Heavy Duty Cable Tray Roll Forming Machine A Comprehensive Overview

In today's fast-paced industrial environment, the need for efficient and reliable cable management solutions has never been more critical. Heavy-duty cable trays are essential for the safe and organized routing of electrical cables in commercial and industrial settings. To meet this growing demand, the heavy-duty cable tray roll forming machine has emerged as an essential piece of equipment in the manufacturing process.

What is a Cable Tray?

A cable tray is a support system designed to hold and route electrical cables and wires. These trays come in various materials, including steel, aluminum, and fiberglass, and are used in a wide range of applications, from manufacturing plants to data centers. Heavy-duty cable trays are specifically designed to support larger volumes of heavier cables, making them suitable for industrial use.

The Importance of Cable Tray Roll Forming Machines

Cable tray roll forming machines play a vital role in the production of cable trays. These machines are capable of creating trays with precise dimensions and consistent quality, ensuring that the final products meet the stringent requirements of modern electrical installations. By utilizing a roll forming process, manufacturers can produce cable trays efficiently, reducing waste and ensuring a high level of accuracy.

Features of Heavy Duty Cable Tray Roll Forming Machine

1. Robust Construction Heavy-duty machines are typically built with high-strength materials to withstand the rigorous demands of industrial application. This ensures durability and long operational life.

2. High Production Speed These machines are designed to operate at high speeds, allowing manufacturers to produce large quantities of cable trays in a short period of time. This is crucial for meeting market demands and deadlines.

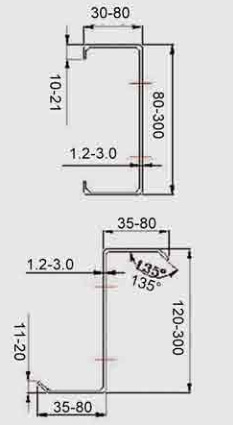

3. Customization Options Many roll forming machines offer customization features, allowing manufacturers to produce cable trays of different shapes and sizes. This flexibility is essential for catering to the varied needs of customers.

4. Automated Control Systems Modern heavy-duty cable tray roll forming machines come equipped with advanced control systems that ensure precision in operation. These systems allow for easy adjustments and monitoring of the forming process.

5. Efficiency and Waste Reduction Through the optimized design of the forming process, these machines can minimize material waste. This not only reduces costs but also contributes to more sustainable manufacturing practices.

Applications of Heavy Duty Cable Trays

Heavy-duty cable trays produced by roll forming machines are utilized in numerous applications, including

- Industrial Facilities In factories and production plants, cable trays help organize power and control cables, ensuring safety and accessibility.

- Data Centers With the growing need for data processing, cable trays are crucial in managing the extensive cabling used in data centers.

- Commercial Buildings For large commercial enterprises, cable trays provide an effective solution for routing telecommunications and electrical cabling across expansive areas.

- Infrastructure Projects In construction and infrastructure projects, cable trays are often required to manage the complex network of electrical systems.

Benefits of Using a Roll Forming Machine for Cable Trays

Investing in a heavy-duty cable tray roll forming machine offers several advantages

- Cost Efficiency By producing cable trays in-house, manufacturers can significantly reduce costs associated with third-party procurement.

- Quality Control In-house production allows for better quality control, as manufacturers can monitor every stage of the forming process.

- Faster Turnaround Times With the capability to produce trays quickly, manufacturers can fulfill urgent orders without delay.

Conclusion

The heavy-duty cable tray roll forming machine represents a vital component of the modern manufacturing landscape. By facilitating the efficient production of high-quality cable trays, these machines help businesses meet the growing needs of electrical and infrastructure markets. As industries continue to evolve, the importance of such advanced manufacturing solutions will only increase, ensuring that cable management remains organized and efficient. Investing in heavy-duty cable tray roll forming technology is, therefore, a strategic move for manufacturers aiming to enhance productivity and maintain competitiveness in a dynamic market.