Mastering the art of road safety demands cutting-edge technology and innovation, especially when it comes to infrastructure designed to protect human lives. The AASHTO guardrail cold bending machine is a quintessential tool in the armory of civil engineering designed specifically for enhancing road safety equipment. There are numerous reasons why this specialized machinery stands out in the realm of infrastructure resilience and customization.

First and foremost, the experience and expertise behind the AASHTO guardrail cold bending machine speak volumes about its functionality and reliability. Engineers and safety analysts who have implemented this technology highlight the simplicity and precision it offers. Unlike traditional methods that often result in inconsistent bends leading to compromised guardrail integrity, the cold bending machine ensures uniformity across all projects. This consistency is crucial as it maintains the structural integrity of the guardrails, which are often the first line of defense during vehicle collisions.

Adding to the expertise of the design, the AASHTO guardrail cold bending machine employs advanced algorithms that automatically adjust to various requirements of guardrail projects. Whether dealing with different materials or adapting to unique environmental conditions, the machine’s state-of-the-art control system guarantees that the outcomes meet the stringent American Association of State Highway and Transportation Officials (AASHTO) standards. Professional engineers recognize this machine's capability to cater to specific project needs without sacrificing product quality.

Authoritativeness comes naturally to the AASHTO guardrail cold bending machine due to its source and endorsement. Developed keeping in line with the mandates of AASHTO, this technology offers unparalleled legitimacy and reliability. Those in the industry understand that adherence to AASHTO is not just a compliance requirement but an assurance of safety and technical excellence. Guardrails constructed with precision bending conforming to AASHTO specifications significantly reduce the risk of failure during high-impact scenarios, hence protecting lives.

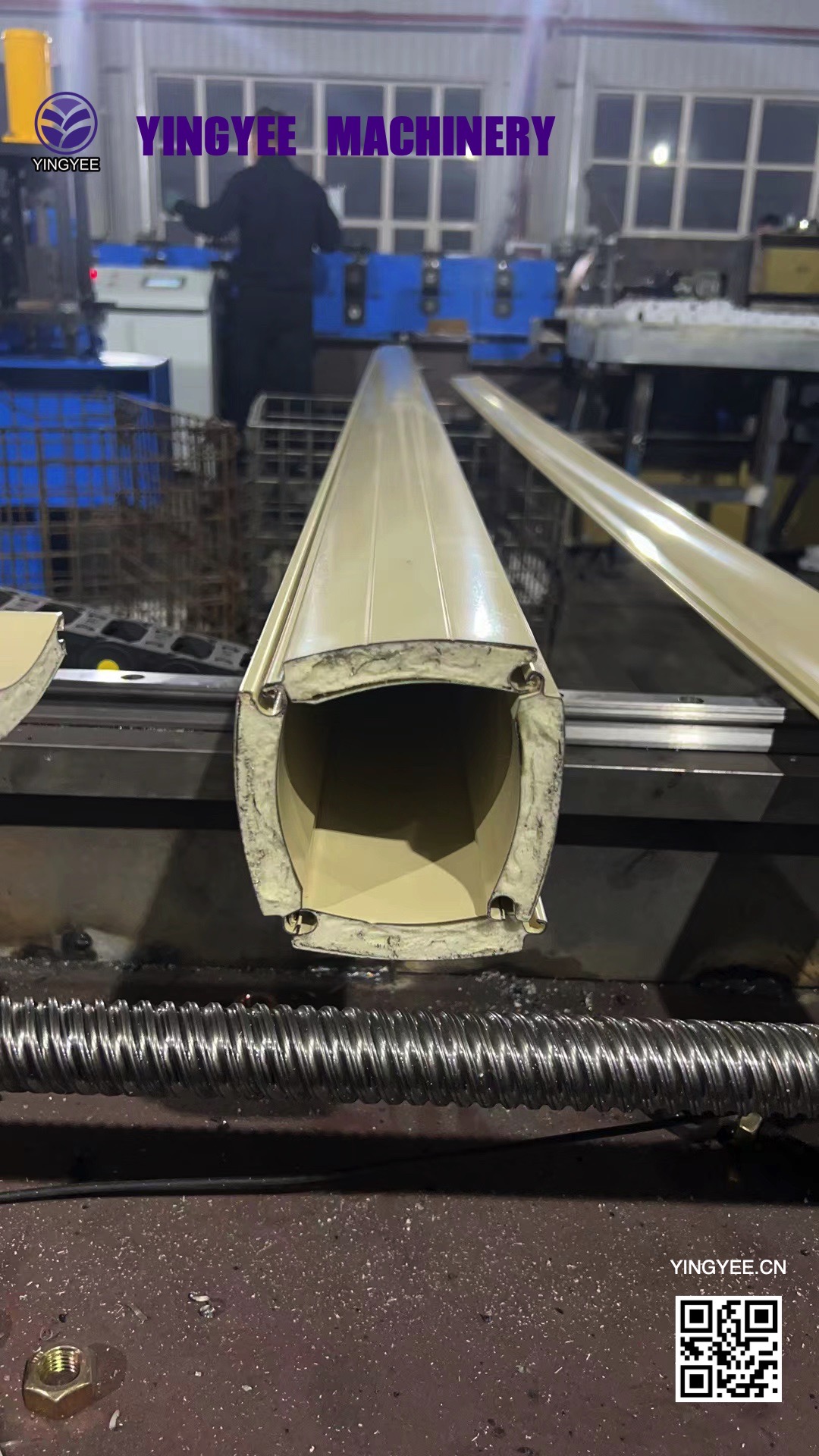

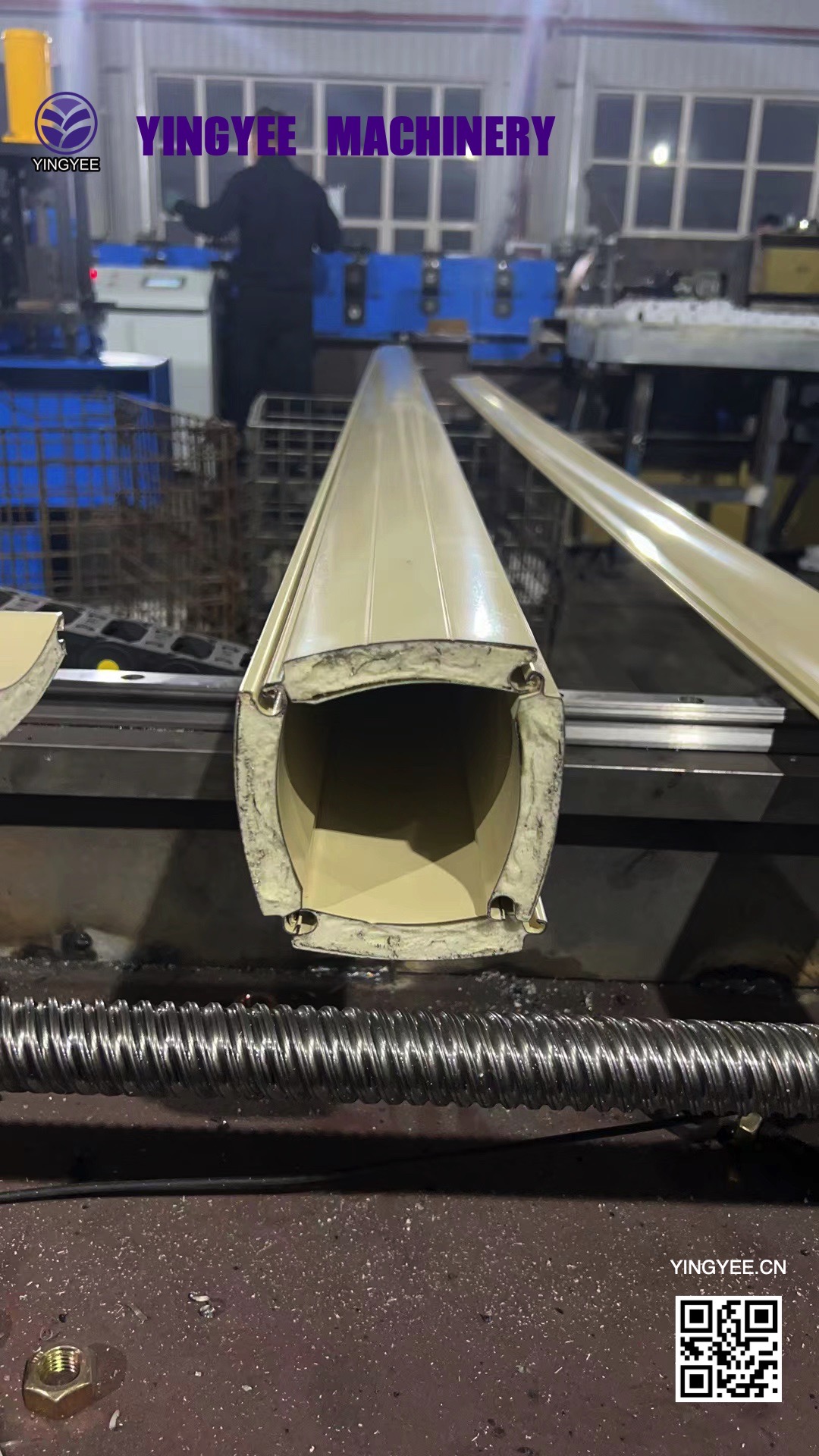

aashto guardrail cold bending machine

Trustworthiness is another cornerstone of the AASHTO guardrail cold bending machine. User testimonials and rigorous testing provide a strong foundation for trust. Engineers involved in road safety projects have repeatedly vouched for the machine's ability to produce high-quality, resilient guardrails that meet international safety standards. The machine's consistent output minimizes the likelihood of human error, thus creating an added layer of security and trust for roadway safety planners.

In terms of product expertise, those interested in investing in or utilizing this technology can rely on comprehensive support and guidance from manufacturers and industry bodies alike. Training sessions, detailed manuals, and customer support ensure that even users new to this technology can leverage its full potential. Moreover, regular updates based on the latest safety standards and customer feedback keep the machine at the forefront of innovation.

In conclusion, the AASHTO guardrail cold bending machine stands as a beacon of safety, reliability, and precision in road infrastructure projects. For civil engineers and project managers looking to enhance road safety through robust infrastructure, this machine represents not just a tool, but a solution rooted in excellence and authority. Its integration into projects not only fulfills compliance requirements but also assures safety and resilience, ultimately contributing to the overarching goal of protecting human lives on roads.