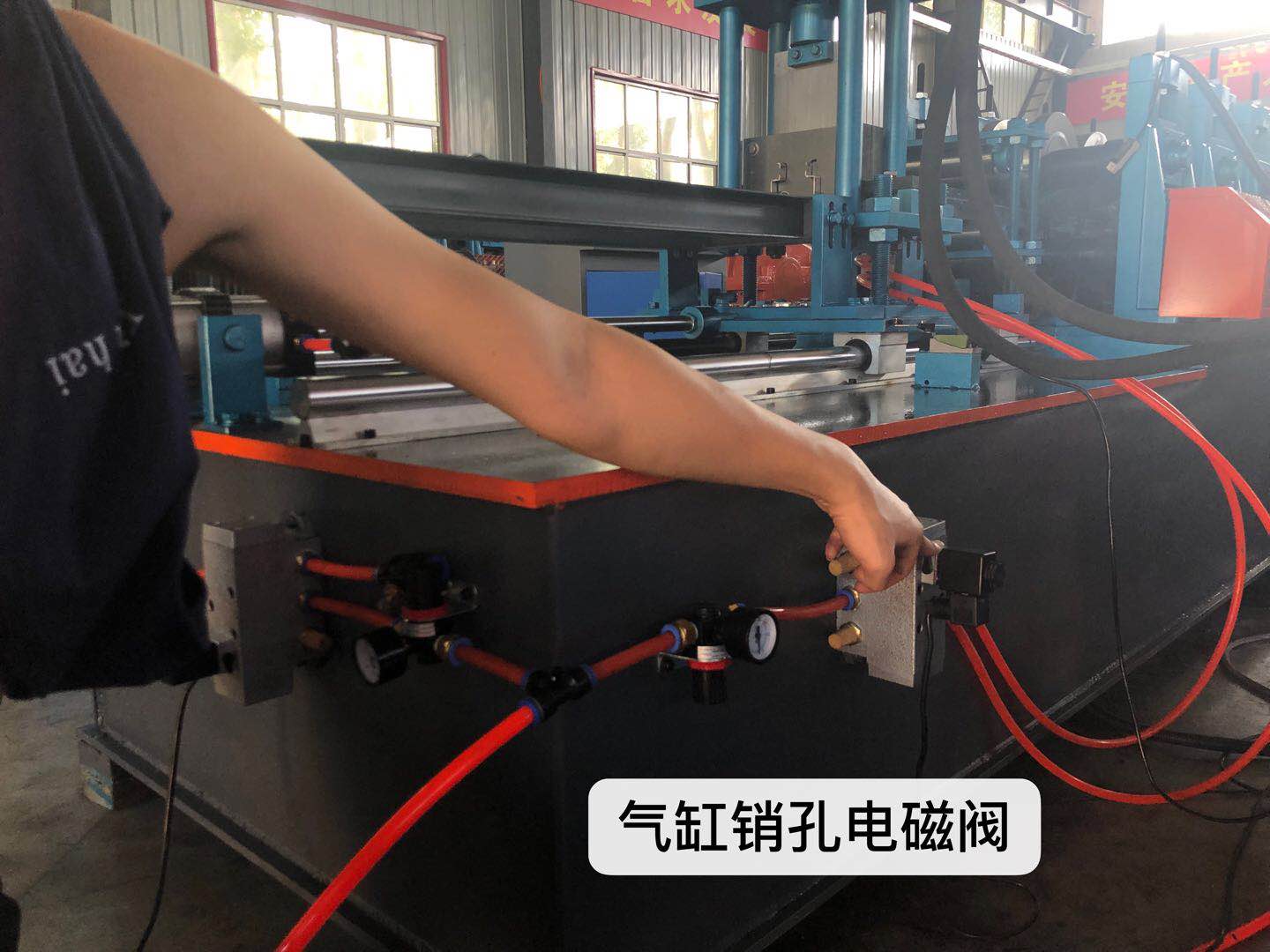

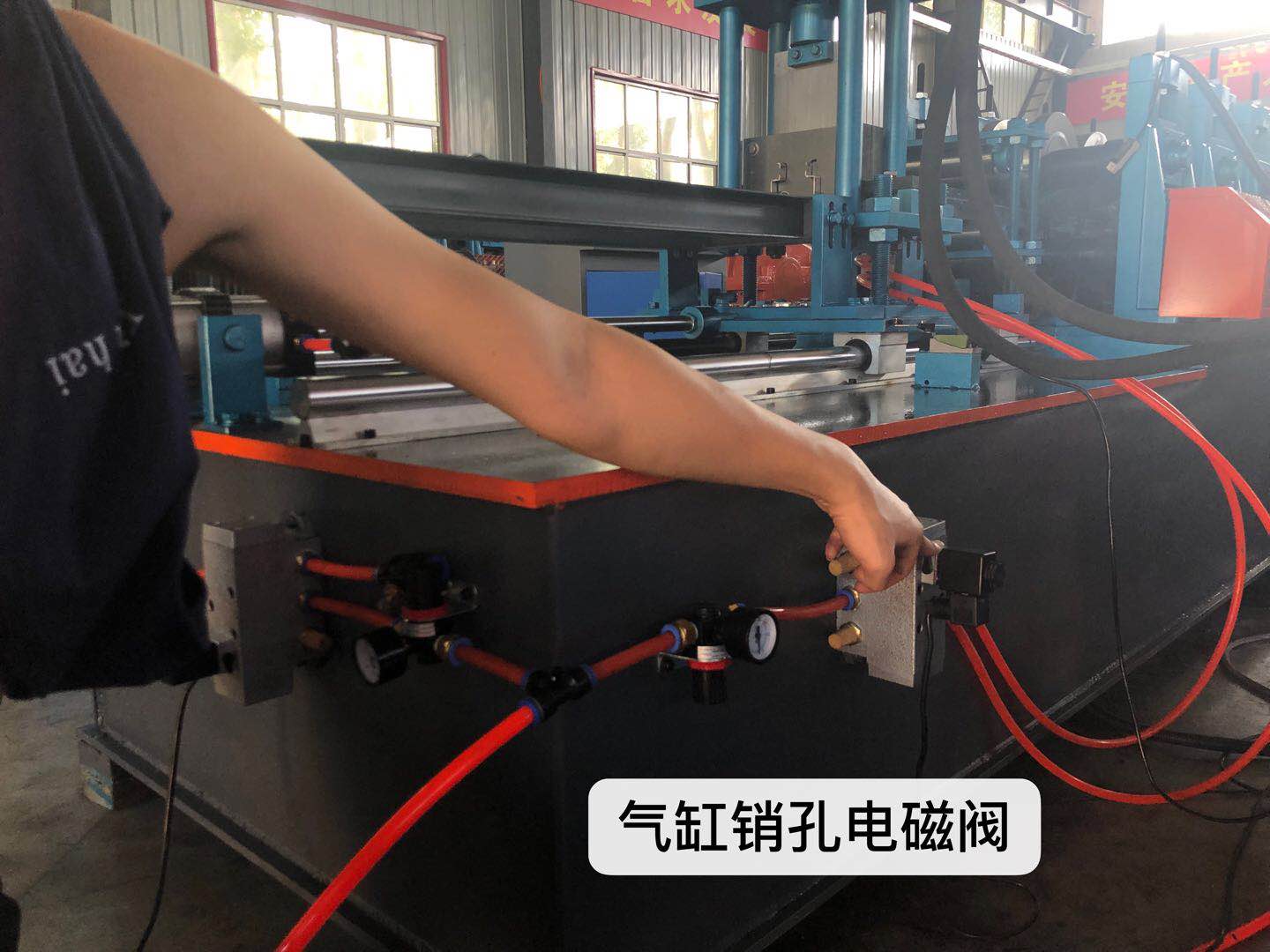

From an expert perspective, the cold bending technology harnesses cutting-edge mechanical engineering principles. By employing intense mechanical pressure rather than heat, these machines maintain the structural integrity and specific acoustical features of the materials. This method ensures that each bend is smooth and uniform, crucial for the performance and aesthetics of acoustic barriers.

Industry professionals recognize that using an acoustical barrier cold bending machine offers incredible versatility. These machines can handle materials such as metal, polycarbonate, and advanced composites, common in manufacturing robust acoustical barriers. Professionals can achieve consistent quality, ensuring that the barriers meet stringent regulatory standards for noise reduction and environmental protection.

The authority of acoustical barrier cold bending machines comes from their application in critical projects across the globe. Infrastructure developers have utilized these machines to deploy noise barriers along extensive rail and motorway networks, enhancing the quality of life for nearby communities. The ability to efficiently produce complex bends and angles allows for custom designs tailored to specific environmental needs, achieving effective sound attenuation while adhering to aesthetic and structural requirements.

acoustical barrier cold bending machine

Trustworthiness is a core component in the adoption of this advanced machinery. Manufacturers prioritize rigorous testing and quality assurance throughout the production process. Each machine undergoes comprehensive evaluations to verify precision, durability, and safety. Additionally, manufacturers often provide extensive training programs for operators and technicians, ensuring a high level of competency in managing these sophisticated machines.

Choosing an acoustical barrier cold bending machine involves understanding both immediate and long-term benefits. In terms of operational efficiency, these machines boast reduced production times and material waste, translating into cost savings for businesses. Environmentally, cold bending is less energy-intensive compared to traditional hot bending methods, aligning with sustainable practices by minimizing carbon footprints.

Furthermore, the machines’ adaptability allows for seamless integration into varied project timelines and scopes. Manufacturers offer customizable options, ensuring each machine meets specific project requirements, whether for urban noise reduction projects or the insulation of industrial sites. The versatility of these machines is a testament to their vital role in the modern advancement of construction and environmental management.

Engaging with acoustical barrier cold bending machines is an investment in quality and innovation. As global standards for acoustic environments become more stringent, businesses equipped with these machines will be poised to deliver superior results. This capability will not only meet but exceed client expectations, reinforcing the company's reputation as a leader in noise management solutions.

In conclusion, acoustical barrier cold bending machines are at the forefront of noise reduction technology. They embody a perfect synthesis of experience, expertise, authority, and trust. By integrating these machines within their projects, businesses are positioned to provide exceptional value, satisfying both immediate needs and setting new benchmarks for future industry standards.