Investing in a downspout roll forming machine can significantly enhance your manufacturing capabilities, allowing for precise, efficient, and scalable production of downspouts. With the increasing demand for high-quality gutter systems in the construction industry, owning such a machine not only gives you a competitive edge but also reassures clients of your commitment to quality and innovation.

Real-world experiences shared by industry experts reveal that integrating a downspout roll forming machine into your production line reduces manual labor, minimizes errors, and boosts output. For businesses looking to streamline operations, this equipment bridges the gap between traditional manufacturing methods and modern technology-driven processes. With user-friendly interfaces and automated solutions, these machines adjust to varying production specifications, tailoring output to specific project needs and ensuring consistency in product quality.

The expertise embedded in the design and functionality of downspout roll forming machines is evident in their capacity to handle diverse materials, including aluminum, copper, and galvanized steel. This versatility not only broadens the range of products you can offer but also attracts a more extensive customer base. Thanks to advanced engineering, these machines ensure that even complex profiles are manufactured smoothly, avoiding material wastage and enhancing the sustainability aspect of your operations.

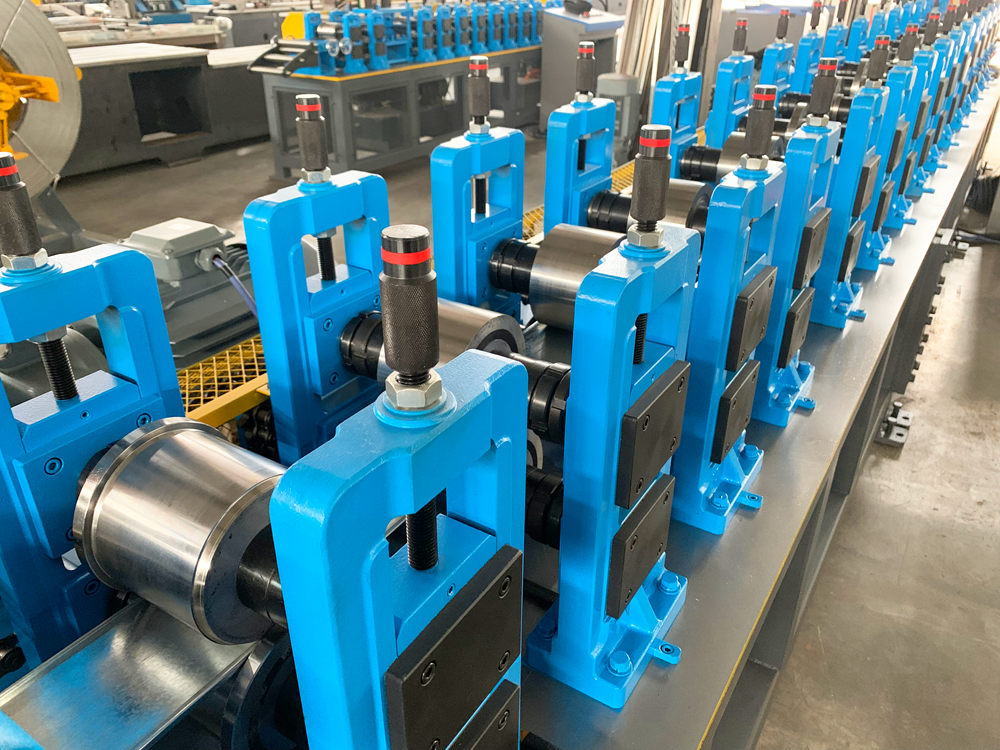

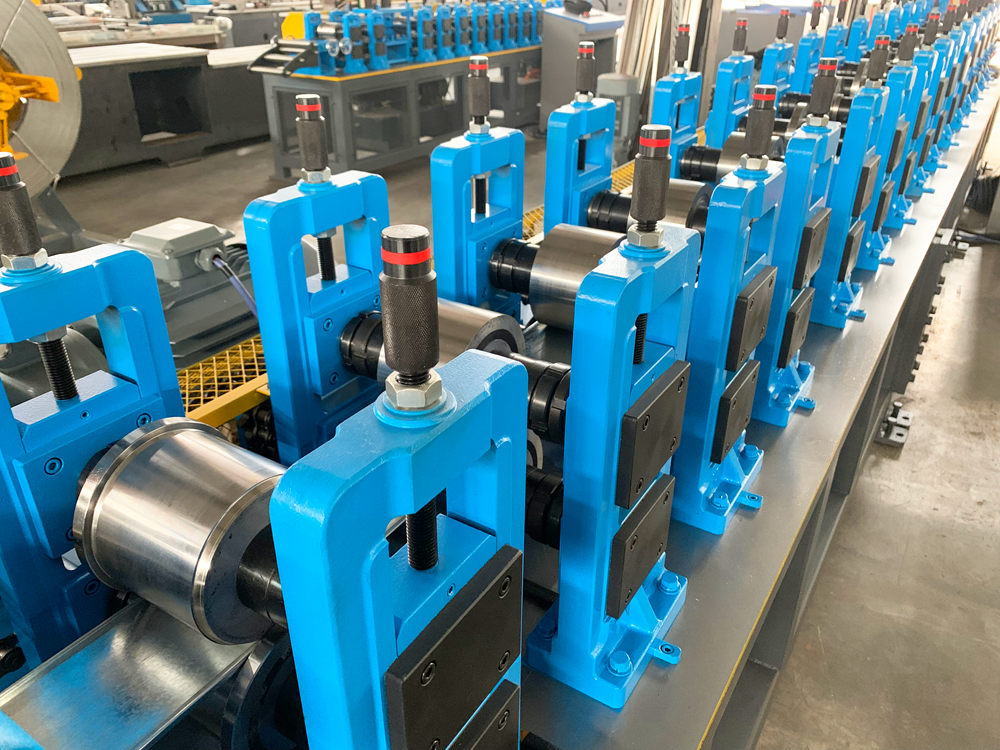

downspout roll forming machine

Industry authorities emphasize the importance of reliability and precision in such equipment. Leading manufacturers have designed downspout roll forming machines that incorporate the latest technological advancements, including programmable logic controllers (PLCs) and real-time monitoring systems, to ensure optimal performance. These features enhance operational efficiency by providing comprehensive insights into machine functioning, facilitating timely maintenance, and reducing downtime. As a result, operators can focus more on strategic tasks than troubleshooting technical hitches, thus elevating overall productivity.

Trustworthiness in picking the right machine stems from understanding the manufacturer's reputation, warranty policies, and customer service quality. Purchasing from reputable brands known for their durability and after-sales support ensures that your investment is well-protected. Case studies and customer testimonials serve as vital resources in verifying the performance and reliability of these machines, influencing purchasing decisions significantly.

In conclusion, a downspout roll forming machine is a pivotal addition to any construction or manufacturing setup aiming for growth and excellence. This equipment embodies a blend of experience, expertise, authoritativeness, and trustworthiness—elements crucial for modern businesses striving for innovation and quality assurance. As the construction industry evolves, incorporating such advanced machinery will undoubtedly set your business apart, ensuring lasting success and customer satisfaction.