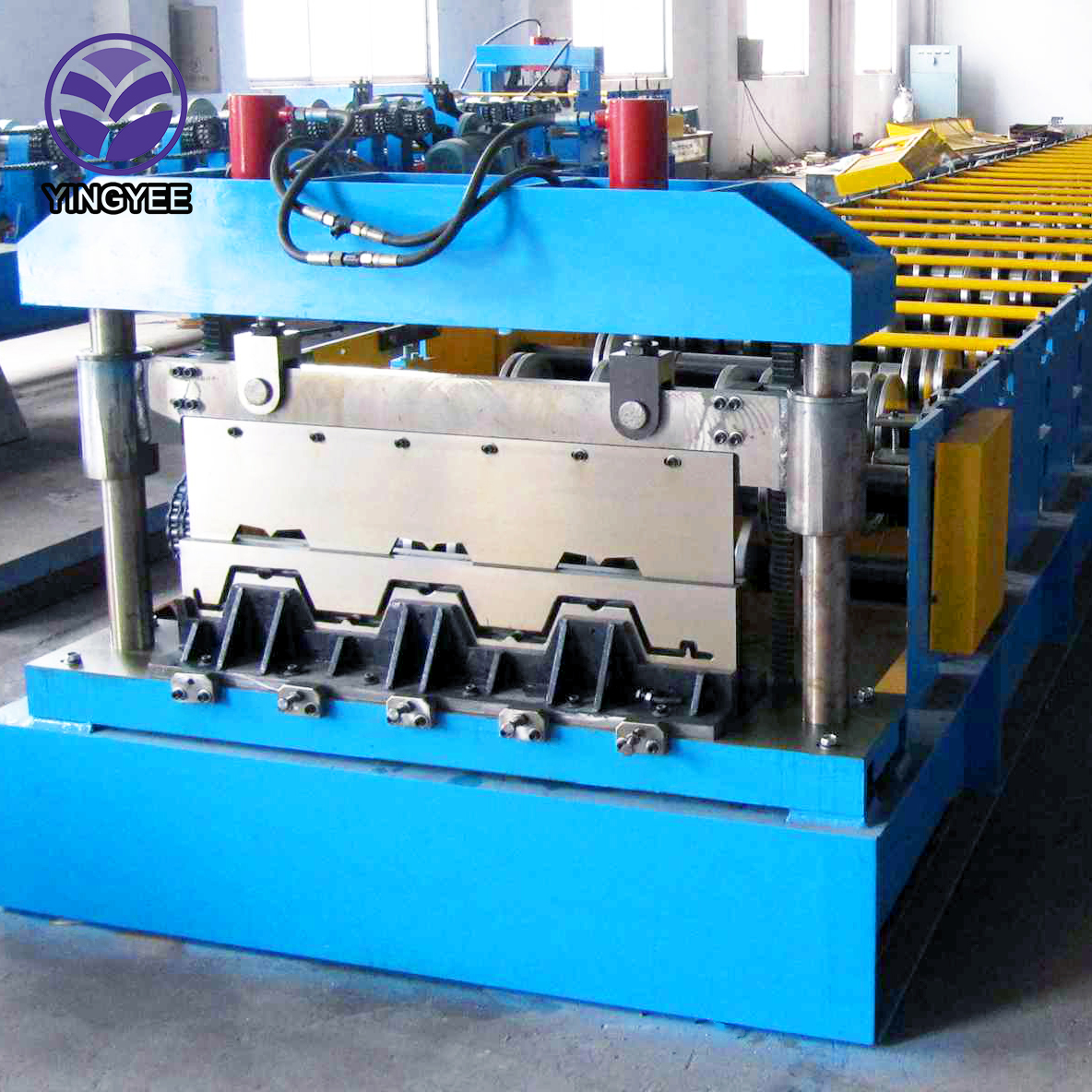

I’ve walked enough factory aisles to notice a pattern: buyers want faster changeovers, stable forming at 0.8–1.5 mm, and clean cuts without burrs. That’s why I paid attention to the “Good quality flooring deck roll forming machine” coming out of Shijiazhuang (Room B1106, Zhongliang Plaza, No.345 Youyi North Street, Xinhua District, Hebei). It’s labeled for decking, but—truth be told—the platform’s rigidity and roll-stand geometry also suit corrugated profiles with the right tooling set. Many customers say it hits the sweet spot between price and uptime.

Urban infill and fast-track roofing push for higher line speeds (≈12–18 m/min real-world), servo flying cuts, and PLC diagnostics. Frankly, the quiet trend is smarter coil handling and tighter length accuracy (±0.5 mm claimed; ±0.7 mm on a dusty Thursday—still acceptable). Sustainability nudges mills toward AZ-coated steels and recyclable packaging; machine makers now quote energy per meter formed. Not everyone measures it, but they should.

| Model | Good quality flooring deck roll forming machine (corrugated tooling optional) |

| Thickness range | 0.8–1.5 mm (steel); aluminum profiles usually 1.0–1.2 mm |

| Forming speed | ≈12–18 m/min (real-world use may vary) |

| Coil width | 900–1250 mm (custom width sets available) |

| Power | Main motor ≈11–18.5 kW; hydraulic station ≈4–5.5 kW |

| Length accuracy | ±0.5 mm per cut (test run: 100 pcs, σ ≈0.22 mm) |

| Certifications | ISO 9001, CE (Machinery Directive), EN 60204-1 electrical |

Advantages I noticed: stable bed (less chatter on 1.2 mm), straightforward HMI, and tooling that doesn’t mark PPGI if the line is cleaned properly. It seems that operators like the recipe memory—switching profiles is still a wrench job, but offsets load instantly.

| Vendor | Speed | Thickness | Control | Warranty | Price (≈) |

|---|---|---|---|---|---|

| YingYee deck/corrugated platform | 12–18 m/min | 0.8–1.5 mm | PLC + encoder | 18 months | Mid |

| Generic Vendor A | 10–14 m/min | 0.5–1.2 mm | Basic PLC | 12 months | Low |

| Local Fabricator B | 14–16 m/min | 0.7–1.4 mm | PLC + HMI | 12–18 months | Mid–High |

Tooling for corrugated waves (custom pitch/depth), emboss options, servo flying cut, quick-change cassettes, coil car, and oiling units. Noise abatement and guarding per EN ISO 13857 on request. To be honest, spend on the decoiler—smooth feed makes or breaks your finish.

Shop trial (PPGI, 0.9 mm, Z275): 15 m/min average, 3000 m run, no visible paint cracking at bends; cut squareness 90° ±0.3°, scrap rate 0.8%. Another client forming 1.2 mm AZ sheet said maintenance dropped after switching to filtered hydraulic oil—small thing, big payoff.

A prefab builder outfitted one line for deck and a second with corrugated tooling. Lead time fell from 21 to 9 days. The operator joked, “It’s boring now… which is exactly what we want.” That’s the vibe a solid corrugated roof sheet making machine should give: predictable.

Citations: [1] ISO 9001:2015 Quality Management Systems. [2] ASTM A653/A653M – Steel Sheet, Zinc-Coated (Galvanized). [3] ASTM A792/A792M – Steel Sheet, 55% Al-Zn-Coated. [4] EU Machinery Directive 2006/42/EC; EN 60204-1.