Understanding the importance of precise manufacturing processes in the automotive industry, the truck fender cold bending machine stands out as a revolutionary piece of equipment. Offering unparalleled capabilities in forming robust fender components, this machine is a game-changer for manufacturers aiming for efficiency and quality.

In an era where every industry strives for innovation, the role of a truck fender cold bending machine is crucial in meeting specific design and strength requirements. This machinery is adept at cold-forming metal sheets into intricate and precise fender shapes without compromising the material's integrity. This method, unlike traditional hot bending processes, maintains the inherent strength and structural stability of the metal due to lower thermal stress. This is vital when forming parts that must endure continual wear and tear.

Expert manufacturers reveal that the cold bending machine's precision is not an accident but the result of years of engineering expertise. Designed with state-of-the-art software and hardware components, these machines offer unmatched scalability and flexibility. They allow operators to transition from one truck model's fender to another with minimal downtime, making them indispensable in a competitive automotive landscape.

The machine’s efficiency is further amplified through its user-friendly interface, which reduces operator error and increases productivity. Each unit tends to come equipped with an intelligent control system that allows operators to input specific parameters for each design. This function ensures fender edges are smooth, uniform, and perfectly aligned to the truck's specifications.

Real-world experiences from trusted manufacturers highlight the machine’s ability to decrease production time significantly. By eliminating the need for excessive heating, the cold bending process reduces energy consumption, thus lowering operational costs. Companies that have integrated these machines into their production lines often report increased throughput, better product consistency, and a noticeable decrease in material wastage.

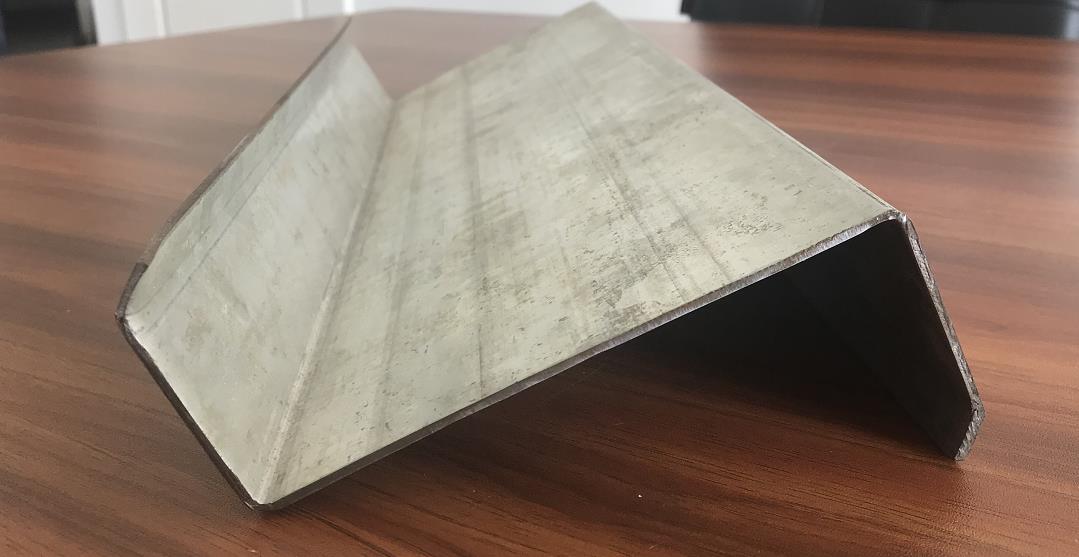

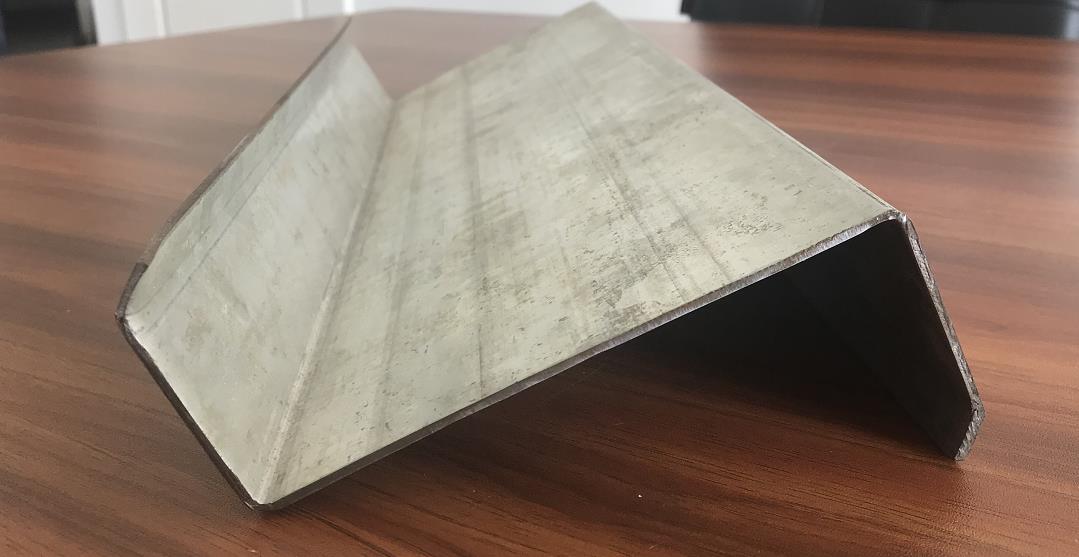

truck fender cold bending machine

The truck fender cold bending machine’s engineering brilliance is further supported by testimonials from industry leaders who endorse its impact on manufacturing standards. Renowned automotive parts manufacturers attest to the machine's capability to produce fenders that meet rigorous safety standards. This endorsement not only reaffirms the machine’s essential role in production but also underscores its contribution to vehicular safety and reliability.

From a sustainability perspective, cold bending technology offers environmental benefits by fostering a cleaner production process. The elimination of heating elements reduces carbon emissions and chemical treatments, aligning with global sustainability goals.

Manufacturers that prioritize environmentally responsible processes find the cold bending machine an ideal fit for their green initiatives.

Trustworthiness is another integral factor that manufacturers consider when selecting a truck fender cold bending machine. Machines procured from reputable suppliers come with warranty assurances and after-sale services, including routine maintenance checks and technician support, to ensure optimal operation over time.

Furthermore, industry experts emphasize the need for staff training to ensure the machine's effective utilization. Skilled operators are critical in maximizing the machine's potential, and many manufacturers invest in comprehensive training programs to bridge any skills gap. Such investments in human capital not only enhance machine performance but also promote safety and job satisfaction among operators.

In summary, the truck fender cold bending machine is transformative for any operation focused on delivering high-quality automotive components. Combining expertise-driven design with cutting-edge technology, these machines embody reliability, efficiency, and environmental consciousness. As manufacturers continue to evolve with industry demands, the adoption of cold bending processes stands as a testament to innovation in automotive manufacturing.