(h beam welding)

H beam welding forms the backbone of structural steel fabrication, with global demand projected to grow at 4.8% CAGR through 2030 according to Market Research Future. This specialized welding process combines precision arc welding with automated material handling to create I-shaped structural components essential for commercial construction (accounting for 62% of applications), industrial machinery (28%), and infrastructure projects.

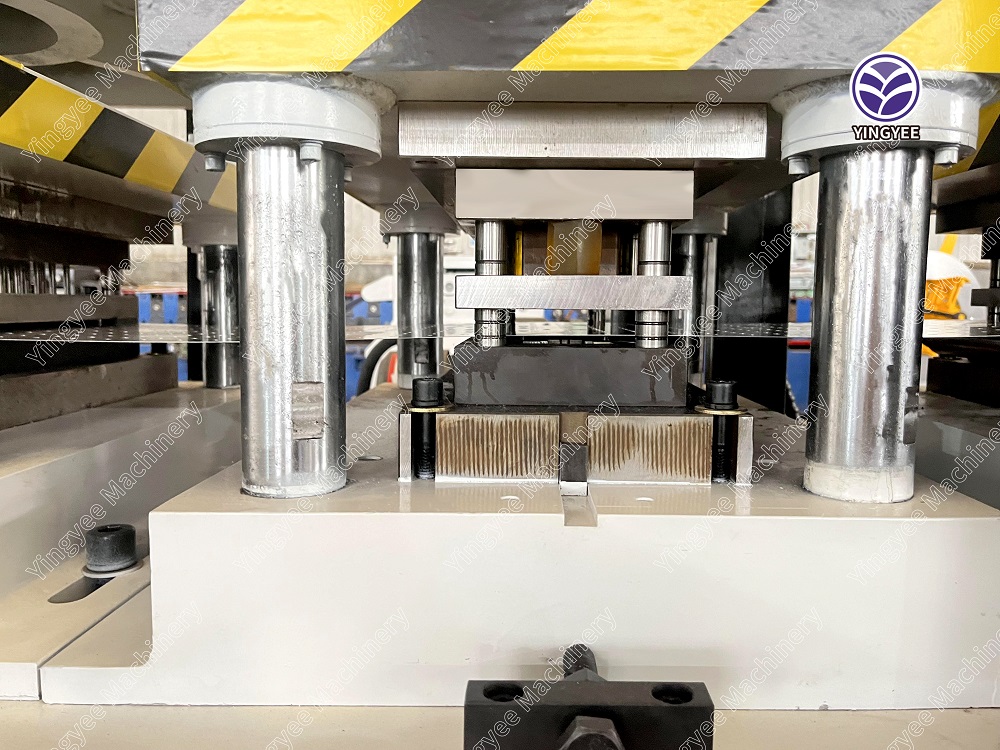

Advanced H beam welding machines now achieve deposition rates exceeding 45 kg/h while maintaining ±0.3mm dimensional accuracy. Proprietary waveform control technology reduces energy consumption by 18-22% compared to conventional models, with dual-wire systems enabling 2.1x faster production speeds for heavy 400-800mm flange assemblies.

| Feature | Standard Models | Premium Models | Industrial Custom |

|---|---|---|---|

| Welding Speed | 0.8-1.2 m/min | 1.5-2.4 m/min | 3.0-4.5 m/min |

| Positional Accuracy | ±1.5mm | ±0.8mm | ±0.3mm |

| Power Efficiency | 82-85% | 89-92% | 94-96% |

The global market features over 120 certified manufacturers, with top-tier suppliers demonstrating distinct operational advantages:

Base model pricing starts at $48,000 for manual systems, while fully automated lines range from $220,000 to $850,000 depending on configuration. ROI analysis shows 14-18 month payback periods for high-utilization operations through 34-41% scrap reduction and 29% labor cost savings.

Modern systems adapt to specific production requirements through modular components:

A 2023 implementation for bridge component fabrication achieved:

Emerging technologies like AI-powered parameter optimization and hybrid laser-arc systems are redefining production benchmarks. Early adopters report 19-23% improvements in material utilization and 41% faster changeover times, positioning H beam welding automation as critical infrastructure for next-generation metal construction projects.

(h beam welding)

A: H beam welding machine price depends on automation level, material thickness capacity, and brand reputation. Advanced features like CNC controls or dual-wire systems increase costs. Bulk purchases from manufacturers may offer discounts.

A: Verify certifications like ISO and CE compliance. Evaluate manufacturers' industry experience and client testimonials. Prioritize suppliers offering comprehensive after-sales support and warranty terms.

A: Automatic beam welding lines boost productivity through continuous operation and reduced manual intervention. They ensure consistent weld quality with precision programming. Energy-efficient models can lower long-term operational costs.

A: Yes, most modern H beam welding machines support various steel grades including carbon and alloy steels. Compatibility depends on the machine's power output and torch specifications. Consult manufacturers for specific material requirements.

A: Regular lubrication of mechanical components and nozzle cleaning are essential. Software updates and sensor calibration maintain precision. Manufacturers typically provide customized maintenance schedules based on usage intensity.