Understanding Wall Angle Light Keel Forming Machines An Overview

In recent years, the construction and manufacturing industries have witnessed significant advancements, particularly in the production of lightweight, durable building materials. One such innovation that has gained prominence is the wall angle light keel forming machine. This specialized equipment plays a crucial role in the fabrication of metal keels used in drywall installations, ceiling applications, and partition walls. Understanding the functionalities, advantages, and applications of these machines can help industry professionals make informed decisions.

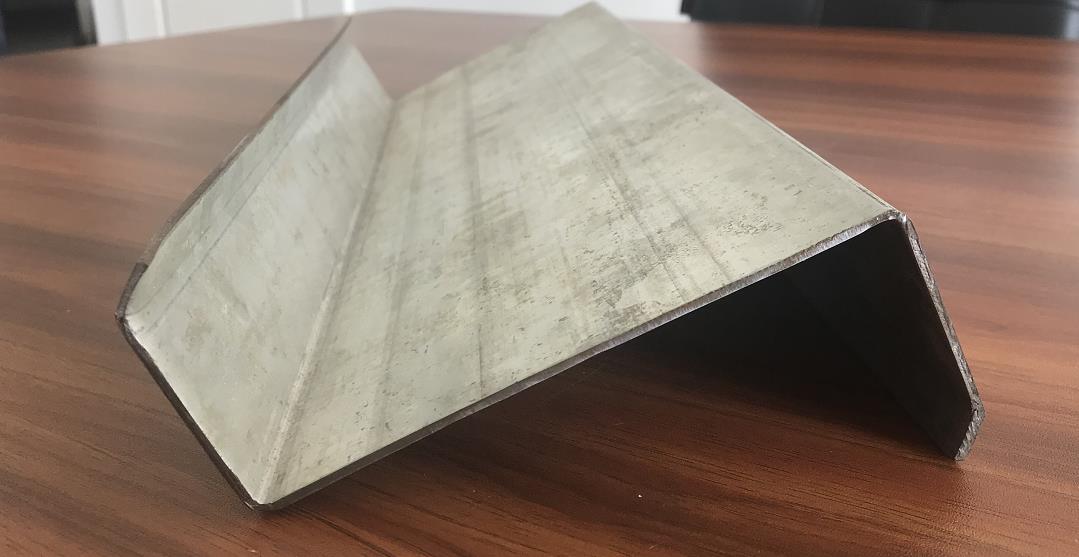

At the core of any wall angle light keel forming machine is its ability to transform raw metal coils into precisely engineered light keels. These machines employ advanced forming technology, which involves bending, cutting, and shaping metal sheets into specific profiles. The seamless integration of high-quality components, including rollers and cutters, ensures that the final product meets stringent industry standards. The flexibility of these machines allows them to be adjusted for various keel sizes and shapes, accommodating the demands of different projects.

One of the most significant advantages of using a wall angle light keel forming machine is the efficiency it brings to the manufacturing process. Traditional methods of producing metal keels often involve manual labor, which can be time-consuming and prone to errors. In contrast, automated forming machines streamline the production workflow, drastically reducing both time and cost. This efficiency not only enhances productivity but also improves consistency in the quality of the finished product.

Another notable benefit is the machine’s versatility. Wall angle light keel forming machines can handle various materials, including galvanized steel, aluminum, and other metal alloys. This capability makes them suitable for a wide range of applications, from residential constructions to commercial projects. Moreover, the machines can produce different types of keels, such as C-shaped, U-shaped, and L-shaped profiles, thus fulfilling diverse design requirements.

In addition to efficiency and versatility, wall angle light keel forming machines are also known for their durability and low maintenance requirements. Built with robust materials and innovative engineering techniques, these machines are designed to withstand the rigors of continuous operation in industrial settings. Routine maintenance practices are simple and can be carried out quickly, ensuring minimal downtime and optimal production levels.

The market for wall angle light keel forming machines is expanding as the demand for lightweight and sustainable building materials grows. With the global push towards energy efficiency and environmentally friendly construction practices, these machines contribute to the production of materials that aid in achieving better insulation and reduced energy consumption in buildings.

Furthermore, advancements in technology have led to the integration of computer numerical control (CNC) systems in many modern machines. CNC technology enhances precision, allowing for intricate and custom designs that were previously unattainable through manual methods. Operators can program the machine for different designs, resulting in a highly efficient setup with minimal waste.

In conclusion, wall angle light keel forming machines are indispensable tools in the construction industry, offering a blend of efficiency, versatility, and durability. Their ability to produce high-quality light keels quickly and cost-effectively positions them as a valuable asset for manufacturers and contractors alike. As the industry continues to evolve, embracing innovations in machinery will be essential in meeting the growing needs for efficient and sustainable construction solutions.