Guardrail block cold bending machines have revolutionized the manufacturing industry with their precision engineering and efficiency. Aimed at industries engaged in road safety and infrastructure development, these advanced machines are indispensable tools for fabricating high-grade guardrails.

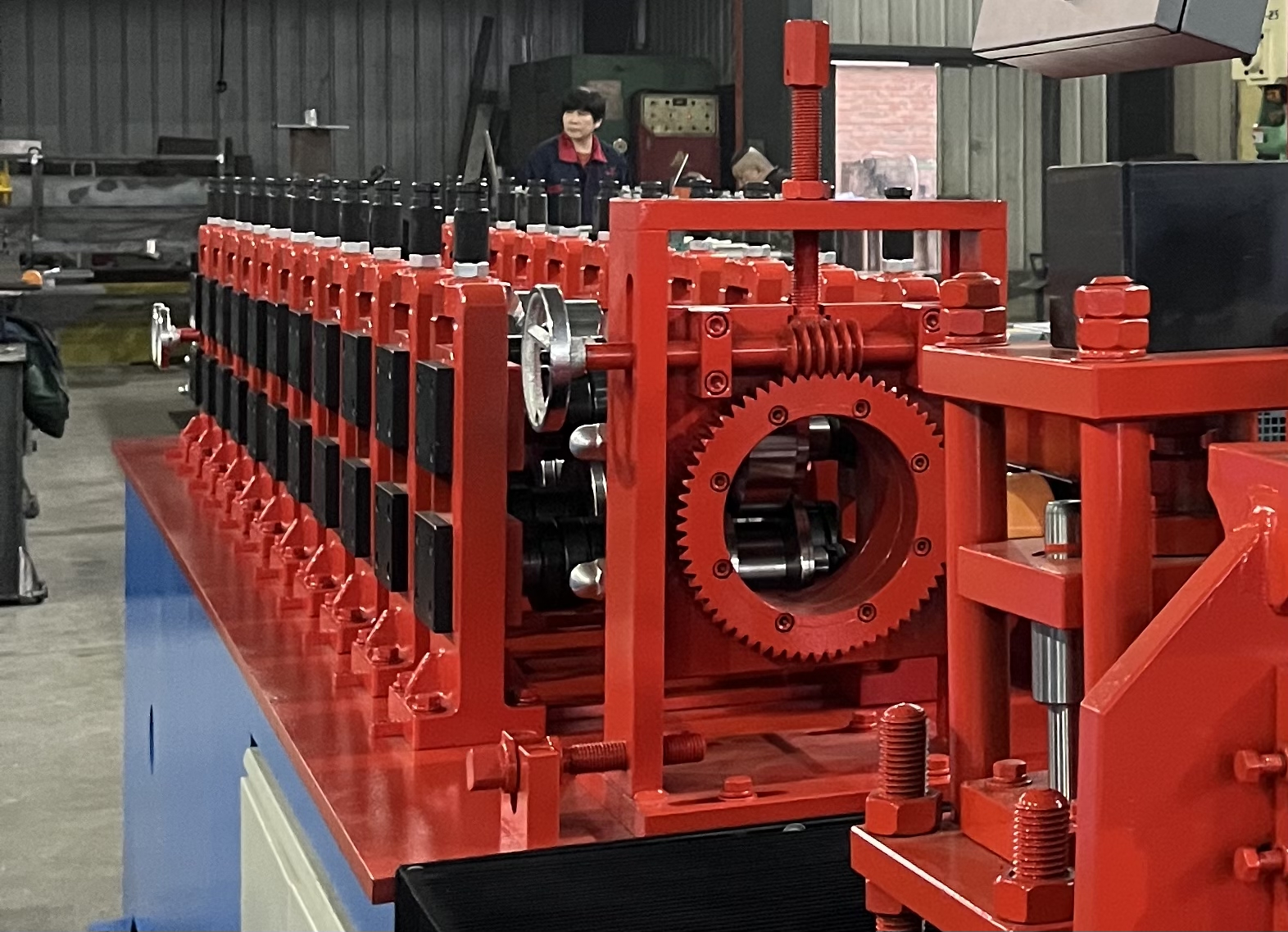

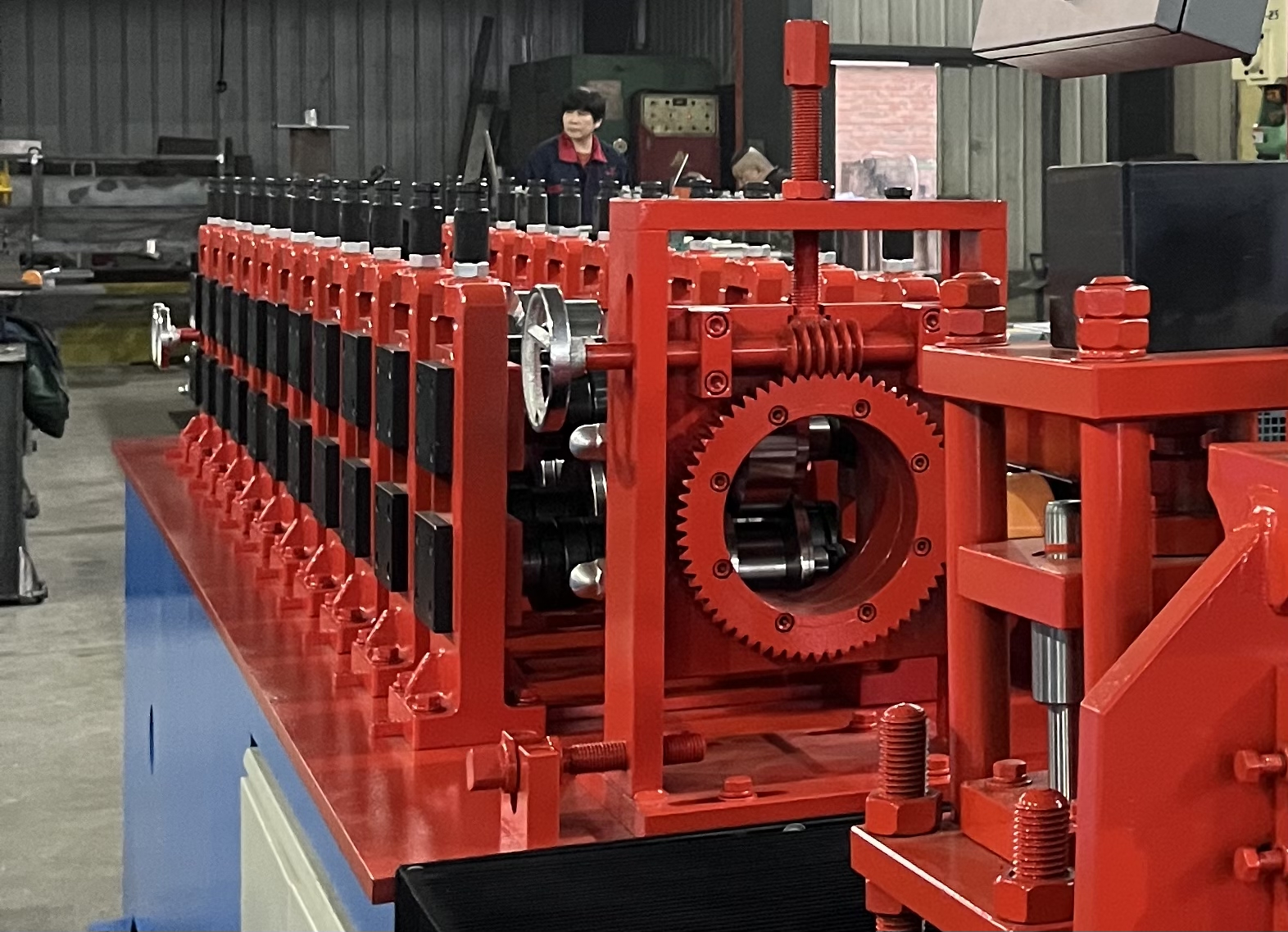

A firsthand dive into the operational dynamics of a guardrail block cold bending machine reveals the synergy between engineering prowess and cutting-edge technology. Operators familiar with these machines assert that their ability to bend heavy-duty materials with exact specifications is unmatched. This machine’s design reflects a deep understanding of the demands of construction and safety sectors, ensuring outputs that meet strict regulatory standards.

The essence of a guardrail block cold bending machine lies in its process adaptability and operational efficacy. Experts emphasize that this machine accommodates a wide range of metal grades, making it versatile for numerous applications. Its design is rooted in the principles of structural engineering and thermodynamics, ensuring that the bending process maintains the material’s integrity without inducing stress fractures or compromising its tensile strength. Engineers advocate for the best practices in maintenance and operation to extend the machine's lifespan, thus guaranteeing return on investment through sustained performance and minimal downtimes.

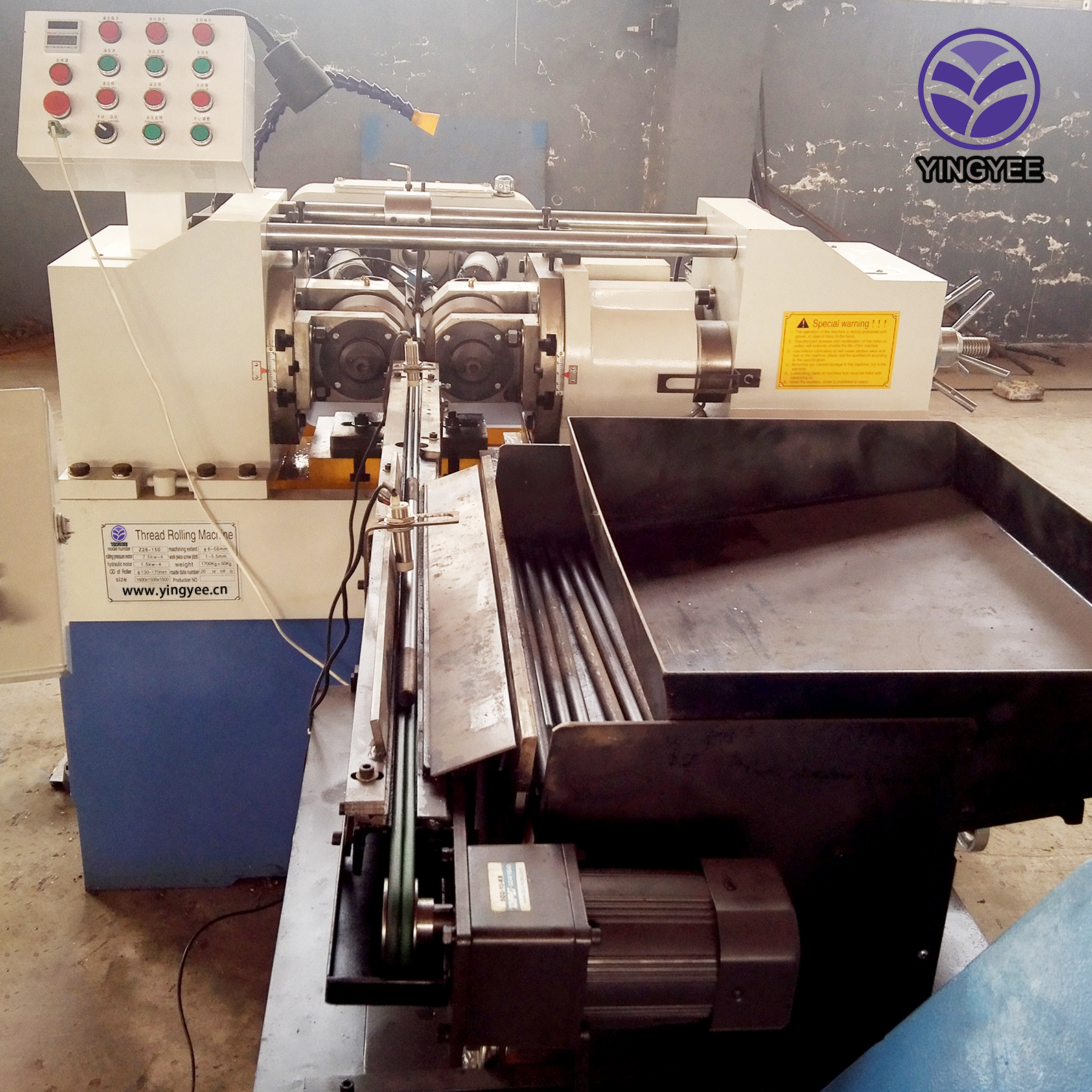

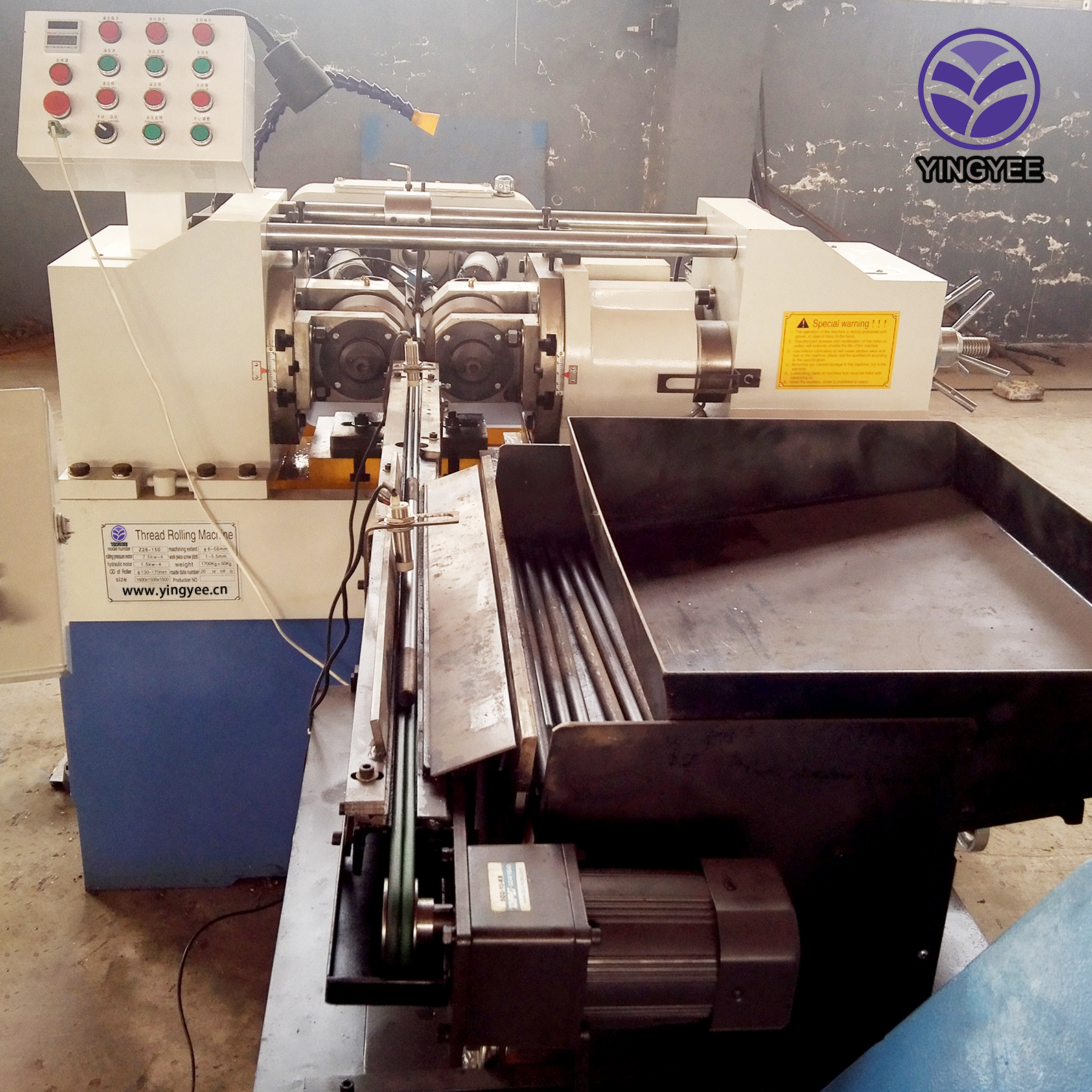

Manufacturers of guardrail block cold bending machines underscore the importance of precision calibration. The meticulous alignment of rollers and the seamless integration of hydraulic systems are critical factors that influence output quality. Industry authorities maintain that periodic training sessions for operators ensure that they remain adept at handling the sophisticated functionalities of these machines. This knowledge transfer is not only a testament to the expertise within the field but also a pledge to uphold production standards that meet international safety regulations.

Credibility in the manufacturing sector is intrinsically linked to the reliability of machinery. Guardrail block cold bending machines are no exception, and procuring this equipment from accredited suppliers is of paramount importance. Testimonials attest to the machine’s ability to deliver consistent and uniform bends, even when subjected to rigorous operational cycles. Trust is reinforced through transparent documentation and adherence to safety protocols, ensuring that end-users receive a machine that stands the test of time.

guardrail block cold bending machine

Exploring the cutting-edge technologies embedded in guardrail block cold bending machines unveils a panorama of innovation. The incorporation of automated control systems minimizes human error, enhancing precision and output consistency. Real-time monitoring through integrated software provides operators with critical insights, enabling adjustments that optimize performance and reduce waste. Expertise in programming these control systems aligns with the industry’s shift towards digital solutions, positioning the machine as a vanguard in manufacturing technology.

From an investment perspective, the acquisition of a guardrail block cold bending machine is strategic for businesses aiming to scale operations and enhance their service offerings. The machine’s agility in adapting to diverse project requirements makes it a versatile asset that supports the diversification of a company’s portfolio. Business analysts advocate for a thorough assessment of potential suppliers, evaluating their credibility and industry standing to ensure compliance with quality benchmarks.

In conclusion, guardrail block cold bending machines embody the synthesis of expertise and innovation in high-stakes manufacturing environments. The profound understanding of material science, engineering principles, and digital technology coalesces into a machine that not only fulfills but exceeds industry expectations. As manufacturers continue to harness these machines, they pave the way for an infrastructure that underscores safety and reliability, reinforcing their role as critical stakeholders in industrial advancement.

This authentically crafted exploration serves as an authoritative resource for decision-makers considering the integration of guardrail block cold bending machines into their operations, supporting them with insights grounded in experience, expertise, and trustworthiness.