The Evolution and Benefits of Automatic Grid Roll Forming Machines

In the modern manufacturing landscape, efficiency and precision are paramount. One of the key advancements in metal processing technology is the automatic grid roll forming machine. These machines have revolutionized the way metal components are produced, particularly in the manufacture of grids used in various applications, such as ceilings, partitions, and decorative elements. This article delves into the workings, benefits, and future of automatic grid roll forming machines.

Understanding Automatic Grid Roll Forming Machines

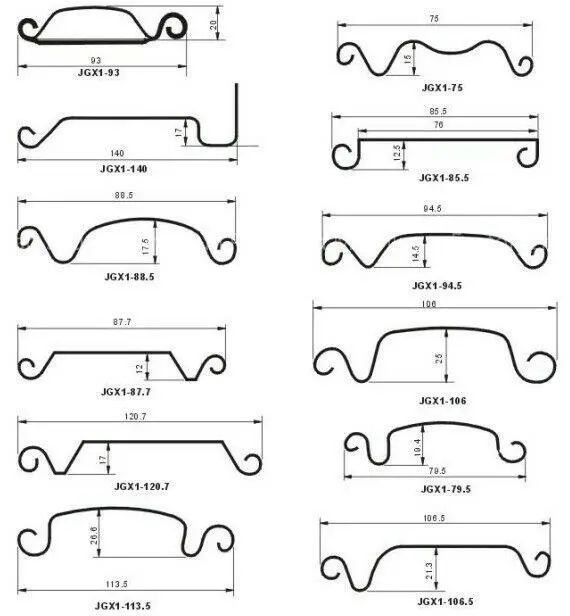

Automatic grid roll forming machines are specialized equipment designed to transform metal coils into structured grids through a series of roll-forming processes. The machine consists of multiple rollers that shape the metal progressively, starting from a flat coil and gradually forming it into a grid pattern. The automation aspect allows operators to set specific parameters such as the width, height, and spacing of the grid, leading to consistent production and reduced manual handling.

The design of these machines caters not only to high-volume production but also to versatility. Modern machines can handle a variety of materials, including galvanized steel, aluminum, and stainless steel, making them suitable for various industries. Additionally, with enhanced computer controls, adjustments can be made quickly without extensive downtime, allowing for rapid transitions between different product specifications.

Benefits of Using Automatic Grid Roll Forming Machines

1. Increased Efficiency Automated processes significantly reduce production time. These machines can produce grids at a much faster rate than traditional methods, ensuring that manufacturers meet high demand without compromising on quality.

2. Consistency and Precision The automated nature of these machines ensures uniformity in the dimensions of the grids produced. This uniformity is crucial for applications where precise fitting is necessary, such as in commercial construction and interior design.

3. Labor Savings With automation, fewer operators are needed to run the production line, reducing labor costs and minimizing the risk of human error. This shift not only improves operational efficiency but also enhances workplace safety by reducing manual handling.

4. Flexibility in Design Automatic grid roll forming machines are capable of producing custom designs based on client specifications. This flexibility allows manufacturers to cater to specific customer needs, which is essential in competitive markets.

5. Waste Reduction Advanced roll forming techniques and customized setups help minimize material waste. This contributes to more sustainable manufacturing practices and lowers overall production costs.

The Future of Automatic Grid Roll Forming Machines

As technology continues to advance, the future of automatic grid roll forming machines appears promising. With developments in Industry 4.0 concepts, we can expect even more sophisticated machines equipped with IoT capabilities. This connectivity will enable real-time monitoring, predictive maintenance, and data analytics, further streamlining the manufacturing process.

Moreover, the integration of artificial intelligence could lead to smarter machines that can adjust settings autonomously based on production demands and material behavior, enhancing efficiency and reducing downtime.

In conclusion, automatic grid roll forming machines represent a remarkable stride in manufacturing technology. Their efficiency, precision, and adaptability make them invaluable tools in various industries. As technology evolves, we can anticipate even greater innovations that will further optimize their performance, solidifying their place in the future of metal fabrication. As manufacturers increasingly focus on sustainable practices and enhanced productivity, these machines will undoubtedly play a crucial role in shaping the manufacturing landscape for years to come.