In today's rapidly advancing industrial landscape, cable tray machines have become indispensable, particularly the 50-600 cable tray machine. This sophisticated piece of machinery stands out not just for its versatility and efficiency but also for the edge it provides in structured cabling and infrastructure projects.

The 50-600 cable tray machine serves various sectors, from telecommunications to energy transmission, due to its ability to fabricate cable trays that meet precise project specifications. Its adaptability to produce different sizes and profiles makes it a preferred choice for engineers looking to optimize cable management systems.

One significant advantage of the 50-600 cable tray machine is its precision in manufacturing. By utilizing advanced technology, such as CNC control systems, this machine guarantees that every tray produced adheres to strict quality standards. This precision translates to lower installation errors, ultimately leading to cost savings and increased project efficiency.

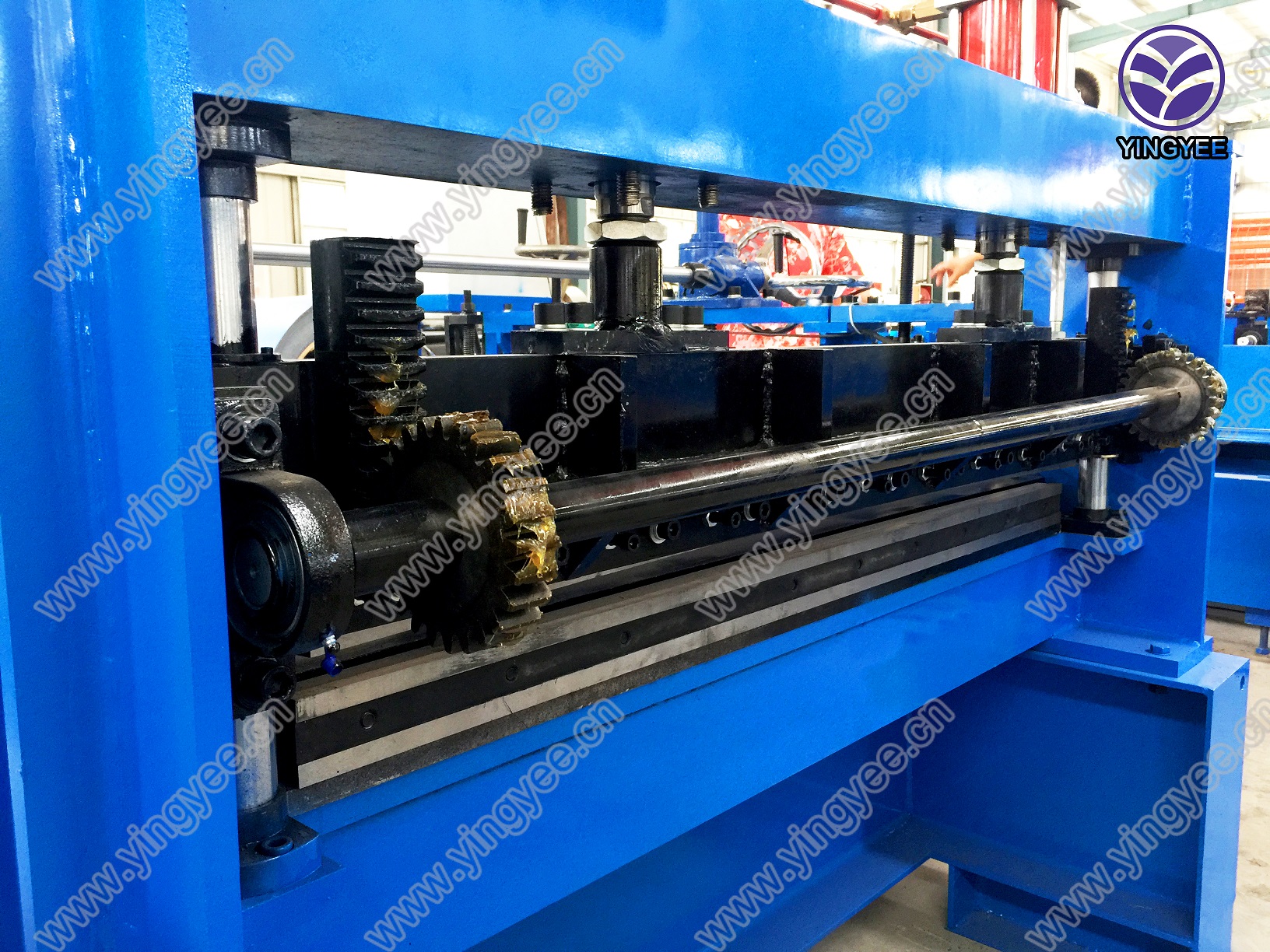

The expertise embedded in the design and operation of this machine cannot be overlooked. Manufacturers and operators require a deep understanding of both the mechanical and software aspects of these systems to ensure high performance. This expertise extends from understanding the mechanical components to mastering the programming required for custom tray designs.

Authoritativeness in the domain of cable tray manufacturing is further exemplified by the machine's compliance with global standards. Whether adhering to NEMA standards in the United States or IEC standards internationally, the 50-600 cable tray machine ensures that each product not only meets but often exceeds compliance benchmarks. This compliance is critical in projects where safety and reliability are paramount, such as in power plants or data centers.

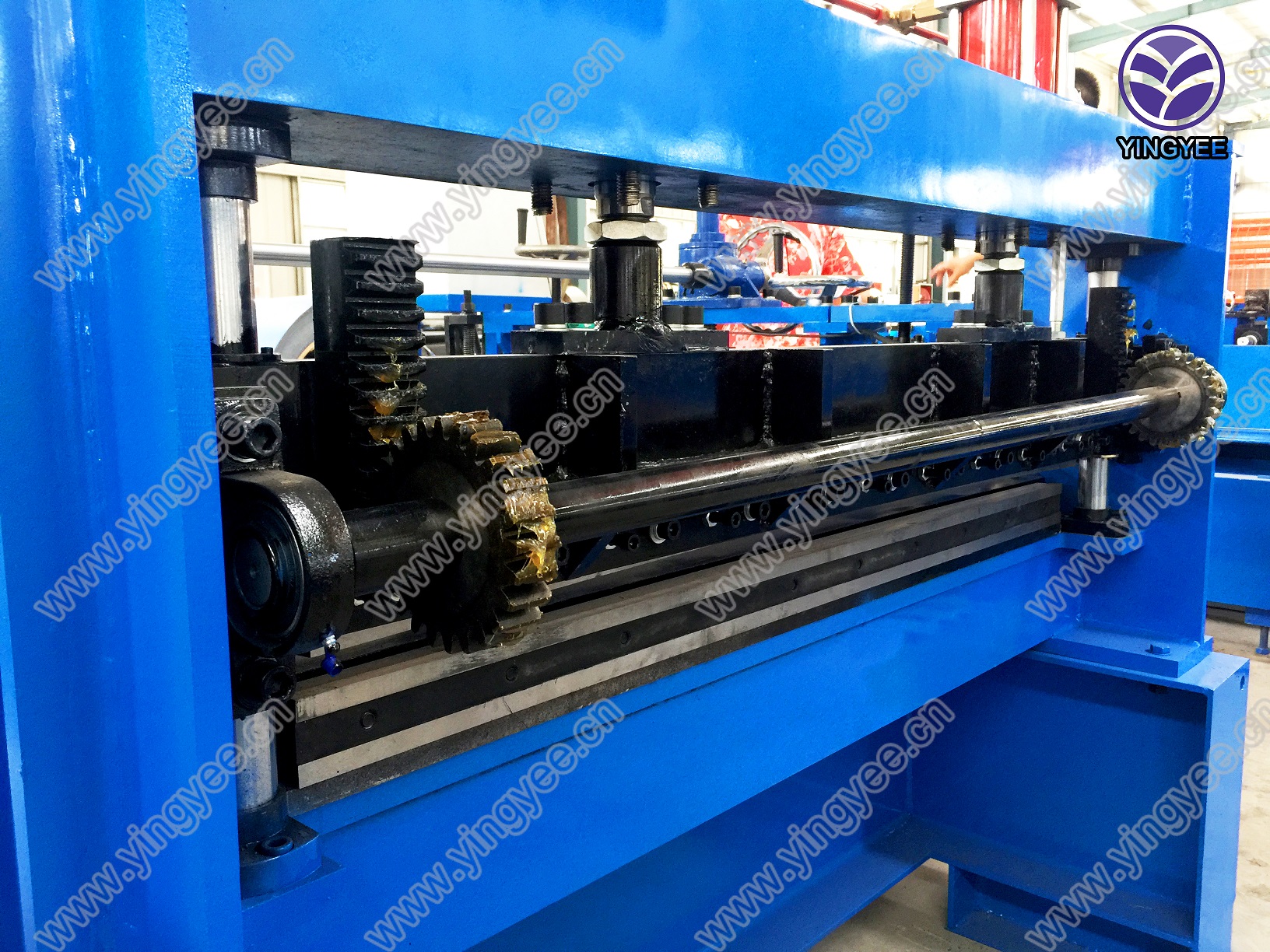

50-600 cable tray machine

Moreover, trustworthiness is interwoven into the very fabric of the 50-600 cable tray machine's production capabilities. Through rigorous testing and quality control measures, manufacturers can deliver machines that consistently perform at high levels. Reliability is key, as any malfunction or inaccuracy can lead to significant operational setbacks. Thus, the trust placed in these machines by industry leaders speaks volumes about their integral role in modern infrastructure projects.

Additionally, the operational experience of using a 50-600 cable tray machine is enhanced by modern user-friendly interfaces that streamline operations while minimizing downtime. These systems often include intuitive control panels, allowing operators to monitor production processes easily and make adjustments on the fly. This not only enhances productivity but also ensures that the quality of products remains uncompromised.

The environmental impact of these machines also bolsters their appeal. Many 50-600 cable tray machines are designed with energy efficiency in mind, reducing the carbon footprint associated with their operation. This aligns with the growing industrial trend of embracing sustainable practices without sacrificing efficiency or quality.

In conclusion, the 50-600 cable tray machine is a cornerstone of modern industrial cabling solutions. Its precision, expertise in production, adherence to global standards, and trustworthy performance make it a top choice for infrastructure projects worldwide. As industries continue to evolve and expand, the role of such innovative machinery will undoubtedly grow, paving the way for more efficient, reliable, and sustainable project outcomes.