Understanding the Shelf Rack Upright Roll Forming Machine A Key Component in Modern Warehousing

In today’s rapidly evolving industrial landscape, efficiency and space optimization are paramount, particularly in warehousing and retail environments. One of the pivotal technologies that have emerged to address these needs is the shelf rack upright roll forming machine. This innovative equipment plays a crucial role in the production of metal storage solutions, significantly enhancing functionality and cost-effectiveness.

What is a Shelf Rack Upright Roll Forming Machine?

A shelf rack upright roll forming machine is a specialized piece of equipment designed to manufacture the upright components of shelving units used in warehouses, retail spaces, and distribution centers. These machines utilize a continuous process to shape metal sheets into the upright structures that form the backbone of shelving systems. The primary materials used are cold-rolled steel or galvanized steel, which offer the necessary strength and durability to support heavy loads.

How Does It Work?

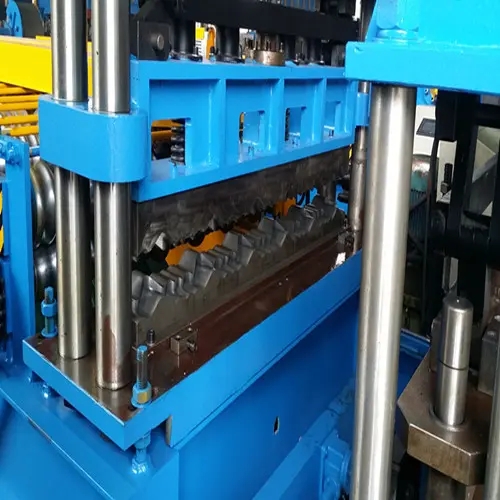

The operation of a shelf rack upright roll forming machine involves several key stages. Initially, a flat steel sheet is fed into the machine, where a series of rollers progressively shape the metal into the desired profile. The machine ensures consistent dimensions and high precision, allowing for various designs that can accommodate different weight capacities and shelf configurations.

One of the critical features of these machines is their ability to produce uprights with precision holes and notches. These openings facilitate the adjustment of shelves at various heights, making the racks versatile and adaptable to different storage needs. Additionally, many roll forming machines incorporate automated cutting and punching tools, which enhance productivity and reduce the need for secondary operations.

Benefits of Using a Roll Forming Machine

1. Cost Efficiency By using a roll forming machine, manufacturers can significantly lower production costs. The efficiency of the process reduces wastage of materials and minimizes labor costs, resulting in higher profit margins.

2. High Production Capacity These machines are designed for continuous operation, enabling them to produce large volumes of uprights in a relatively short period. This capacity is particularly beneficial for businesses that require rapid inventory turnover.

3. Customization The adaptability of shelf rack upright roll forming machines allows manufacturers to customize products according to client specifications. This flexibility is essential in a market that demands tailored solutions.

4. Durability and Strength The materials used in creating these racks ensure that they can stand up to heavy loads, making them suitable for various applications, from retail to industrial storage.

5. Ease of Installation The precise manufacturing process ensures that the uprights fit together seamlessly during assembly, significantly reducing installation time and effort.

The Future of Shelf Rack Systems

As industries continue to grow and evolve, the demand for innovative storage solutions will only increase. Advances in roll forming technology, such as automation and smarter manufacturing processes, promise to enhance the capabilities of shelf rack upright production. Furthermore, sustainability concerns are prompting manufacturers to explore eco-friendly materials and practices, leading to the development of greener production techniques.

In conclusion, the shelf rack upright roll forming machine represents a vital tool in modern manufacturing, enabling businesses to meet the demands of efficient storage and organization. As these machines advance, they will not only improve operational efficiencies but also contribute to the broader goals of sustainability and innovation in the supply chain. Investing in such technology is crucial for businesses looking to optimize their operations and remain competitive in today’s market.