The Well Finishing Wall Angle Roll Forming Machine Revolutionizing Construction with Precision and Efficiency

In the modern construction industry, the demand for precision-engineered materials continues to rise. Among the array of equipment that aids in the manufacturing process, the well finishing wall angle roll forming machine has emerged as a crucial asset for builders and manufacturers alike. This machine is specifically designed to produce high-quality wall angles used in construction, offering numerous benefits in terms of efficiency and accuracy.

What is a Wall Angle Roll Forming Machine?

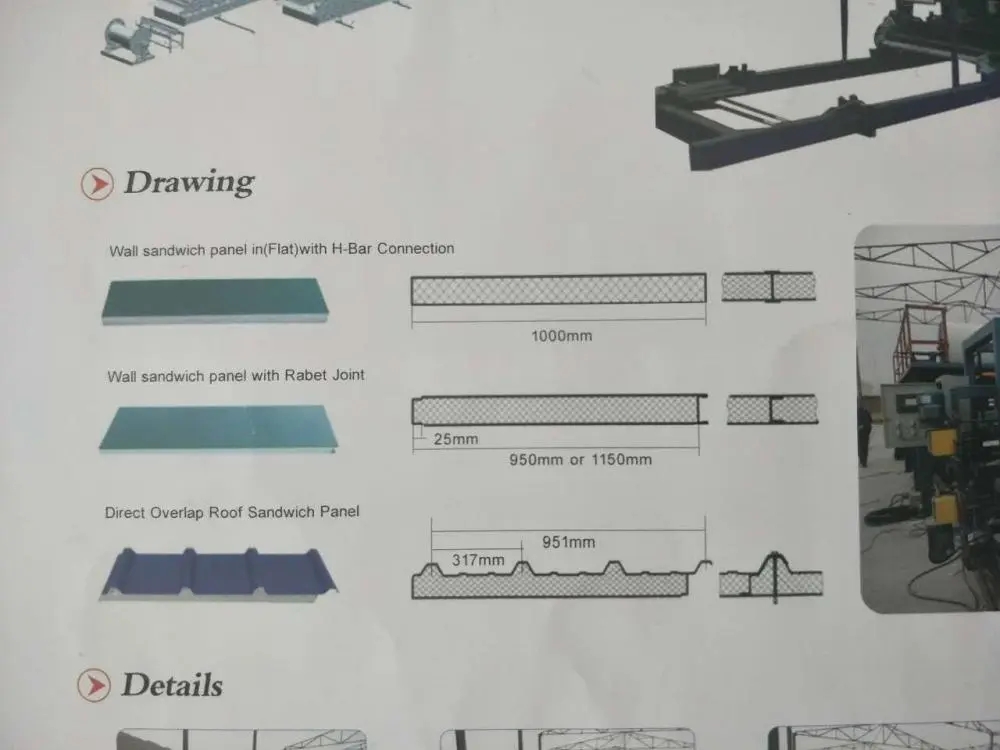

A wall angle roll forming machine is a type of industrial equipment used to manufacture wall angles, which are L-shaped metal profiles that provide structural support and are commonly utilized in framing systems for drywall or paneling. These machines leverages advanced roll forming technology, wherein metal coils are fed into the machinery and progressively shaped into the desired profile through a series of rollers. The well finishing aspect of the machine refers to the precision finishing processes that ensure the angles produced are of the highest quality, free from defects, and ready for immediate use in construction applications.

Advantages of Using a Well Finishing Wall Angle Roll Forming Machine

1. High Precision and Consistency One of the primary advantages of using a wall angle roll forming machine is the consistency and precision it provides. Unlike manual methods, the automated process reduces human error and guarantees that each profile produced meets exact specifications. This reliability is crucial for construction projects where structural integrity is paramount.

2. Enhanced Production Efficiency The automation involved in roll forming significantly speeds up production rates. With the ability to create long runs of wall angles in a fraction of the time it would take to cut and shape metal manually, manufacturers can meet tight deadlines without compromising quality.

3. Cost-Effectiveness Although the initial investment in a wall angle roll forming machine can be considerable, the long-term savings in labor costs and material waste make it a cost-effective solution. Moreover, the durability of the finished products leads to reduced replacement and repair costs over time.

4. Customization Capabilities Many advanced models of wall angle roll forming machines come equipped with software that allows for easy customization. This means manufacturers can quickly adjust specifications to create different sizes and shapes of wall angles to fit various project needs without the need for extensive retooling.

5. Better Material Utilization Roll forming is known for its efficiency in material usage. The process minimizes scrap metal, leading to less waste and more environmentally friendly practices. This is increasingly important in a world striving for sustainable construction solutions.

Applications of Well Finishing Wall Angles

Wall angles are fundamental in a variety of applications within the construction industry. They are primarily used in

- Framing Systems Providing support for drywall and ensuring a proper fit and alignment. - Suspended Ceilings Acting as a crucial component in the grid systems that support ceiling tiles. - Interior Design Enhancing the aesthetic appeal of spaces through decorative installations.

Conclusion

As the construction industry evolves, tools like the well finishing wall angle roll forming machine are becoming indispensable. Not only do they enhance the quality and speed of production, but they also align with the industry's shift towards greater efficiency and sustainability. Manufacturers who adopt this technology are better positioned to thrive in a competitive market, ensuring that their products not only meet but exceed the expectations of modern construction demands. In summary, investing in a well finishing wall angle roll forming machine is not just a choice for enhanced productivity; it is a strategic move towards future-ready manufacturing.