The Steel Cable Tray Making Roll Forming Machine A Revolution in Industrial Manufacturing

In the modern industrial landscape, the demand for effective electrical distribution systems has surged dramatically. As industries expand, so do their requirements for robust cable management solutions. Steel cable trays have emerged as a favored option, providing not only durability but also substantial benefits regarding safety and efficiency. At the heart of this transformative production process is the steel cable tray making roll forming machine, a sophisticated piece of machinery designed to streamline manufacturing and enhance precision in the production of cable trays.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of sheet metal, typically cold rolled steel, is fed through a series of sequential dies. Each pair of rollers progressively shapes the metal into the desired profile, creating a uniform, high-quality product. For the production of steel cable trays, this technique offers numerous advantages over traditional methods such as fabrication or welding.

One of the primary benefits of roll forming is its efficiency. The process allows the creation of long sections of cable trays without the need for additional cutting or welding, significantly reducing production time. Furthermore, because the material is cold-formed, it retains its mechanical properties, achieving a stronger end product. This method also minimizes waste, as the strip of metal can be shaped into cable trays with minimal scrap material.

Features of the Steel Cable Tray Making Machine

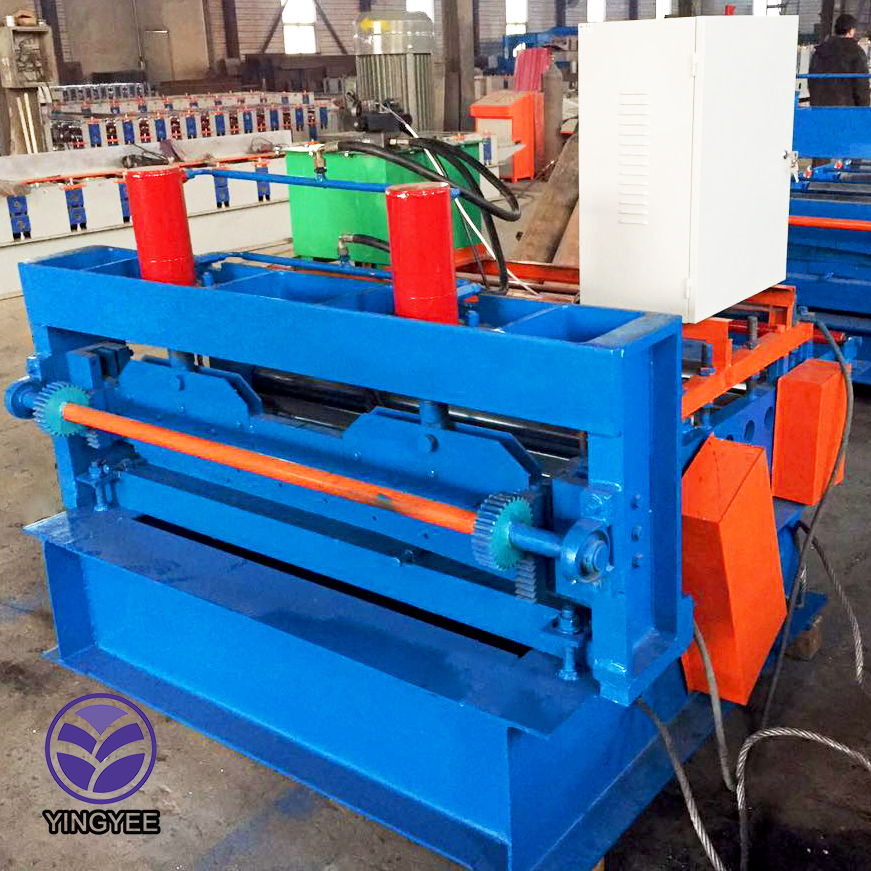

The steel cable tray making roll forming machine incorporates advanced features that enhance its operational effectiveness. Key components typically include

1. Roller Configuration The machine is equipped with numerous rollers, each precisely engineered to achieve specific bends and angles. This design allows for the creation of a variety of tray configurations, catering to diverse industry requirements.

2. Automated Controls Modern roll forming machines feature computerized controls that enable operators to program various parameters, such as speed and tray dimensions, ensuring consistency and accuracy in production.

4. Durability and Maintenance Constructed from high-quality materials, roll forming machines are designed to withstand the rigors of industrial use. Furthermore, ease of maintenance is a significant consideration, ensuring minimal downtime and continuous operation.

Applications and Market Demand

Steel cable trays produced by roll forming machines are widely used across various sectors, including construction, telecommunications, and energy. These trays serve as essential components in safely routing and protecting electrical cables, contributing to the overall reliability and safety of electrical systems.

The global market for cable trays is expected to witness significant growth, driven by increasing urbanization, infrastructure development, and the expansion of renewable energy projects. As industries strive for more organized and efficient cable management systems, the demand for durable steel cable trays continues to rise. This trend underscores the importance of efficient manufacturing processes facilitated by advanced roll forming technology.

Conclusion A Future of Innovation

The steel cable tray making roll forming machine represents a convergence of innovation, efficiency, and quality in industrial manufacturing. As industries grow and evolve, the ability to produce high-quality cable trays with precision will be paramount. The adaptability of roll forming technology positions it as a leading method for manufacturing not only cable trays but also a wide range of metal products.

Investing in such machinery not only enhances productivity but also supports sustainability efforts by reducing waste and energy consumption during production. As technologies continue to advance, the role of the steel cable tray making roll forming machine will undoubtedly expand, setting the standard for excellence in the manufacturing of essential infrastructure components. The future holds immense potential for those who embrace this technological evolution, paving the way for a new era in industrial manufacturing.