Ọnọdụ mmepụta ihe bụ isi nke akụrụngwa

Ọnọdụ mmepụta akụrụngwa:

1 The equipment covers an area: 30×3×2 (length×width×height) meters.

2 Ntuziaka nri akụrụngwa: aka ekpe na aka nri pụọ.

3 voltaji oke 380, 50Hz, 3 nkeji.

4 Air source: the flow rate is 0.5m³/Min; the pressure is 0.7MPa.

5 Mmanụ hydraulic: 46# mmanụ hydraulic.

6 Gear mmanụ: 18 # mmanụ hyperbolic gear.

Isi teknuzu paramita nke akụrụngwa

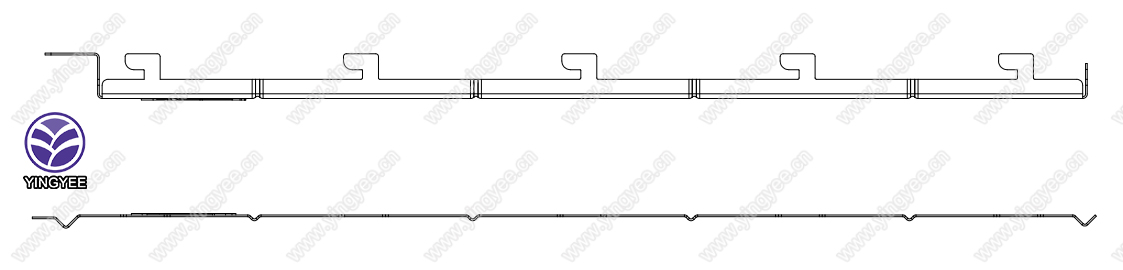

1 Rolled strip width: ≤775mm

2 Mpempe akwụkwọ mpịakọta: 0.6mm / 0.9mm

3 Rolled strip material: cold-rolled steel strip yield limit σs≤260Mpa

4 Roll material: Cr12, quenched HRC56°-60°

5 ịkpụzi ọsọ: 0 ~ 12m / min, online ọsọ 0-6 M / min

Ogologo workpiece 6 akpọrepu: ntọala efu nke onye ọrụ

7 ngụkọta arụnyere ike nke akụrụngwa: banyere 30KW.

Na-ahazi:

eserese:

Isi nkọwapụta

|

Mba. |

Ihe |

Nkọwa: |

|

1 |

Ihe onwunwe |

1. Thickness: 0.6mm 2. Input width: max. 462mm 3. material: Cold rolled steel strip; yield limit σs≤260Mpa |

|

2 |

Power supply |

380V, 60Hz, 3 phase |

|

3 |

Capacity of power |

1. Total power: about 20kW 2. Punchine system power: 7.5kw 3. Roll forming machine power: 5.5kw 4. Track cutting machine power: 5kw |

|

4 |

Ọsọ |

Ọsọ ahịrị: 0-9m/min (gụnyere ịkụ ọkpọ) Ọsọ nhazi: 0-12m/min |

|

5 |

Mmanụ hydraulic |

46# |

|

6 |

Gear Mmanụ |

18# Hyperbolic gear oil |

|

7 |

Akụkụ |

Approx.(L*W*H) 20m×2m×2m |

|

8 |

Nkwụsị nke rollers |

Roll forming machine for Fundo 2F: 17 rollers Otu ihe mkpuchi mkpuchi makado 1F: 12 rollers |

|

9 |

Ihe nke rollers |

Cr12, quenched HRC56°-60° |

|

10 |

Ogologo nke ihe eji arụ ọrụ akpọrepu |

Ntọala efu nke onye ọrụ |

|

11 |

Bee ụdị |

Hydraulic Tracking cut |